Color-changing box-type transformer substation

A box-type substation and color-changing layer technology is applied in distribution substations, substation/distribution device enclosures, substation/switch layout details, etc. Safety, moisture reduction, easy spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

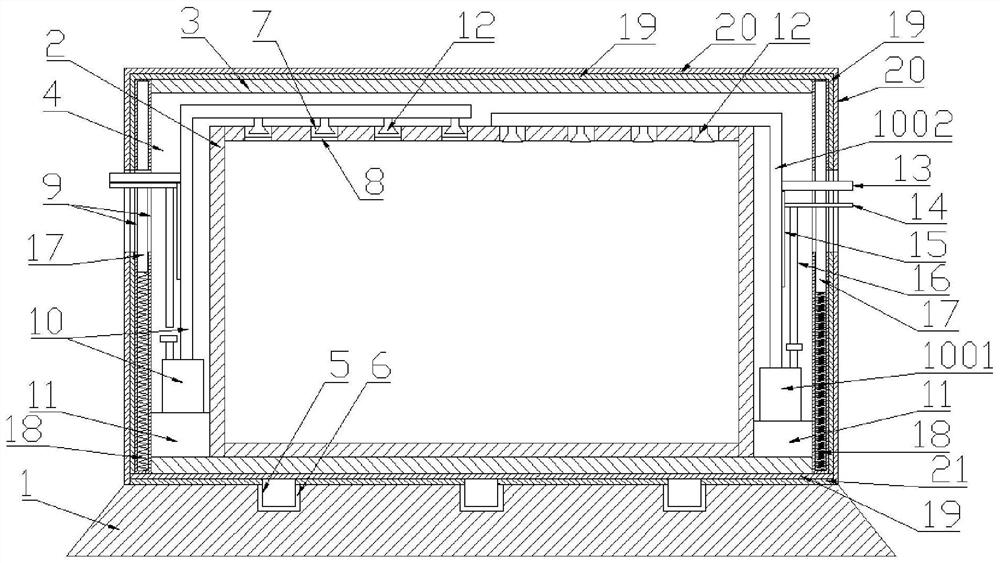

[0040] Such as figure 1 As shown, the present invention provides a color-changing box-type substation, including a base 1, a box-type substation body is installed above the base 1, and the body includes a housing A2 and a housing B3 sleeved outside the housing A2;

[0041] The bottom plate of the shell A2 is attached to the bottom plate of the shell B3, so that a cavity A4 is formed between the shell A2 and the shell B3;

[0042] A hanging ring 5 is welded under the bottom plate of the housing B3, and a groove 6 matching the hanging ring 5 is provided on the base 1. During installation, the sling is passed through the hanging ring 5 to improve the stability of the box-type substation during hoisting;

[0043] The top plate of the housing A2 is provided with a plurality of through holes A7, and rubber plugs 8 are plugged in the through holes A7, and the rubber plugs 8 play a role in sealing the housing A2;

[0044] The left side and the right side of the housing B3 are respect...

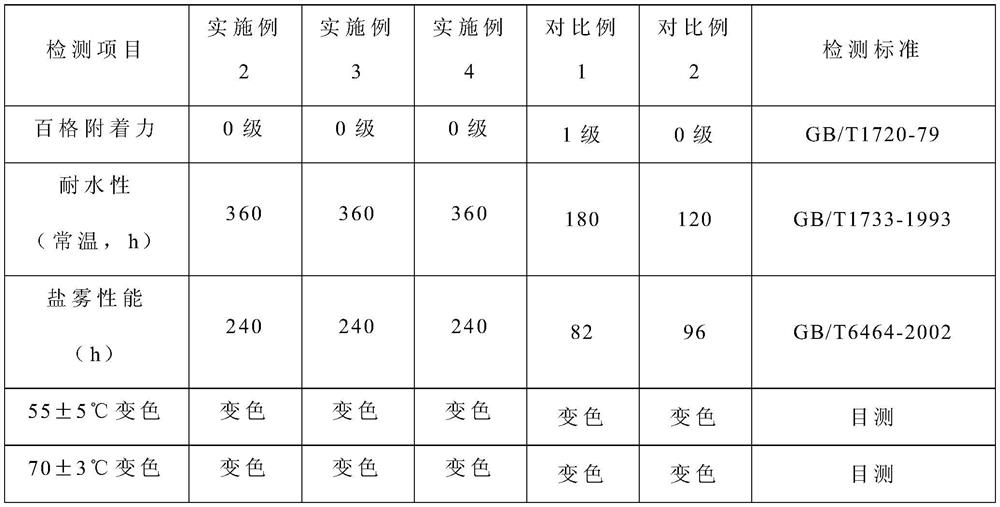

Embodiment 2

[0058] The color-changing layer that is used for embodiment 1 prepares according to following quality:

[0059] Amino resin 50kg, thermochromic powder 14kg, organic bentonite 15kg, propylene glycol butyl ether 10kg, potassium persulfate 5kg, defoamer 6.5kg, silicone leveling agent 3.8kg, deionized water 45kg.

[0060] The preparation method of the above-mentioned color-changing layer, the steps are:

[0061] (1) Amino resin, propylene glycol butyl ether, and potassium persulfate are placed in the mixer, and stirred, and the rotating speed is 3500r / min;

[0062] (2) Add 2.3kg of defoamer to (1); continue to stir at a speed of 3500r / min, then add silicone leveling agent, and stir at 3500r / min for 15min to promote the reaction between raw materials; continue to add Deionized water, stirred at 3500r / min for 30min, fully mixed raw materials with water, then added organic bentonite, stirred at 2500r / min for 10min;

[0063] (3) Add 4.2 kg of defoamer and temperature-sensitive color...

Embodiment 3

[0066] The color-changing layer that is used for embodiment 2 prepares according to following quality:

[0067] Amino resin 40kg, thermochromic powder 17kg, organic bentonite 20kg, propylene glycol butyl ether 13kg, potassium persulfate 3kg, defoamer 9kg, silicone leveling agent 2kg, deionized water 40kg.

[0068] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com