Method for constructing large-span deck segment of ship

A construction method and large-span technology, which can be applied to ships and other directions, can solve problems such as affecting the construction cycle of ships, many process reinforcements, and damage to the surface of the base material, achieve scientific assembly and welding technology, ensure the accuracy of the panel, and reduce welding deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] A construction method of a large-span deck section of the present invention will be described in further detail below in conjunction with the accompanying drawings, in order to understand the application process of the method of the present invention more clearly, but the protection scope of the present invention cannot be limited with this.

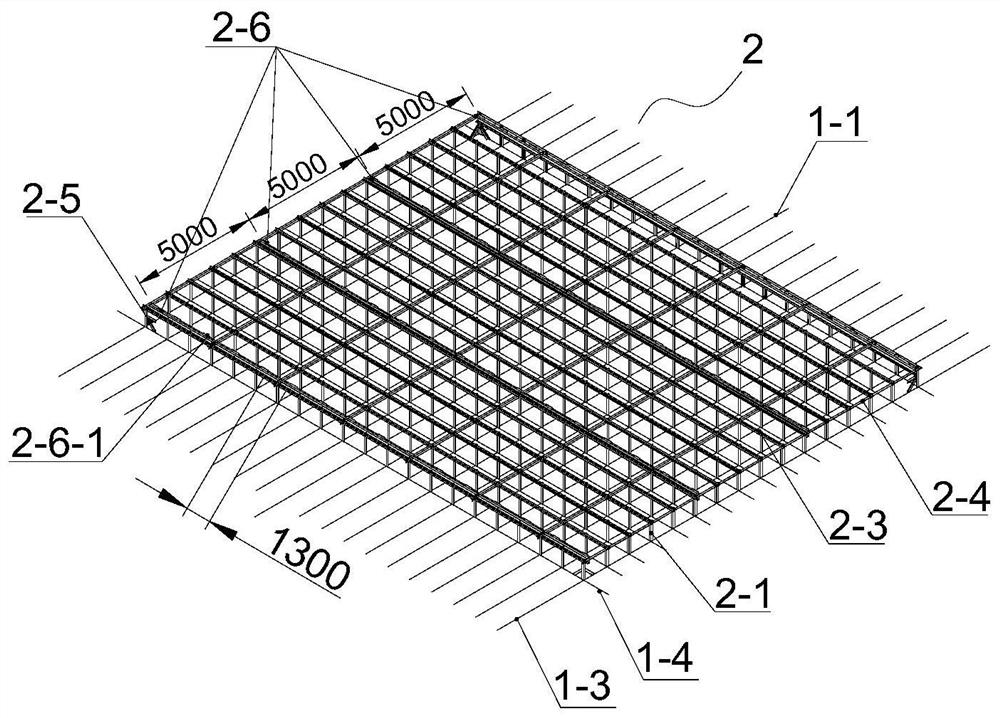

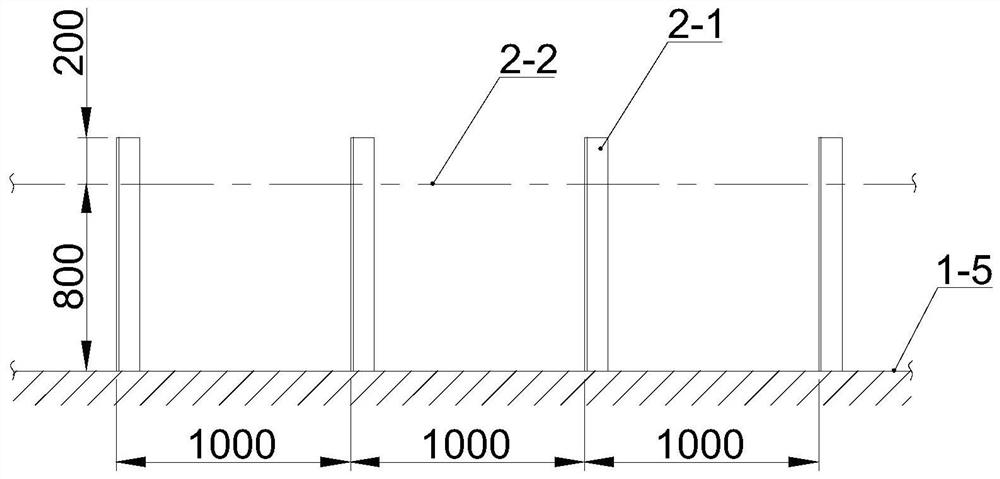

[0046] Such as Figure 1 to Figure 13 As shown, the present embodiment is a segmented construction method of a large-span deck of a ship, and the manufacturing method comprises the following steps:

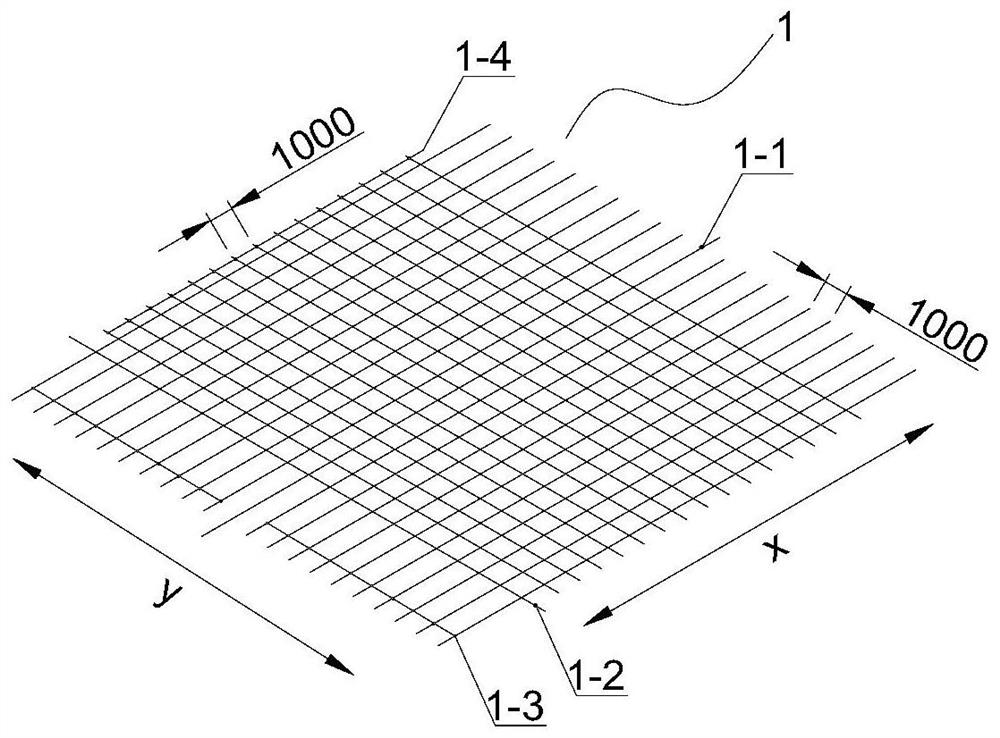

[0047] S1. Plan the tire frame ground wire, such as figure 1 As shown, use the laser theodolite to survey and delineate the subsection center ground line 1-1, take the subsection center ground line 1-1 as the positioning reference line along the x direction of the ship, and draw out according to the subsection center ground line 1-1 The square line is used as the positioning ground wire 1-2 without margin, and the perpendicularity er...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com