Device for the temperature pressure relief of a fuel tank

A technology of temperature, pressure and fuel tank, which is applied in the installation device of the container structure, the method of container discharge, the geometry/arrangement/size of the container structure, etc., can solve the problems of high cost of the vehicle, the inability to detect the combustion of the material box, etc., and achieve Effects of Safe Probing, Ensuring Design Flexibility, and Fast Response Features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Identical or similar components or elements are provided with the same reference symbols.

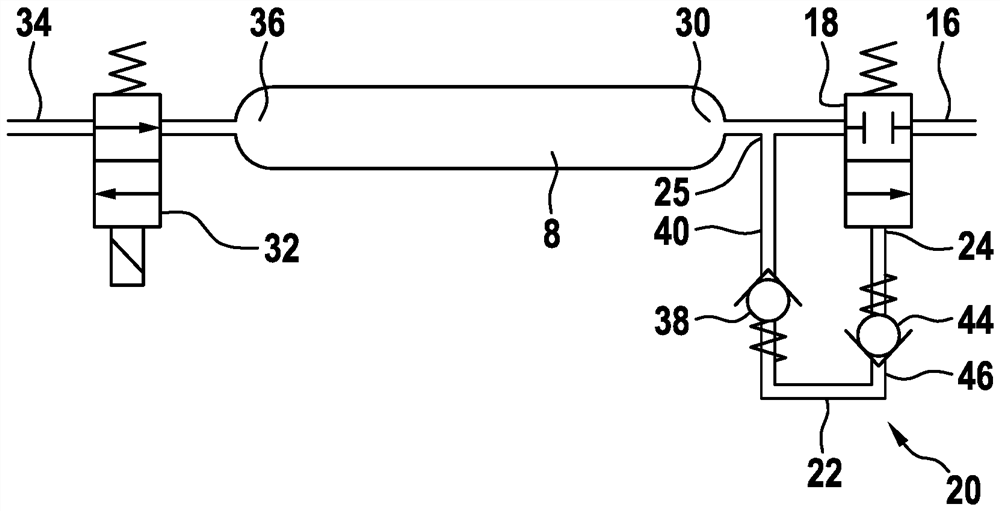

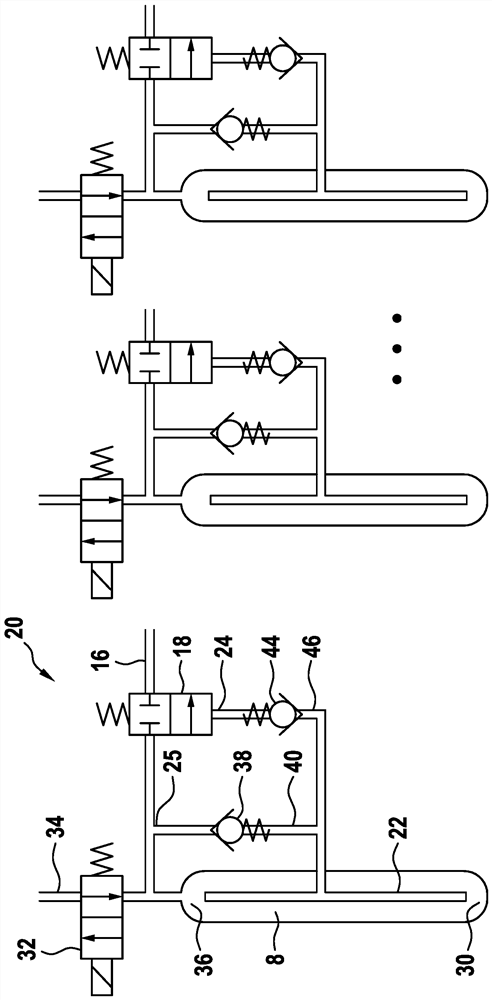

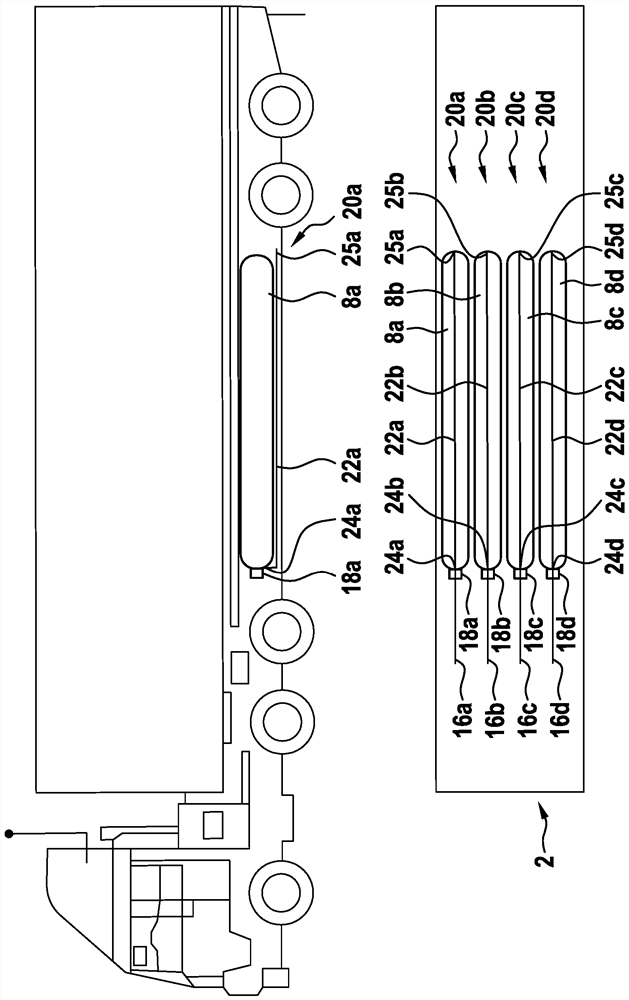

[0040] exist figure 1 A vehicle 2 is shown, which can be operated with a fuel cell system 4 . Hydrogen energy is supplied to one or more fuel cells 6 from a fuel tank 8 of the fuel cell system 4 , which is designed as a hydrogen storage tank. The fuel cell 6 generates energy, which can be used to drive the motor 12 by means of the power electronics 10 . The fuel tank 8 has a high-pressure supply line 14 and a discharge line 16 in which a pressure-controlled discharge valve 18 is arranged. In order to prevent the fuel tank 8 from bursting, for example in the event of a fire in the vicinity of the fuel tank 8 , a device 20 for temperature and pressure relief of the hydrogen storage tank 8 , shown schematically as a block, is provided.

[0041] In the device 20a-20d in the figure 2 In the first exemplary embodiment shown in side view (upper figure) and plan view from below (low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com