Control method of variable mass-variable rigidity composite dynamic vibration absorber

A technology of a dynamic vibration absorber and a control method, which is applied in non-electric variable control, mechanical oscillation control, shock absorber and other directions, can solve the problems of complex control process of the shock absorber, difficult practical application, and the inability to meet the requirements of the vibration reduction frequency band width, etc. Achieve simple and effective accuracy, avoid complete failure, and achieve obvious vibration reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

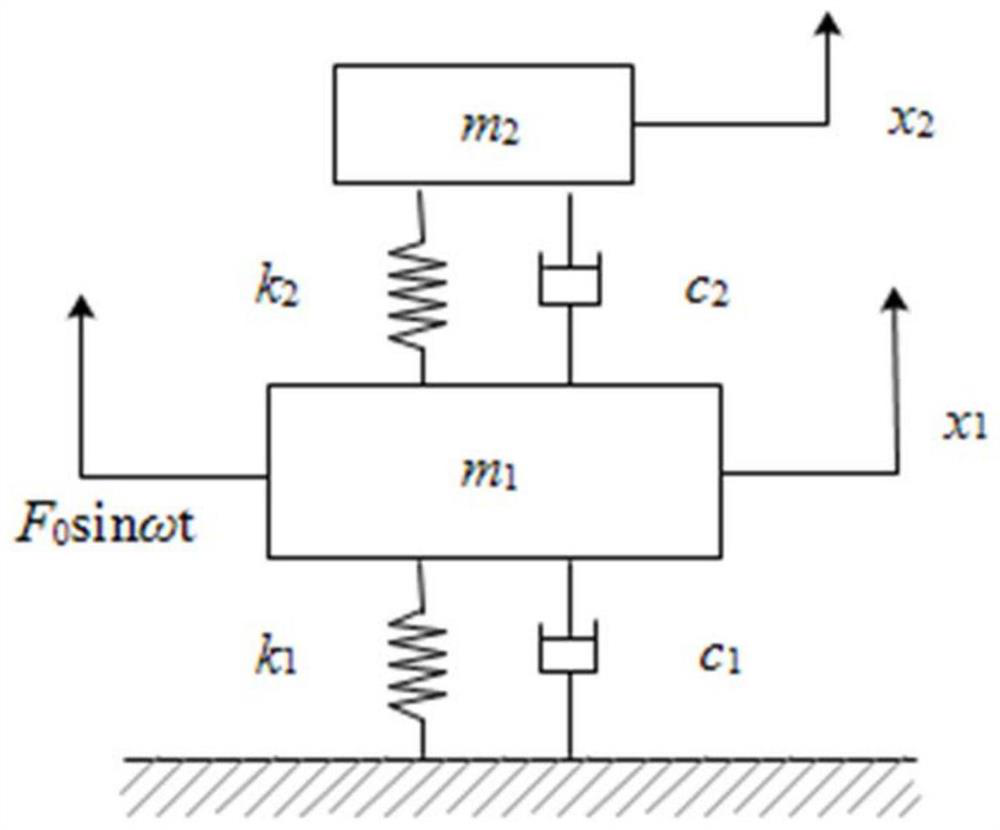

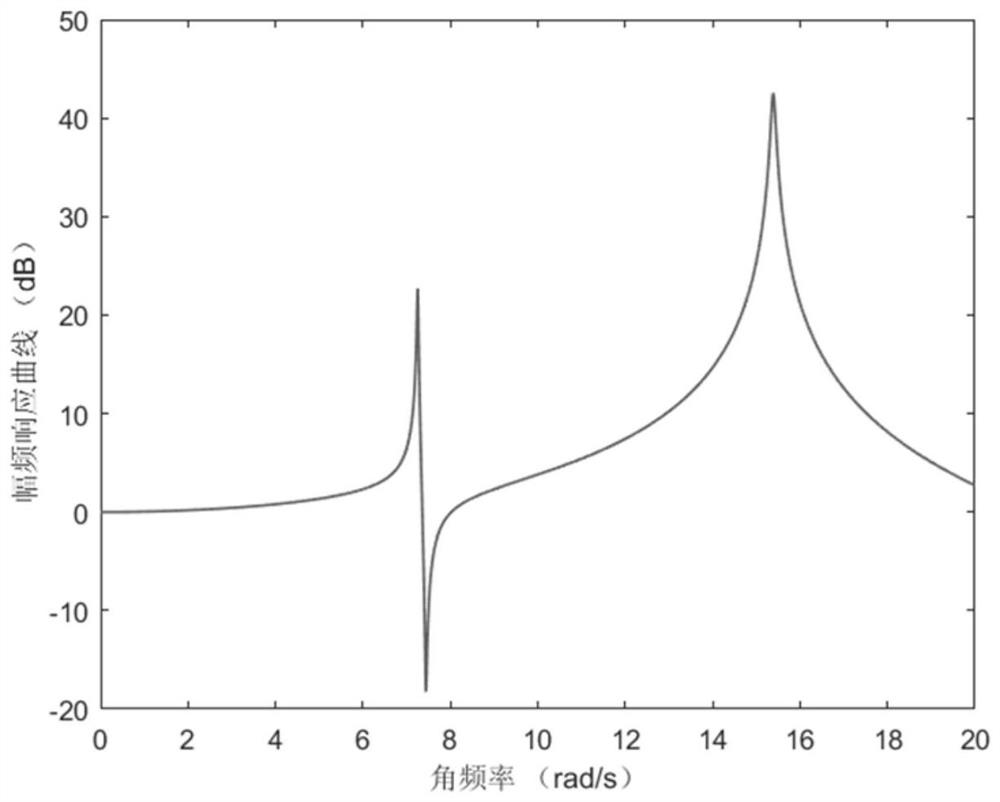

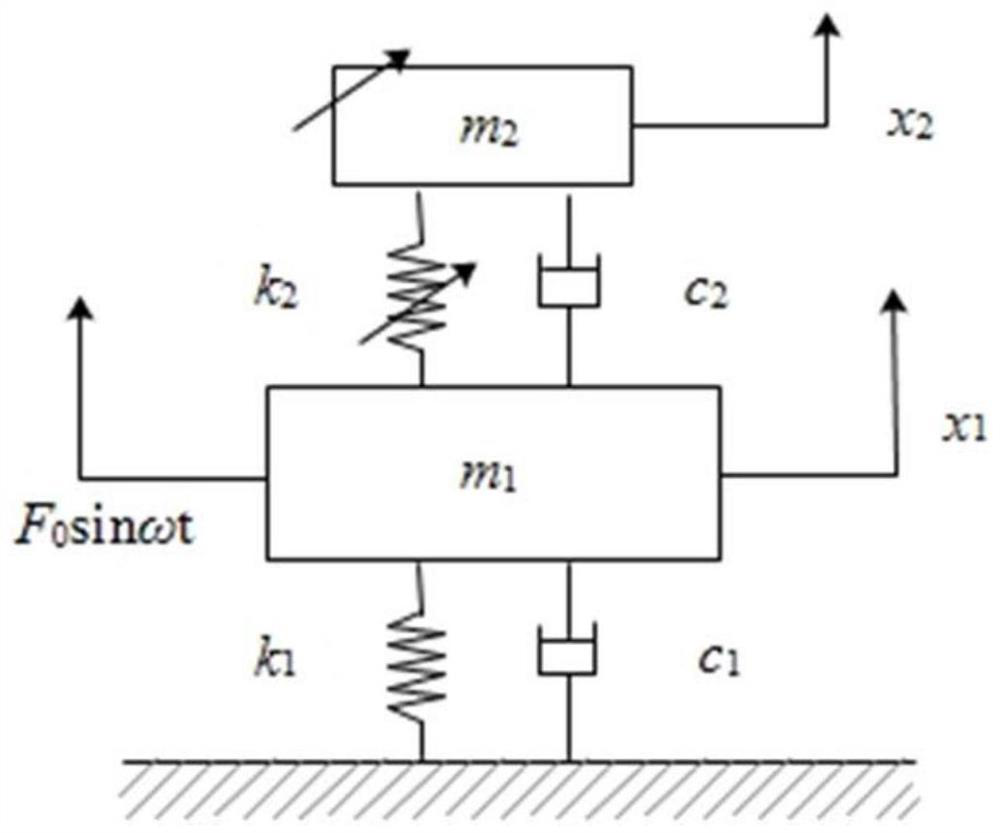

[0091] The theoretical analysis described in this application refers to: variable mass-variable stiffness compound dynamic vibration absorber model such as image 3 As shown, m 1 、k 1 、c 1 The mass, stiffness and damping of the main system respectively, m 2 、k2 、c 2 are the mass, stiffness and damping of the composite dynamic vibration absorber, F 0 sinωt is the simple harmonic excitation force on the main system. m 2 、k 2 You can change it within a certain range. According to Newton's second law, the kinetic equation can be obtained as:

[0092]

[0093] where x 1 , x 2 , The displacement and velocity of the main system and the shock absorber, respectively, are the accelerations of the main system and the shock absorber, respectively.

[0094] The steady-state amplitude of the main system and the shock absorber can be obtained by using the complex number solution:

[0095]

[0096] In the formula:

[0097] A=(k 1 -m 1 ω 2 )(k 2 -m 2 ω 2 )-(k 2 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com