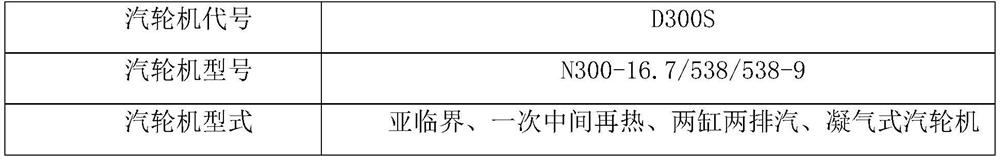

Control method of combined heat and power generation unit for cooperative steam extraction of cold section and hot section of reheater

A technology of a cogeneration unit and a control method, which is applied in the field of electric power and can solve the problems of excessive axial thrust of a steam turbine, abnormal vibration of the steam turbine, and damage to the reheating wall temperature of a boiler over temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

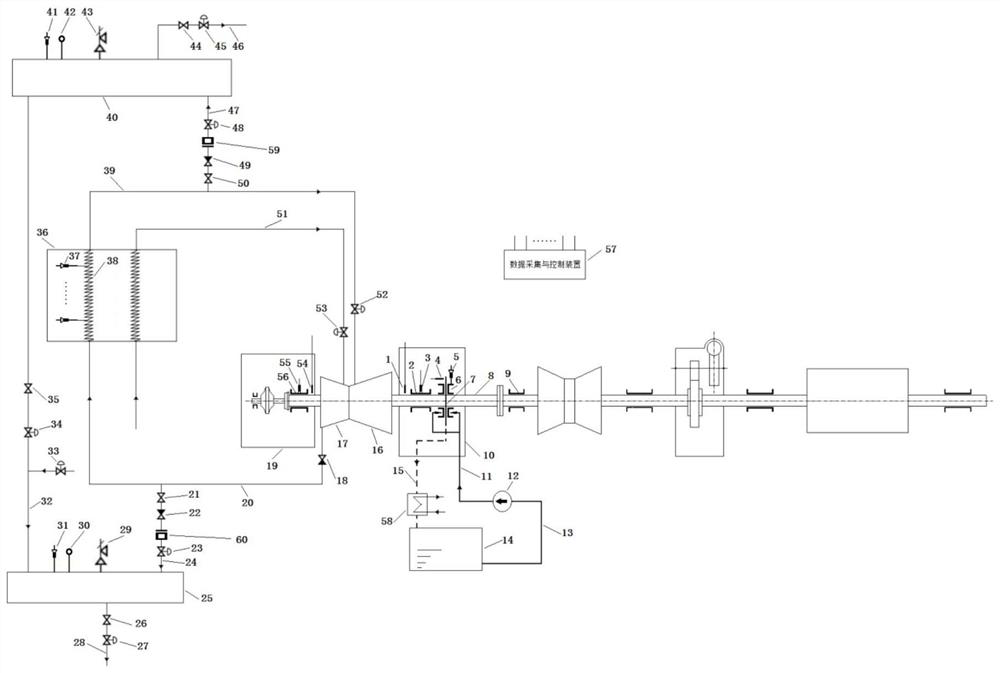

Method used

Image

Examples

Embodiment 1

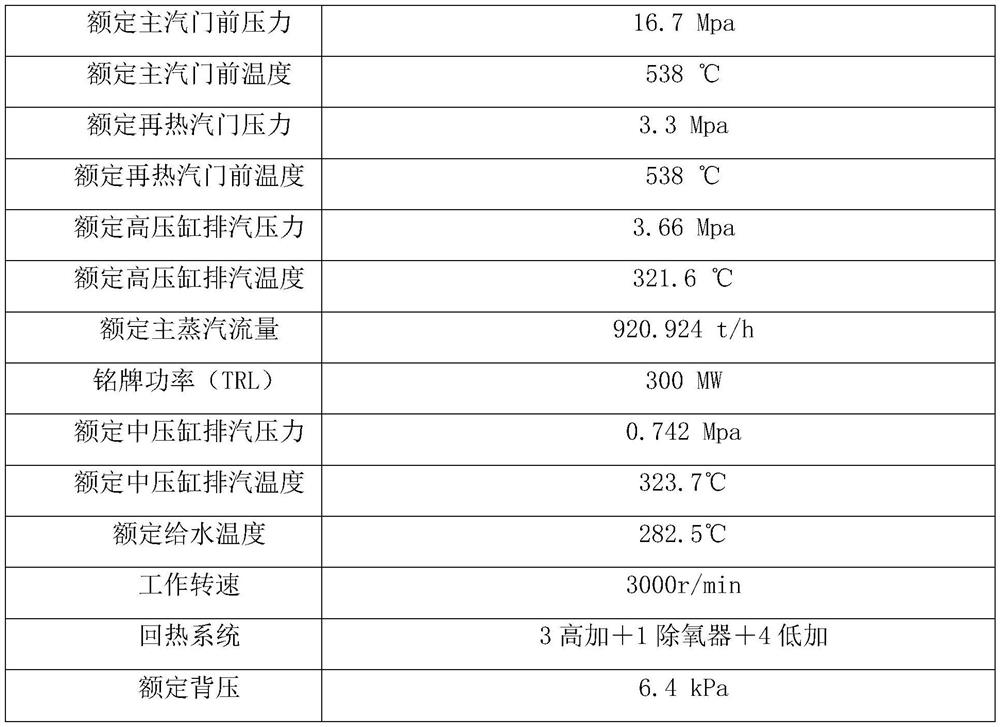

[0045] When the extraction steam flow rate from the cold section of the boiler reheater is basically similar to the extraction steam flow rate from the hot section of the boiler reheater (both are about 50t / h), as shown in working condition 1 in Table 2, the monitored parameters are all at Within the range of normal operating parameters, the unit can operate safely.

Embodiment 2

[0047] When the 100t / h heating steam flow is only extracted from the hot section of the boiler reheater, as shown in working condition 2 in Table 2, the axial displacement of the monitored parameters changes from -0.16mm to -0.56mm, which is close to Alarm value -0.63mm, there is a hidden danger in the safe operation of the unit;

Embodiment 3

[0049] When the heating steam flow rate of 100t / h is only extracted from the cold section of the reheater of the boiler, as shown in working condition 3 in Table 2, the metal temperature of the reheater tube wall in the monitored parameters changes from 535°C to 561°C , not far from the alarm value of 575°C, there is a hidden danger of overtemperature damage to the reheater tube wall;

[0050] The detailed unit operating condition monitoring data are shown in Table 2. The relevant protection values of the present invention are shown in Table 3, and alarm and shutdown protection related operations are performed according to the protection values in Table 3.

[0051] Table 2 Monitoring data table

[0052]

[0053] Table 3 Protection setting table

[0054] name unit normal value alarm value Stop value axial displacement -0.63~+1.05 -0.63 or +1.05 -0.83 or +1.25 Shaft vibration μm ≤76μm ≥125μm 200μm Bearing cover vibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com