Biaxially oriented polypropylene heat-sealing film and preparation process thereof

A technology of biaxial stretching and preparation process, which is applied in the field of biaxially stretched polypropylene heat-sealing film and its preparation process, which can solve the problems of affecting the use effect and aesthetics, poor water vapor barrier permeability, and poor wear resistance of cigarette film. , to achieve the effect of improving transparency and gloss, improving aesthetics and improving surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

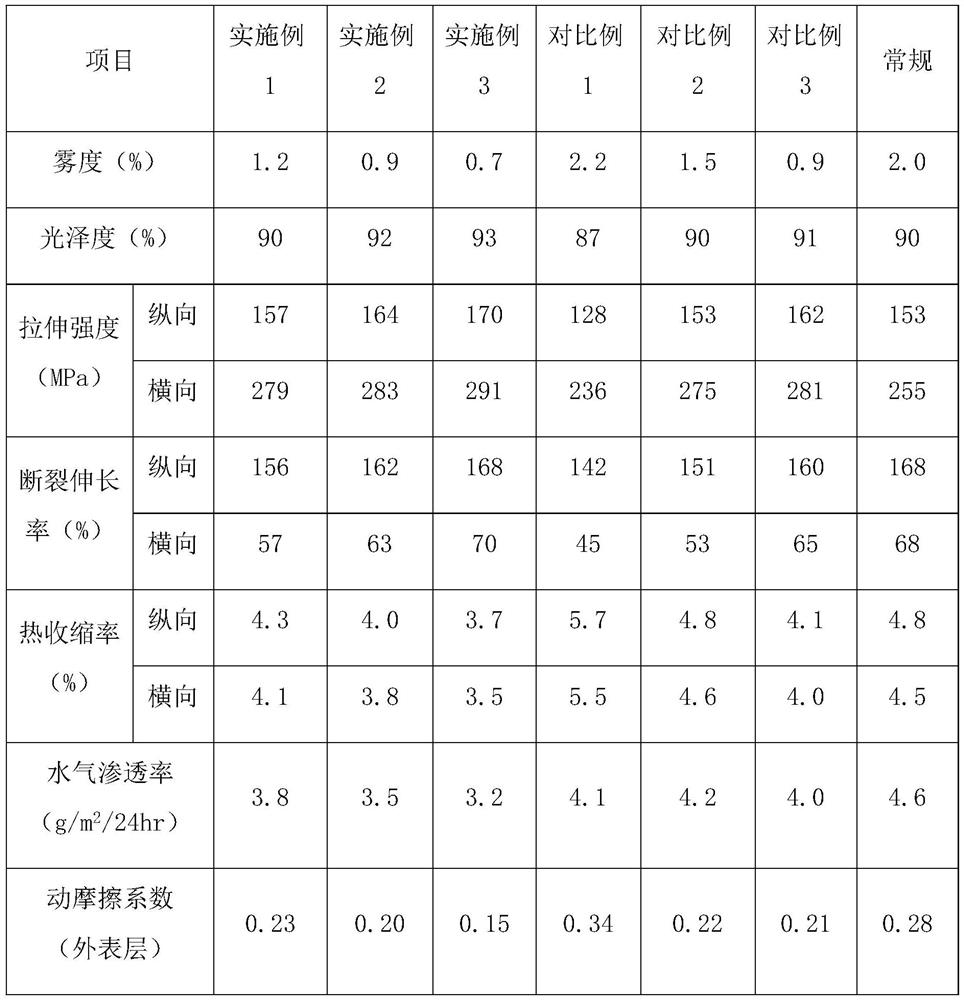

Examples

Embodiment 1

[0047] 1) Raw material preparation:

[0048] Take sodium hydroxide solution, add polysorbate-80 and vegetable oil, shear emulsification and ultrasonic treatment for 10 minutes, and obtain an emulsified solution; take 2.9 parts by weight of zinc nitrate and 7.5 parts by weight of aluminum nitrate dissolved in ethanol aqueous solution, add the emulsified solution and mix evenly, After standing still for 12 hours, washing and drying with water, zinc aluminate colloid was obtained; 18 parts by weight of ethyl orthosilicate and absolute ethanol were stirred and mixed, and hydrochloric acid aqueous solution was added to continue stirring for 1 hour, and silica gel was obtained after standing for 18 hours. ; Take 12.5 parts by weight of zinc carbonate, 7.8 parts by weight of aluminum hydroxide, 25 parts by weight of feldspar feldspar, and 0.8 parts by weight of titanium dioxide, mix and grind, sieve, mix with colloidal silica, place at a temperature of 1000 ° C for sintering, and sint...

Embodiment 2

[0057] 1) Raw material preparation:

[0058] Take sodium hydroxide solution, add polysorbate-80 and vegetable oil, shear emulsification and ultrasonic treatment for 12 minutes, and obtain an emulsified solution; take 4.5 parts by weight of zinc nitrate and 11 parts by weight of aluminum nitrate dissolved in ethanol aqueous solution, add the emulsified solution and mix evenly, After standing still for 15 hours, washing and drying with water, zinc aluminate colloid was obtained; 24 parts by weight of ethyl orthosilicate and absolute ethanol were stirred and mixed, and aqueous hydrochloric acid was added to continue stirring for 2 hours, and then stood for 21 hours to obtain silica colloid ; Take 25 parts by weight of zinc carbonate, 11 parts by weight of aluminum hydroxide, 26 parts by weight of feldspar feldspar, and 1.6 parts by weight of titanium dioxide, mix and grind, sieve, mix with colloidal silica, place at 1100 ° C for sintering, and sinter The time is 1.5h, take it out...

Embodiment 3

[0067] 1) Raw material preparation:

[0068] Add polysorbate-80 and vegetable oil to sodium hydroxide solution, shear emulsify and ultrasonically treat for 15 minutes to obtain an emulsified solution; take 6.0 parts by weight of zinc nitrate and 15.0 parts by weight of aluminum nitrate dissolved in aqueous ethanol, add the emulsified solution and mix evenly, Stand still for 18 hours, wash and dry to obtain zinc aluminate colloid; take 30 parts by weight of ethyl orthosilicate and absolute ethanol to stir and mix, add hydrochloric acid aqueous solution to continue stirring for 3 hours, and stand still for 24 hours to obtain silica colloid ; Take 37.6 parts by weight of zinc carbonate, 15 parts by weight of aluminum hydroxide, 27 parts by weight of feldspar feldspar, and 2.4 parts by weight of titanium dioxide, mix and grind them, mix them with colloidal silica after sieving, place them at a temperature of 1200°C for sintering, and sinter The time is 2 hours, take out the quick ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com