Photocatalytic ceramic, preparation method thereof and method for degrading organic dye RhB

A technology of photocatalytic ceramics and organic dyes, applied in the direction of ceramic products, chemical instruments and methods, heterogeneous catalyst chemical elements, etc., can solve the problems of less functional research on waste ceramics and no photocatalytic ceramics, and achieve raw materials The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0043] Dry and dehydrate the titanium slag, and then grind it to 325 mesh to obtain green body powder; add polyvinyl alcohol solution with a concentration of 5% to the green body powder and control the mass-volume ratio of the two to 15:1kg / L, Mix the powder and the solution to granulate, and take the granulated particles on the 40 mesh sieve under the 20 mesh sieve as the green body pellets; spread the green body pellets evenly in the mold, at 380kgf / cm 2 Press molding under a certain pressure to obtain a photocatalytic ceramic green body; put the green body into a kiln and heat it to 250°C at a heating rate of 2°C / min; then heat it to 1150°C at a heating rate of 5°C / min for sintering. And keep it at the sintering temperature for 60 minutes, cool to room temperature after the heat preservation is over, and obtain a series of photocatalytic ceramics after polishing.

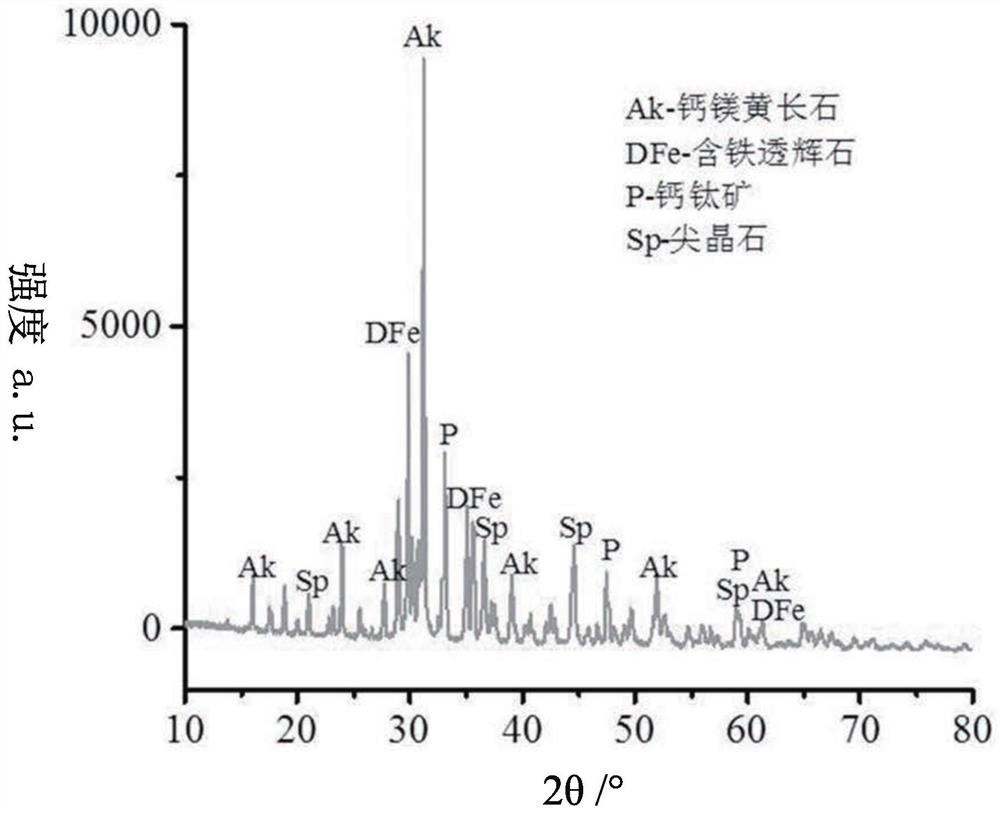

[0044] The main crystal phase of the prepared ceramic products is calcium magnesium feldspar phase, and the se...

example 2

[0046] Dry and dehydrate the titanium slag, and then grind it to 325 mesh to obtain green body powder; add polyvinyl alcohol solution with a concentration of 5% to the green body powder and control the mass-volume ratio of the two to 10:1kg / L, Mix the powder and the solution to granulate, and take the granulated particles on the 40 mesh sieve under the 20 mesh sieve as the green body pellets; spread the green body pellets evenly in the mold, at 345kgf / cm 2 Press molding under a certain pressure to obtain a photocatalytic ceramic green body; put the green body into a kiln and heat it to 250°C at a heating rate of 2°C / min to remove moisture from the green body; The heating rate of min was heated to 1180°C for sintering, and kept at the firing temperature for 60 minutes. After the heat preservation was completed, it was cooled to room temperature, and a series of photocatalytic ceramics were obtained after polishing.

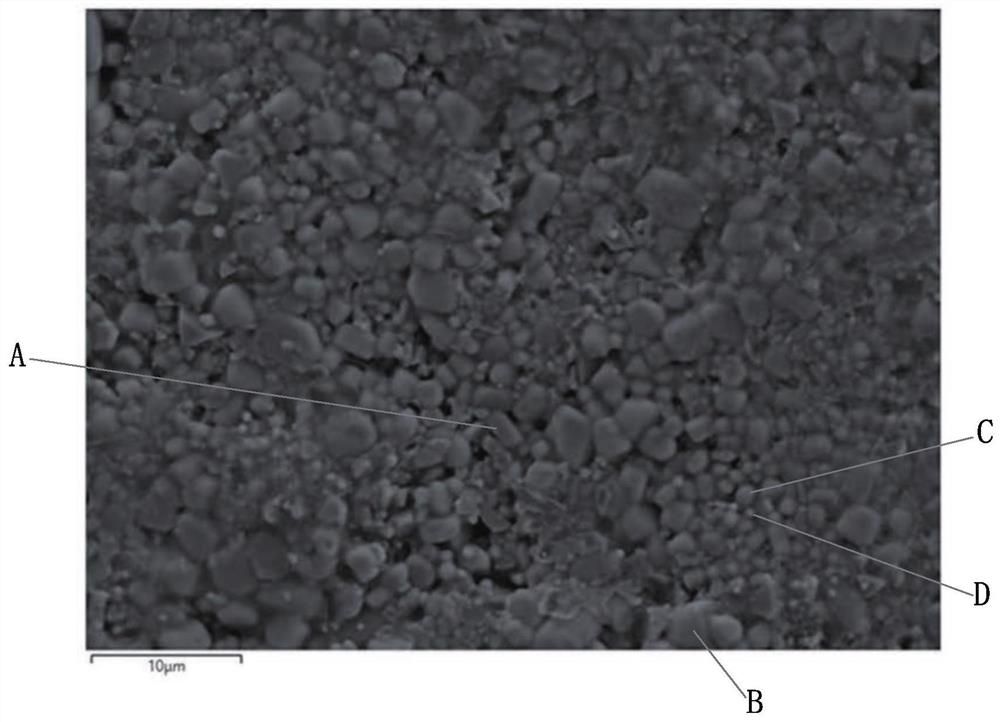

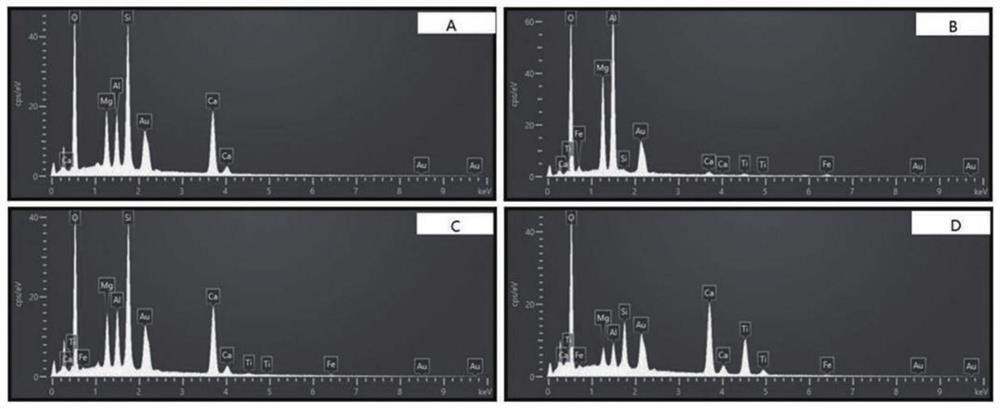

[0047] Such as figure 1 As shown, the main crystal phase of ...

example 3

[0050] Dry and dehydrate the titanium slag, and then grind it to 200 mesh to obtain green body powder; add polyvinyl alcohol solution with a concentration of 8% to the green body powder, mix the powder and the solution to granulate, and mix the mass and volume of the two The ratio is controlled to be 20:1kg / L, and the mass-to-volume ratio of the two is controlled to be 10:1kg / L; 2 Press molding under a certain pressure to obtain a photocatalytic ceramic green body; put the green body into a kiln and heat it to 200°C at a heating rate of 3°C / min; then heat it to 1200°C at a heating rate of 15°C / min for sintering. And keep it at the sintering temperature for 15 minutes, cool to room temperature after the heat preservation is over, and obtain a series of photocatalytic ceramics after polishing.

[0051] The main crystal phase of the prepared ceramic product is calcium magnesium mellow feldspar phase, and the secondary crystal phase is iron-containing diopside phase, perovskite ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com