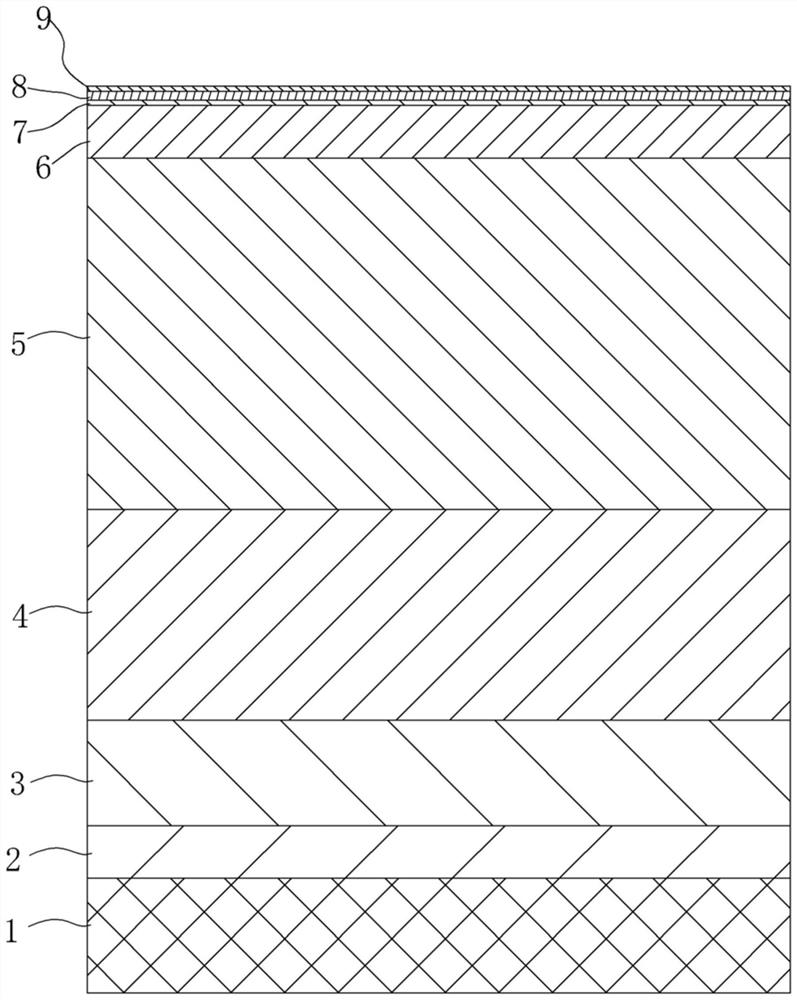

Low-loss gallium nitride radio frequency material epitaxial structure and preparation method

An epitaxial structure, gallium nitride technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as increased resistance and reduced concentration of two-dimensional electron gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

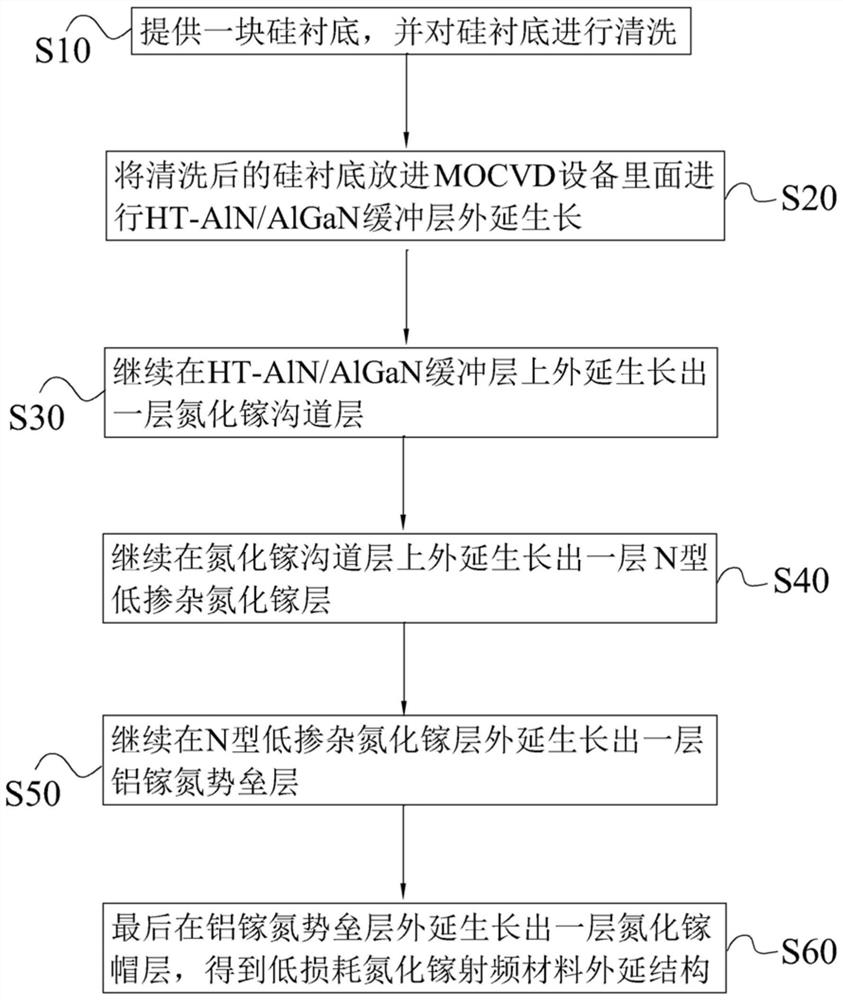

[0046] see figure 2 As shown, the present invention relates to a method for preparing a low-loss gallium nitride radio frequency material epitaxial structure, comprising the following steps:

[0047] S10, providing a silicon substrate, and cleaning the silicon substrate;

[0048] S20, putting the cleaned silicon substrate into the MOCVD equipment for epitaxial growth of the HT-AlN / AlGaN buffer layer;

[0049] S30, continuing to epitaxially grow a gallium nitride channel layer on the HT-AlN / AlGaN buffer layer;

[0050] S40, continuing to epitaxially grow an N-type low-doped GaN layer on the GaN channel layer;

[0051] S50, continuing to epitaxially grow an AlGaN barrier layer on the N-type low-doped GaN layer;

[0052] S60. Finally, a GaN cap layer is epitaxially grown on the AlGaN barrier layer to obtain a low-loss GaN radio frequency material epitaxial structure.

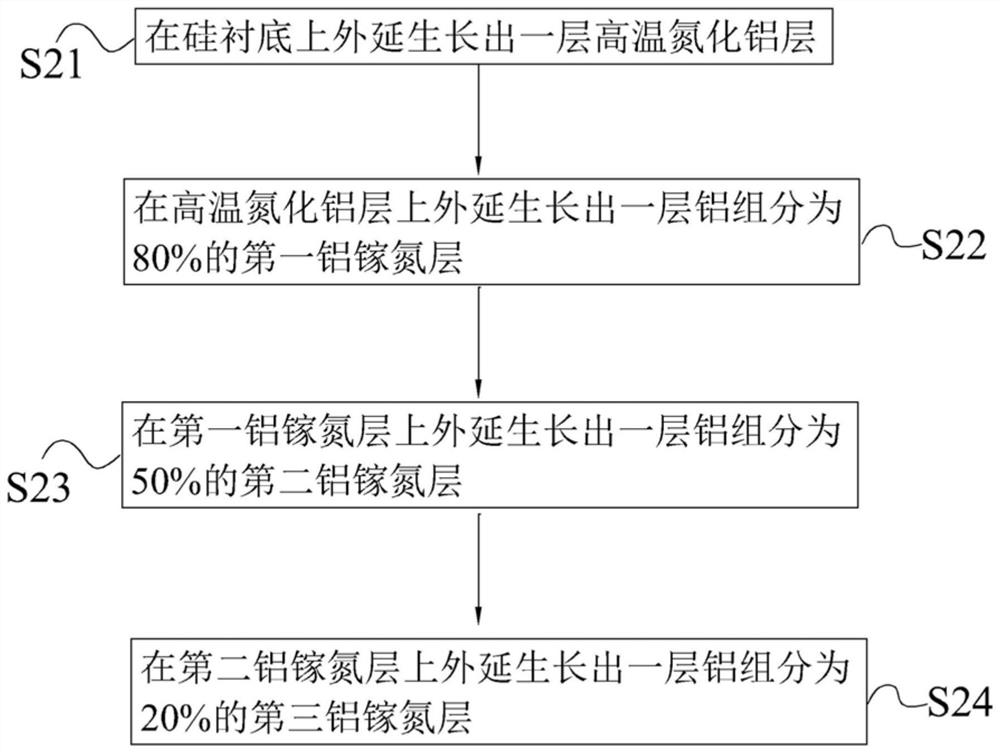

[0053] Such as image 3 As shown, in step S20, the steps of epitaxial growth of the HT-AlN / AlGaN buffer laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com