Hydrogen peroxide disinfectant and preparation method thereof

A hydrogen peroxide, disinfectant technology, applied in the directions of disinfectants, botanical equipment and methods, biocides, etc., can solve the problems of reduced reliability, poor anti-interference ability, scarce resources, etc., to reduce potential danger, reduce Commonly used concentration, the effect of improving the bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

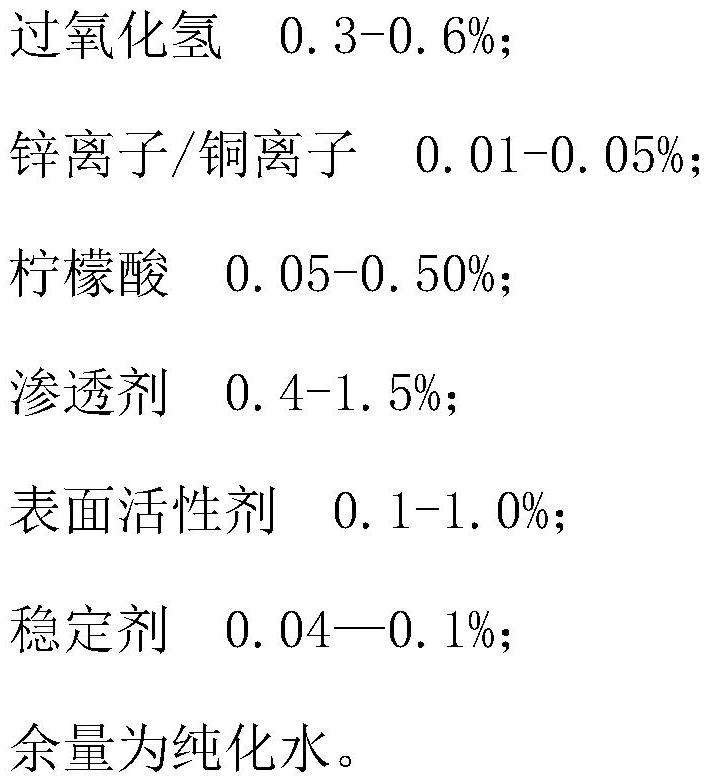

Method used

Image

Examples

Embodiment 1

[0028] In the batching container, add 98.5kg purified water, 0.08kg hydroxyethylidene diphosphonic acid, 0.1kg dodecyl dimethyl ammonium oxide, 0.5kg benzyl alcohol, 0.2kg citric acid, 0.03kg copper sulfate and 0.55kg hydrogen peroxide, and stir evenly to prepare a hydrogen peroxide disinfectant.

Embodiment 2

[0030] In the batching container, add 98.5kg of purified water, 0.1kg of diethylenetriaminepentamethylene phosphonic acid, 0.2kg of dodecylethoxy betaine, 0.5kg of benzyl alcohol, 0.2kg of citric acid, and 0.03kg of copper sulfate And 0.45kg hydrogen peroxide, stir well, make hydrogen peroxide disinfectant.

Embodiment 3

[0032] In the batching container, add 98.4kg purified water, 0.05kg hydroxyethylidene diphosphonic acid, 0.4kg octadecylethoxy betaine, 0.5kg ethylene glycol phenyl ether, 0.2kg citric acid, 0.03kg zinc sulfate And 0.37kg hydrogen peroxide, stir well, make hydrogen peroxide disinfectant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com