A monitoring device and monitoring method for monitoring and early warning of hydraulic structures

A technology for hydraulic structures and monitoring devices, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of inability to verify monitoring results from other angles, monitoring range and low adaptability, etc., to facilitate sampling and inspection, improve safety, The effectiveness of enhanced monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

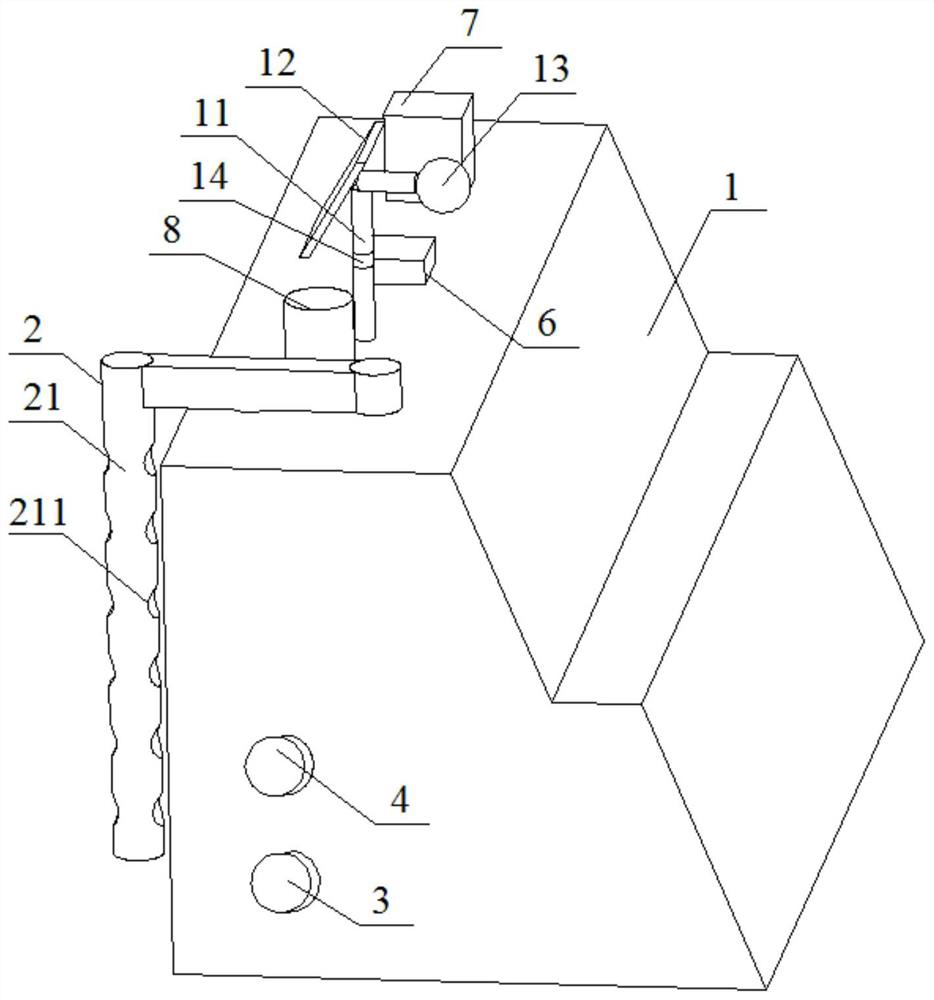

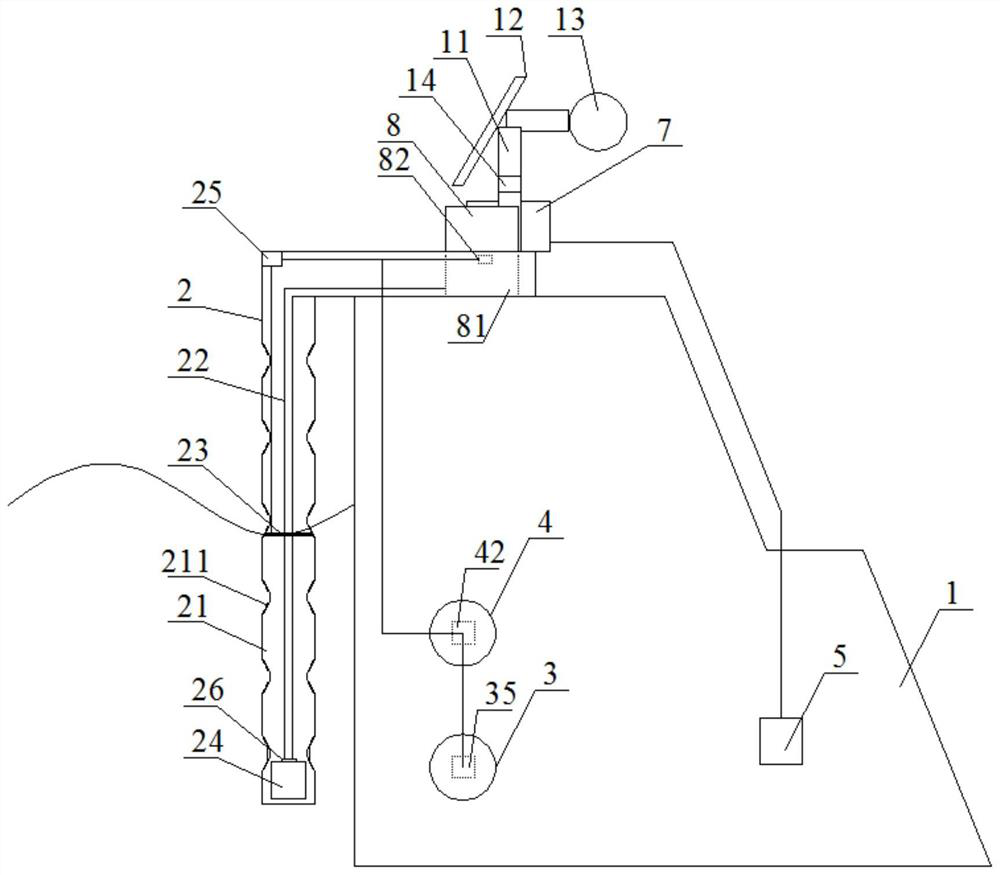

[0038] Such as figure 1 As shown, a hydraulic structure monitoring and early warning monitoring device, the hydraulic structure is a dam used for water retention or water delivery, specifically a concrete dam or an earth dam, including a hydraulic structure body 1, The upper surface of the main body 1 is provided with a pole 11, and one side of the upper end of the pole 11 is provided with a solar panel 12 for providing electric energy for each monitoring part. The solar panel 12 is a commercially available solar panel, and the other side of the upper end of the pole 11 is provided with a camera 13. The camera 13 is a commercially available AK-NH9000s high-definition camera. The pole 11 below the camera 13 is provided with an audible and visual alarm 14. The audible and visual alarm 14 is a commercially available TGSG-01T audible and visual alarm. The audible and visual alarm 14 The controller is connected to the sensors of each monitoring section.

[0039] Such as figure 2...

Embodiment 2

[0049] The present embodiment is basically the same as Embodiment 1, the difference lies in the monitoring of rainfall:

[0050] Step 4 also includes: when the rainfall monitored by the rainfall monitoring unit 8 is greater than 30 mm, the rainfall sensor 82 transmits a signal to the pressure sensor 42, so that the pressure sensor 42 reduces the value of the alarm signal triggered by the piezometer 41 from 1 MPa to 0.7 MPa At the same time, the rainfall sensor 82 transmits the signal to the temperature and humidity sensor 35, and the temperature and humidity sensor 35 transmits the signal to the controller 36, and the controller 36 controls the motor 32 to drive the temperature and humidity meter 33 to reciprocate along the transmission rod 34 to perform dynamic monitoring of temperature and humidity , Strengthen the temperature and humidity monitoring of various parts inside the hydraulic structure body.

Embodiment 3

[0052] This embodiment is basically the same as Embodiment 2, except that the positions of the temperature and humidity monitoring part 3 and the osmotic pressure monitoring part 4 are adjusted according to the length and height of the body 1:

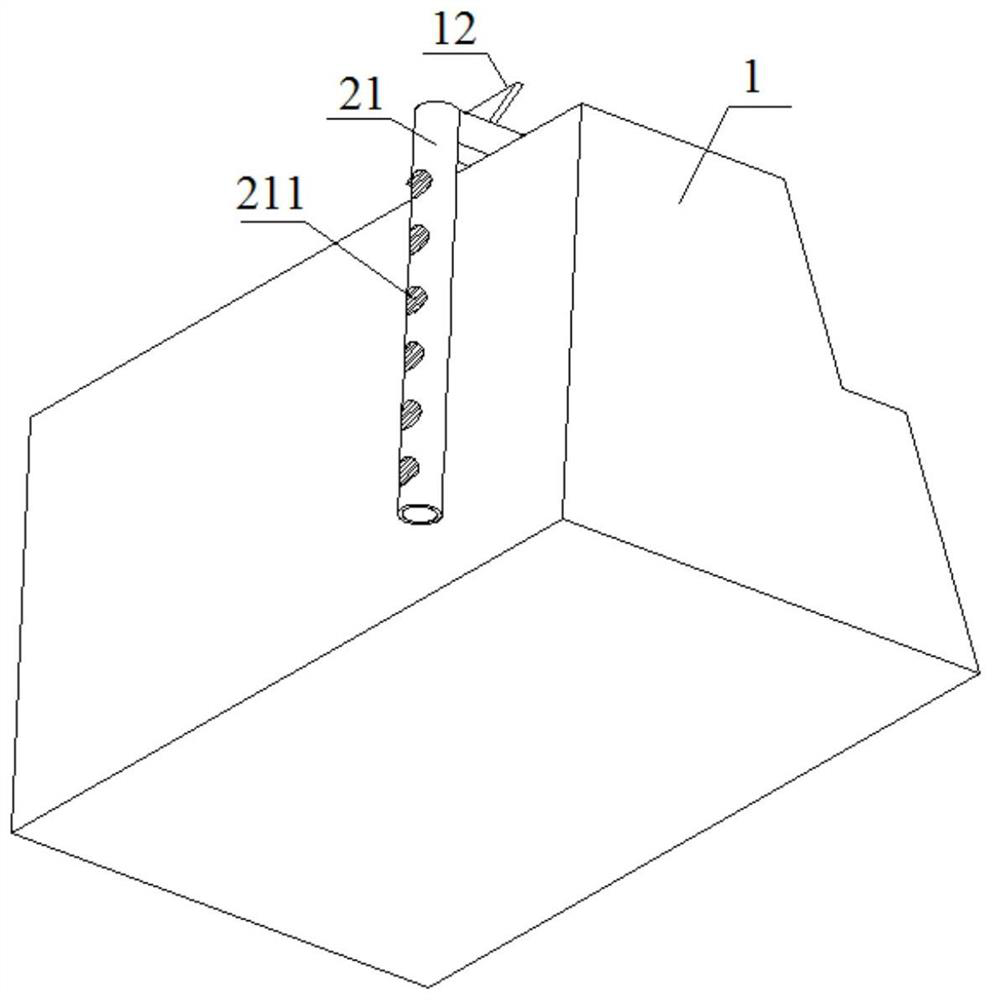

[0053] Step 1: The main body 1 of the hydraulic structure is 23.8m long and 3.4mm high, and the water level monitoring part 2 is arranged on the upstream side of the main body 1, and the drill bit is used to drill a hole 72cm from the bottom on the main body 1 side and arrange the temperature and humidity Monitoring section 3, lay out osmotic pressure monitoring section 4 at 40 cm above the temperature and humidity monitoring section 3, lower the temperature and humidity meter 33 into the temperature and humidity monitoring section 3, and arrange osmotic pressure gauges 41 on the osmotic pressure monitoring section with a group interval of 50 cm. In the part 4, the stress and strain monitoring part 5, the surface displacement monitoring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com