Carbon-supported metal catalyst and preparation method and application thereof

A technology for supporting metals and catalysts, applied in the field of carbon-supported metal catalysts and their preparation, to achieve the effects of improving efficiency, low equipment requirements, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of any one of the above-mentioned carbon-supported metal catalysts in one embodiment comprises the following steps:

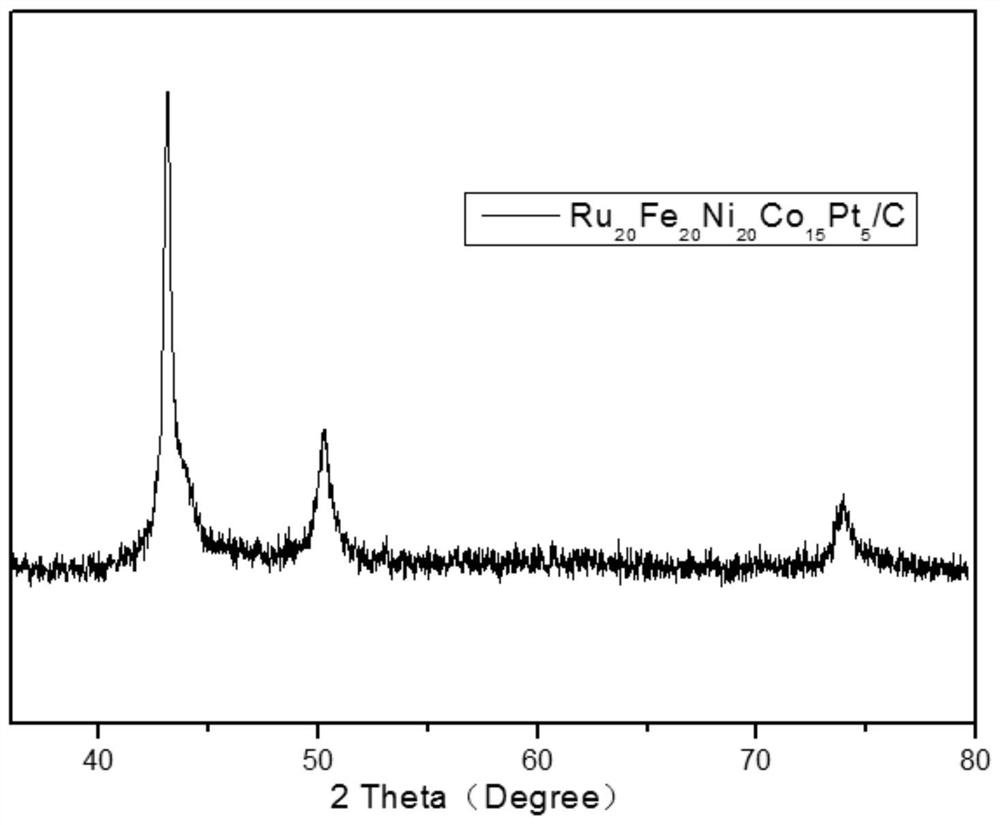

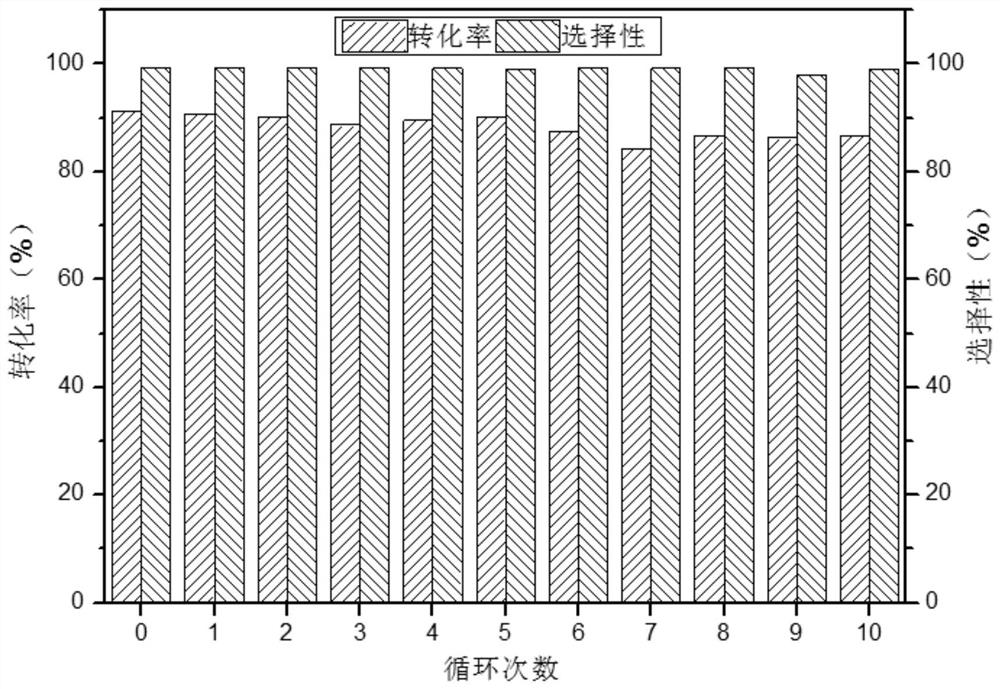

[0043]Mix carbon carrier, ruthenium precursor, iron precursor, cobalt precursor, nickel precursor, platinum precursor and reducing agent uniformly, react completely at 200°C-230°C, then separate solid from liquid and keep the solid to obtain Carbon-supported metal catalyst; the carbon-supported metal catalyst includes a carbon carrier and high-entropy alloy particles supported on the surface of the carbon carrier, and the high-entropy alloy particles include ruthenium, iron, cobalt, nickel and platinum.

[0044] Wherein, the carbon carrier is activated carbon or graphene. Among them, ruthenium precursors, iron precursors, cobalt precursors, nickel precursors, and platinum precursors are respectively used as ruthenium sources, iron sources, cobalt sources, nickel sources, and platinum sources to provide ruthenium ions, iron ions, co...

Embodiment 1

[0068] Take 246.9 mg of activated carbon, 15.9 mg of ruthenium acetylacetonate, 14.1 mg of iron acetylacetonate, 10.3 mg of nickel acetylacetonate, 7.7 mg of cobalt (II) acetylacetonate and 3.9 mg of platinum acetylacetonate, and put them into the lining of a polytetrafluoroethylene reactor. Afterwards, 70 mL of methanol was added, and the mixture was kept at 220° C. for 10 h in a hydrothermal box.

[0069] After the reaction is complete, cool down, then add ethanol for suction filtration, and then deionized water for suction filtration to obtain a solid, and dry the solid in a vacuum drying oven at a drying temperature of 70°C and a drying time of 8 hours. That is, the carbon-supported metal catalyst of Example 1 was obtained.

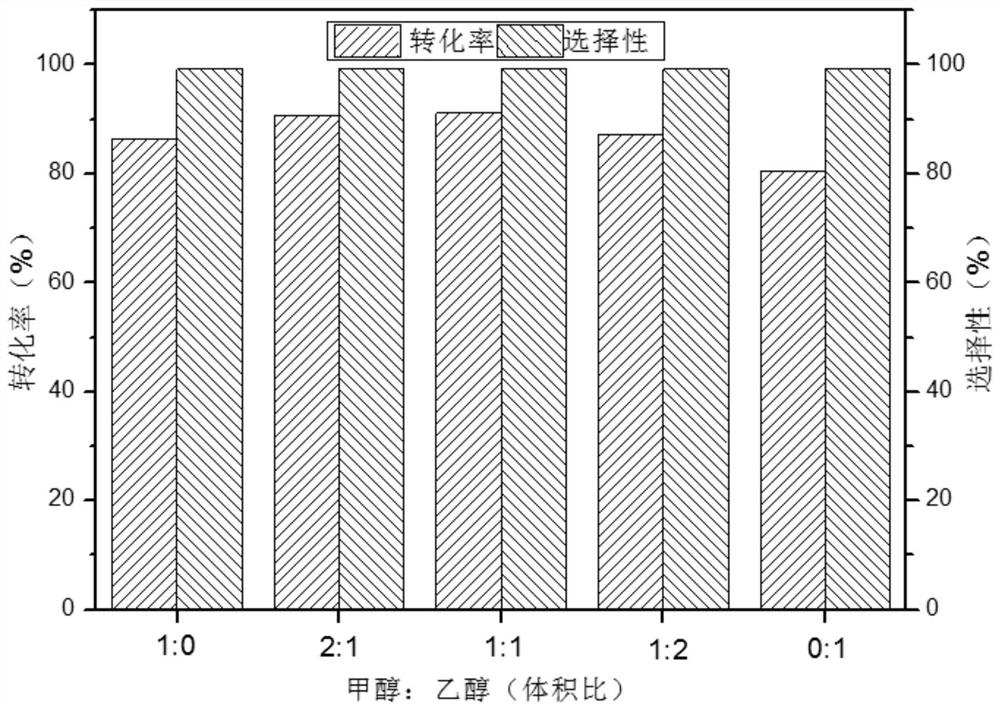

Embodiment 2

[0071] Take 246.9 mg of activated carbon, 15.9 mg of ruthenium acetylacetonate, 14.1 mg of iron acetylacetonate, 10.3 mg of nickel acetylacetonate, 7.7 mg of cobalt (II) acetylacetonate and 3.9 mg of platinum acetylacetonate, and put them into the lining of a polytetrafluoroethylene reactor. After that, 46.7 mL of methanol and 23.3 mL of ethanol were added, and the mixture was incubated at 220° C. for 10 h in a hydrothermal tank.

[0072] After the reaction is complete, cool down, then add ethanol for suction filtration, and then deionized water for suction filtration to obtain a solid, and dry the solid in a vacuum drying oven at a drying temperature of 70°C and a drying time of 8 hours. That is, the carbon-supported metal catalyst of Example 2 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com