Hollow structure wall winding pipe double-end socket sealing structure and sealing test method

A technology of sealing structure and sealing test, which is applied in the direction of sealing surface connection, engine sealing, pipe/pipe joint/pipe fitting, etc. The sealing test method is convenient, the deformation adaptability is strong, and the effect of efficient sealing inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

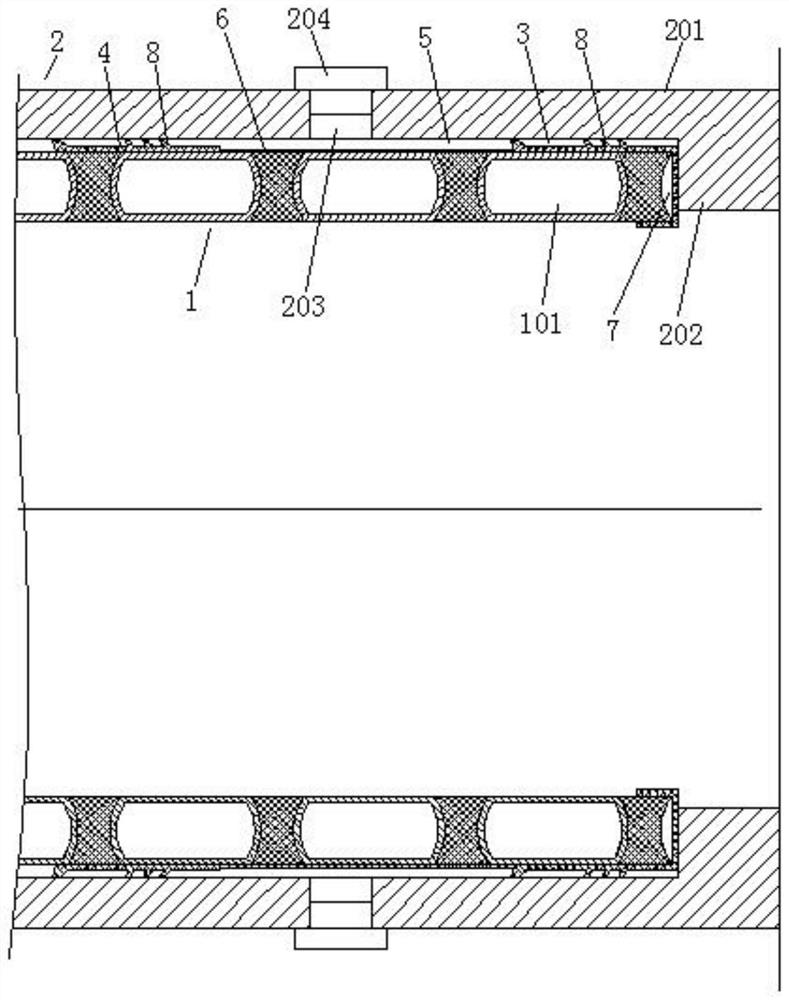

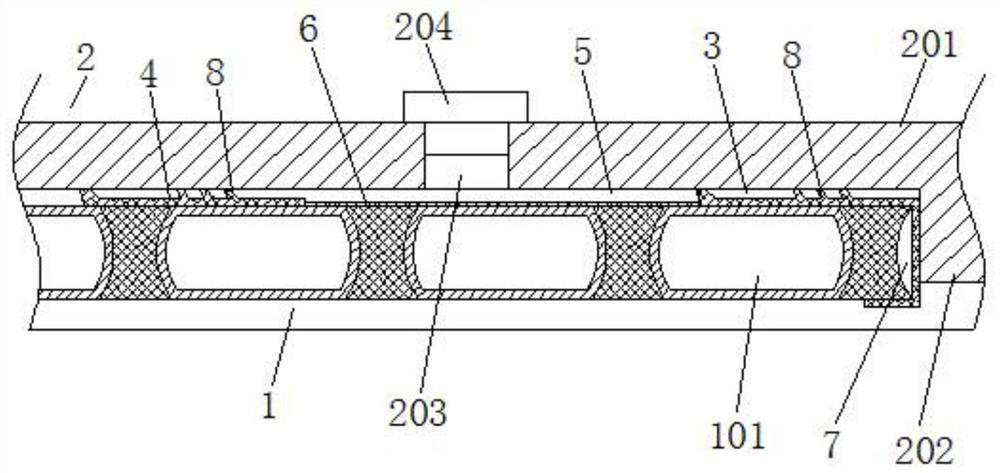

[0042] like figure 1 As shown, a double-end socket sealing structure of a hollow-wall winding pipe includes a winding pipe 1, a double-end socket joint 2 and a sealing ring. Inserted into the double-ended socket joint 2, the two ends of the double-ended socket joint 2 constitute the socket part 201, the socket part 201 is matched with the socket part 201, and the sealing connection is realized through the sealing ring, the double-ended socket joint 2 The middle part of the inner wall is provided with a partition rubber ring 202. While the partition rubber ring 202 is used to limit the distance that the socket part 101 extends into the socket part 201, the section of the pipeline can also be completely blocked by the partition rubber ring 202, so that the liquid cannot The sealing ring includes a first sealing ring 3 and a second sealing ring 4. Both the first sealing ring 3 and the second sealing ring 4 are sleeved on the socket part 101, and along the The axial direction of ...

Embodiment 2

[0052] Embodiment 2 is the same as Embodiment 1, the difference is that the outer wall of the first sealing ring 3 and / or the second sealing ring 4 is provided with a plurality of ring-shaped sealing flanges 8, and the sealing flanges The rims 8 are equidistantly arranged along the axial direction of the first sealing ring 3 or the second sealing ring 4, and the vertical surface of the sealing flange 8 is inclined toward the assembly direction of the first sealing ring 3 or the second sealing ring 4 to form a bevel, and the sealing flange The included angle between 8 and the wall surface of the first sealing ring 3 or the second sealing ring 4 is 70°-80° (specifically selected according to actual requirements). like image 3 as shown, image 3 It shows the situation that the first sealing ring 3 and the second sealing ring 4 all have three sealing flanges 8, the angle between the sealing flange 8 and the wall surface of the first sealing ring 3 or the second sealing ring 4 is...

Embodiment 3

[0054] Embodiment 3 is the same as Embodiment 2, the difference is that the double-ended socket joint 2 has a hollow structure, and the test channel 203 runs through the hollow cavity 205 of the double-ended socket joint 2 and is not connected to the hollow cavity. 205 is connected. like Figure 4 As shown, the double-ended socket joint 2 with a hollow structure is equivalent to having a double-wall structure, the inner wall of the double-ended socket joint 2 realizes sealing contact with the sealing ring and the outer wall of the end of the winding pipe 1, and the outer wall contacts the landfill , due to the existence of the hollow structure, only the outer wall of the double-ended socket joint 2 will be deformed by force during the backfilling, and the inner wall will not be deformed by force, which can ensure the integrity of the inner wall structure. At the same time, when constructing backfill, the double-ended The socket joint 2 is subjected to an external force to inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com