2D online detection method for high-precision cutter wear

A technology for tool wear and detection methods, applied in measuring devices, instruments, etc., can solve the problems of low detection accuracy, difficult detection steps, disassembly of tools or workpieces, etc., to achieve simple principles and operation steps, high-precision wear measurement, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

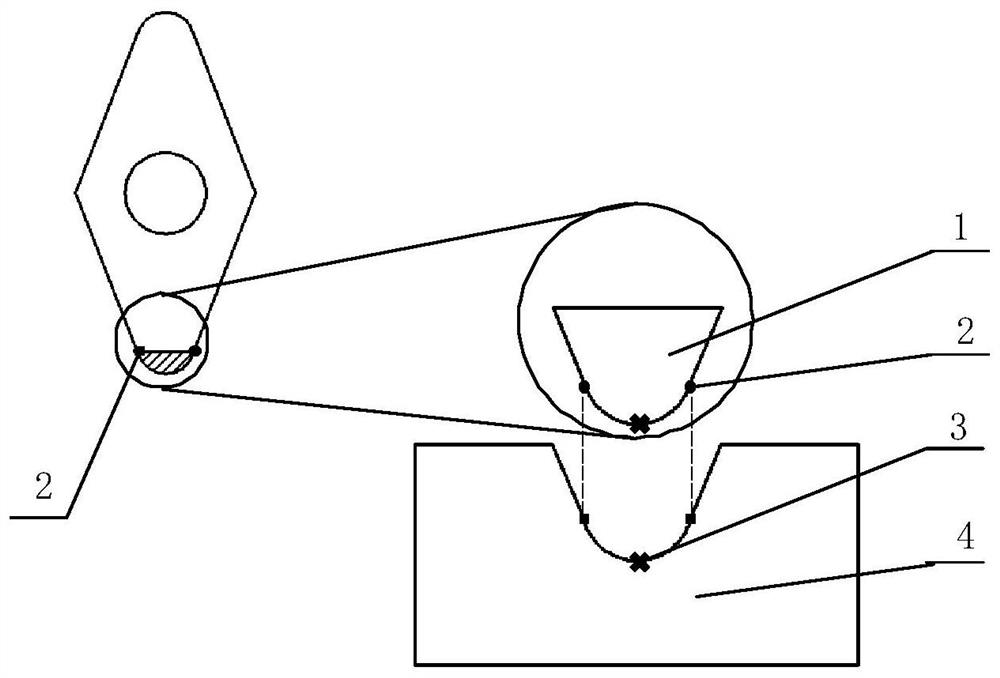

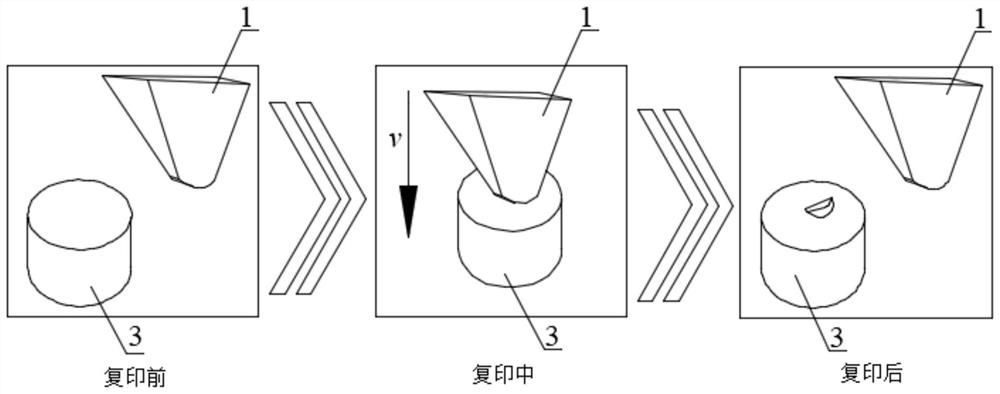

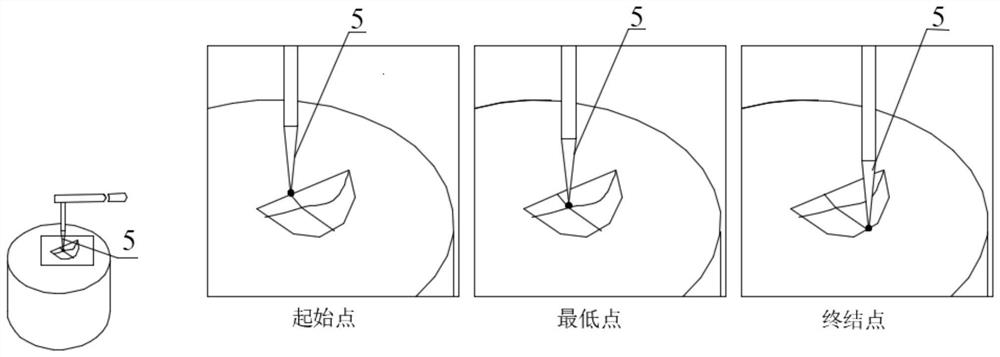

[0045] Such as Figure 1-5 As shown, the steps of the 2D detection process of tool 1 wear under the condition that the radius of the blunt circle of the tool 1 is smaller than the radius of the probe 5 of the contact profile measuring device using the method of the present invention are as follows:

[0046] A. Take two pieces of soft metal 4, grind and polish their upper and lower surfaces by mechanical polishing, after reaching a surface roughness of less than 100 nanometers and a flatness of less than several microns, clean them with deionized water, and dry them for later use.

[0047] B. Trial machining a groove with a length of 10mm with unworn tool 1, and predict the radius R of the blunt circle of tool 1 according to the surface morphology of the groove t Size, by comparison, tool 1 blunt circle radius R t Less than the radius R of the contact profilometer probe 5 p size, it is necessary to remove the influence of the radius of the probe 5 of the measuring device to ach...

Embodiment 2

[0062] Such as Figure 1-5 As shown, using the method of the present invention, the tool 1 wear 2D detection process steps under the condition that the radius of the blunt circle of the tool 1 is much larger than the radius of the probe 5 of the contact profile measuring device are as follows:

[0063] A. Take two pieces of soft metal 4, grind and polish their upper and lower surfaces by mechanical polishing, after reaching a surface roughness of less than 100 nanometers and a flatness of less than several microns, clean them with deionized water, and dry them for later use.

[0064] B. Trial machining a groove with a length of 10mm with the unworn tool 1, and predict the radius R of the blunt circle of the cutting edge according to the surface morphology of the groove t , and then with the radius size R of the probe 5 used by the contact profilometer p Comparing that, we get R t much larger than R p . Therefore, direct measurement of the dents left on the soft metal 4 bef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com