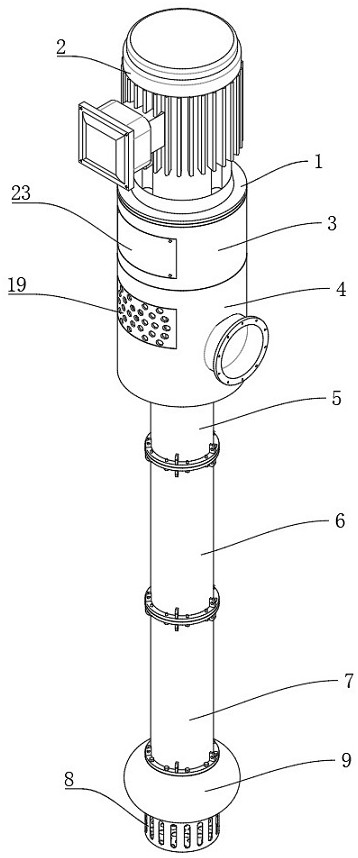

Power sealing type vertical long shaft pump

A sealed, long-shaft pump technology, used in non-variable-capacity pumps, non-displacement pumps, radial flow pumps, etc. High reliability, reduced working pressure, improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments.

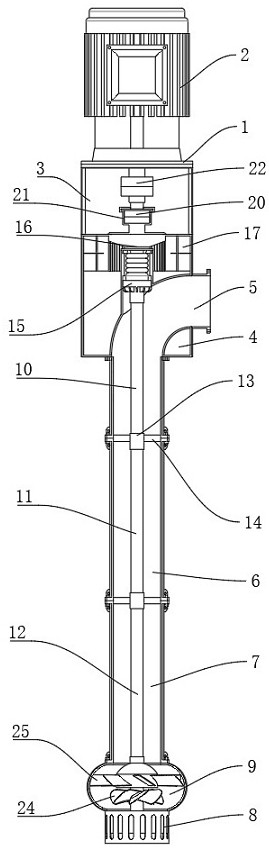

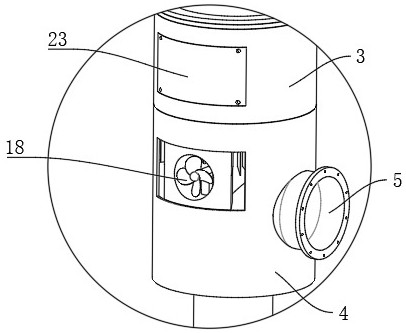

[0019]ReferFigure 1-3A power seal type vertical long-sleeve pump, including the motor holder 1, and the motor 2 is fixed to the upper side of the motor 2, and the motor holder 1 is used to fix the motor 2, the motor 2 is the same as the existing, the lower side of the motor seat 1. The matching fixation is equipped with the observation chamber 3. The observation chamber 3 functions to observe the observation, the lower side of the observation chamber 3 is fixed with a cooling chamber 4, and the cooling chamber 4 functions, and the cooling chamber 4 fixes the pump seat 5 The pump seat 5 is used to convey the liquid, and the lower end of the pump seat 5 is fixed to fix the first outer tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com