Environmental protection wastewater treatment equipment

A waste water treatment and environmental protection technology, applied in the field of environmental water treatment, can solve problems such as inability to drink normally, disturb the ecological environment, and deteriorate water quality, achieve good disinfection and sterilization effects, reduce workload, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

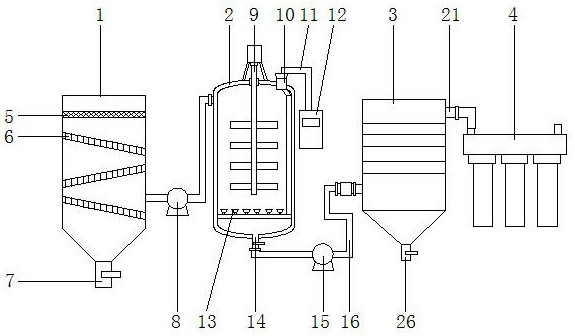

Embodiment 1

[0029] Such as Figure 1-Figure 5 As shown, the present invention provides a technical solution: an environmental protection wastewater treatment equipment, including a primary treatment tank 1, a disinfection tower 2, a filter tower 3 and a water quality purifier 4, which can sequentially complete the removal of impurities and sewage, oxidation and sterilization of wastewater, The processes of layered filtration and water purification meet the quality requirements of reused water. The top of the primary treatment tank 1 is connected with a filter screen 5, which can filter floating objects and impurities in the waste water to facilitate salvage. The bottom of the filter screen 5 is At least three grid plates 6 are provided, and the grid plates 6 are staggered and obliquely connected to the inside of the primary treatment box 1 to reduce the flow rate of waste water and facilitate the precipitation of impurities and dirt. The primary treatment box The bottom of 1 is connected ...

Embodiment 2

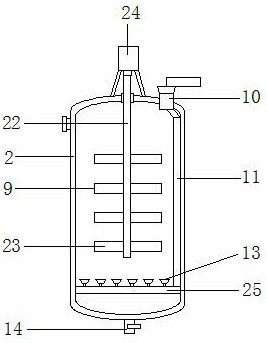

[0035] Such asfigure 1 , image 3 with Figure 5 As shown, the bottom end of the air guide pipe 11 is connected to an annular pipe 25, and the annular pipe 25 is connected to the bottom inner wall of the disinfection tower 2, and the aeration stone 13 is evenly connected to the top of the annular pipe 25, and the aeration stone 13 Aeration is performed on the incoming ozone, so that the ozone is fully dissolved in the wastewater, effectively oxidizes the wastewater, and has a good disinfection and sterilization effect.

Embodiment 3

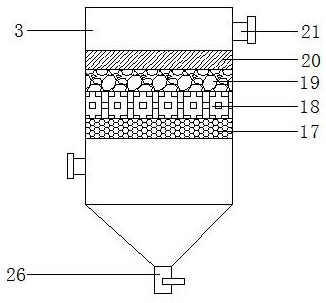

[0037] Such as figure 1 with figure 2 As shown, the bottom of the filter tower 3 is conical, and the bottom of the filter tower 3 is connected with a sewage pipe 26, which is convenient for storing filtered waste water and is discharged through the sewage pipe 26. The sewage outlet 7, the drain pipe 14 and Valves are installed on one side of the sewage pipe 26, which is convenient for sewage discharge and drainage, and is easy to operate. The top of the filter tower 3 is provided with a cavity for containing water, which is used to buffer the overflowing water after filtering. The wire mesh packing layer 17, The ceramsite filler layer 18 , the activated carbon filler layer 19 and the non-woven fabric filler layer 20 are superimposed and connected to each other, which can filter and absorb waste water, and have excellent filtration and separation effects.

[0038] The present invention is improved in that: when this kind of environmental protection wastewater treatment equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com