Method for manufacturing electron beam welding copper-tungsten contact piece by utilizing tungsten powder

A technology of electron beam welding and tungsten powder, which is applied in the direction of circuits, electric switches, electrical components, etc., can solve the problems of non-standard shape of sintered blanks, reduce the efficiency of post-processing, and can not add too much chromium, so as to achieve regular welding blanks, The effect of increasing the furnace loading capacity and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

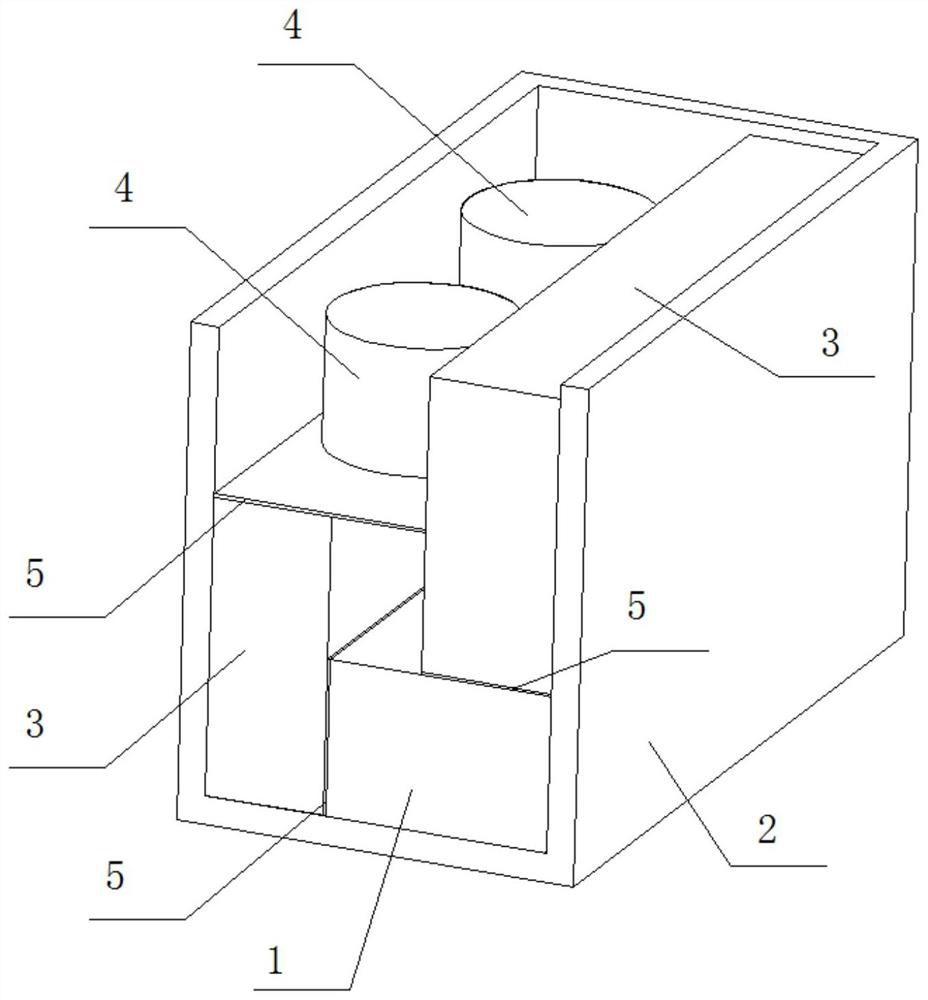

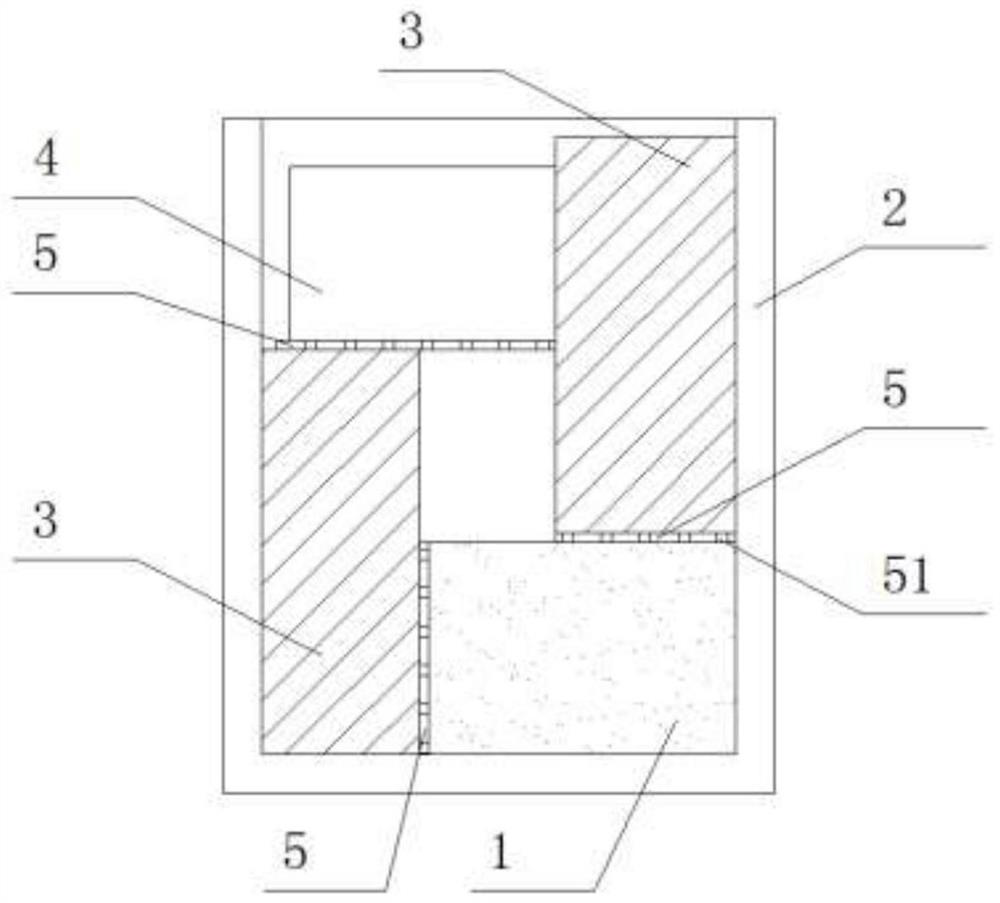

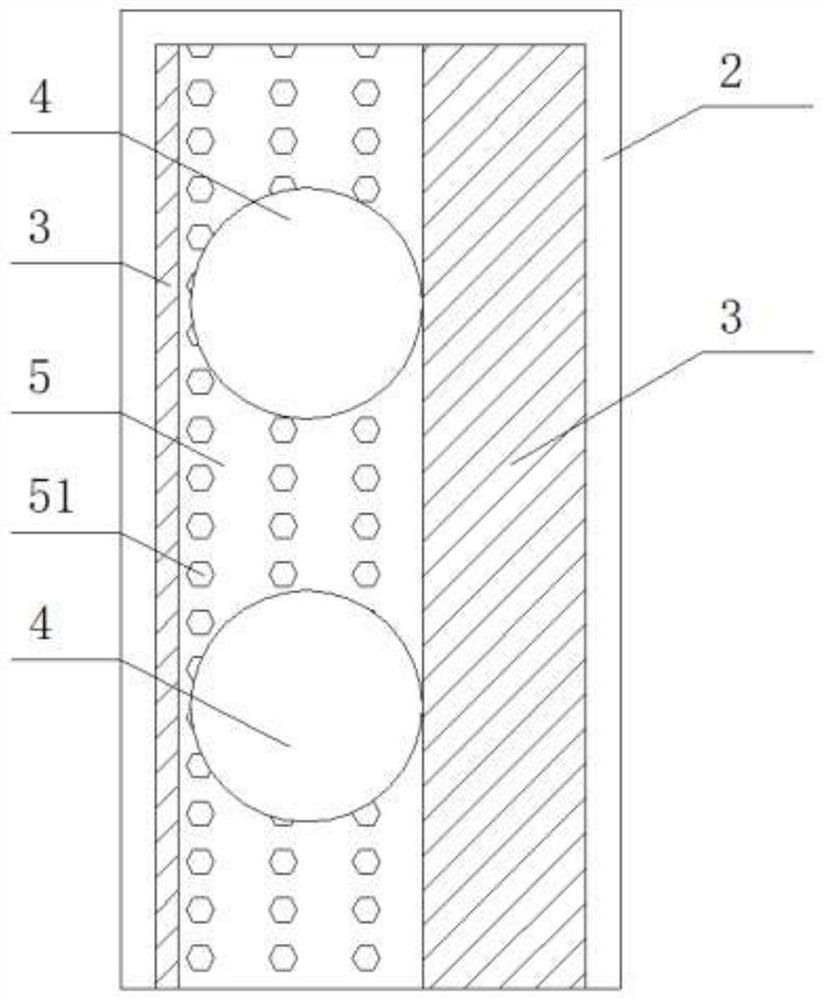

Image

Examples

Embodiment 1

[0046] A method for manufacturing electron beam welding copper-tungsten contacts by using tungsten powder, comprising the following steps:

[0047] S1 powder mixing: take an appropriate amount of tungsten powder for pretreatment, add the pretreated tungsten powder to the binder for mixing, and obtain tungsten skeleton powder; the specific steps include:

[0048]S1-1 pretreatment: Take tungsten powder with a particle size of 8.5 μm and reduce it under the protection of a reducing atmosphere at 550°C for 1 hour to obtain tungsten powder with surface activity;

[0049] S1-2 Mixing: add the tungsten powder obtained in step S11 to the binder and fully stir and mix under vacuum conditions at a temperature of 66°C. The mixing time is 12 hours. The components of the binder are oil-based binder and paraffin-based binder. Mixture, the mass ratio of the two is 100:55, and the mass ratio of binder to tungsten powder is 3.5:100;

[0050] S2 Molding: The mixed tungsten skeleton powder is u...

Embodiment 2

[0061] This embodiment is basically the same as Embodiment 1, the difference is:

[0062] Step S2 Molding: The mixed tungsten skeleton powder is unidirectionally pressed on a 200-ton hydraulic oil press to obtain a density of 10.2g / cm 3 tungsten billet;

Embodiment 3

[0064] This embodiment is basically the same as Embodiment 1, the difference is:

[0065] Step S2 Molding: Unidirectionally press the mixed tungsten skeleton powder on a 200-ton hydraulic hydraulic press to obtain a density of 10.9g / cm 3 tungsten billet;

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com