Automatic grinding assembly line for casting burrs

An assembly line and casting technology, which is applied in the direction of machine tools, grinding machines, and grinding feed motions suitable for grinding the edge of workpieces. It can solve problems such as high difficulty, large damage, and difficult collection, and achieve high degree of freedom and automation. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

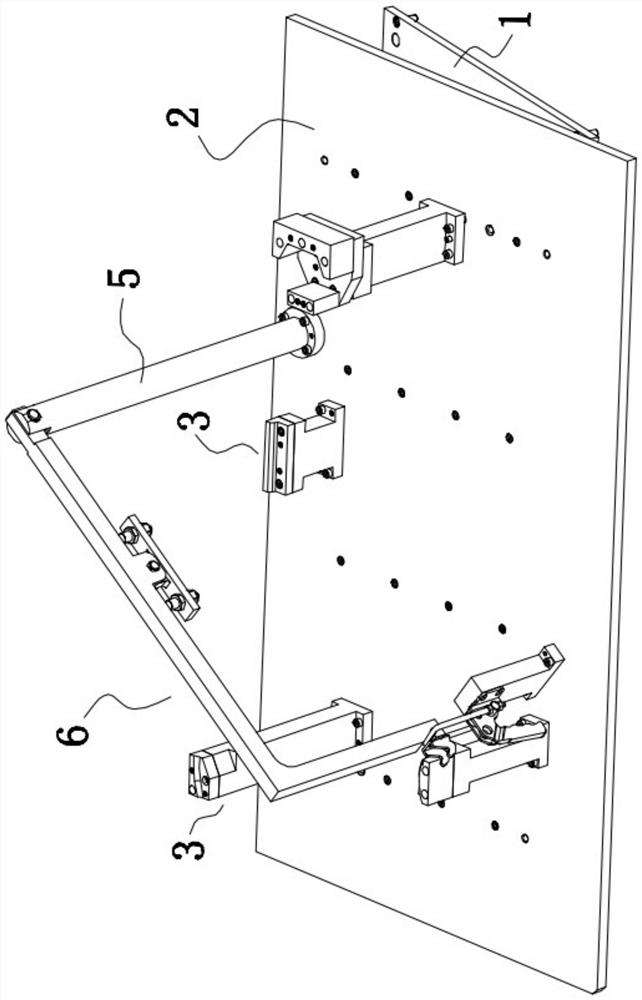

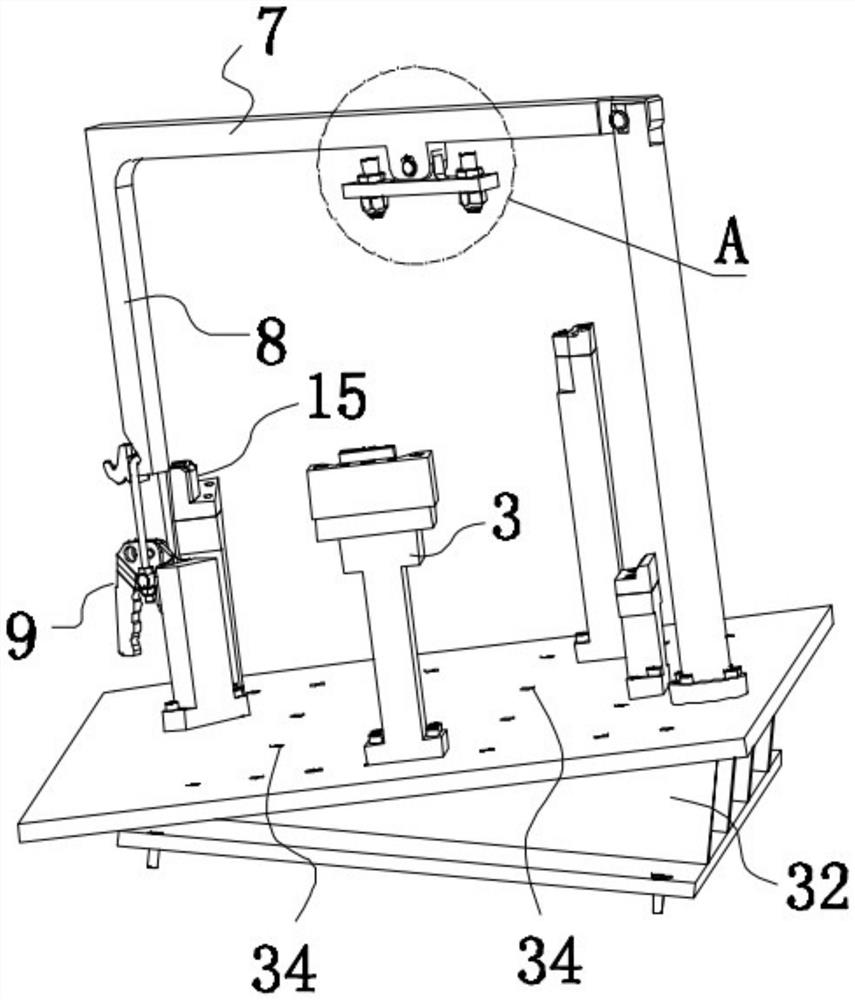

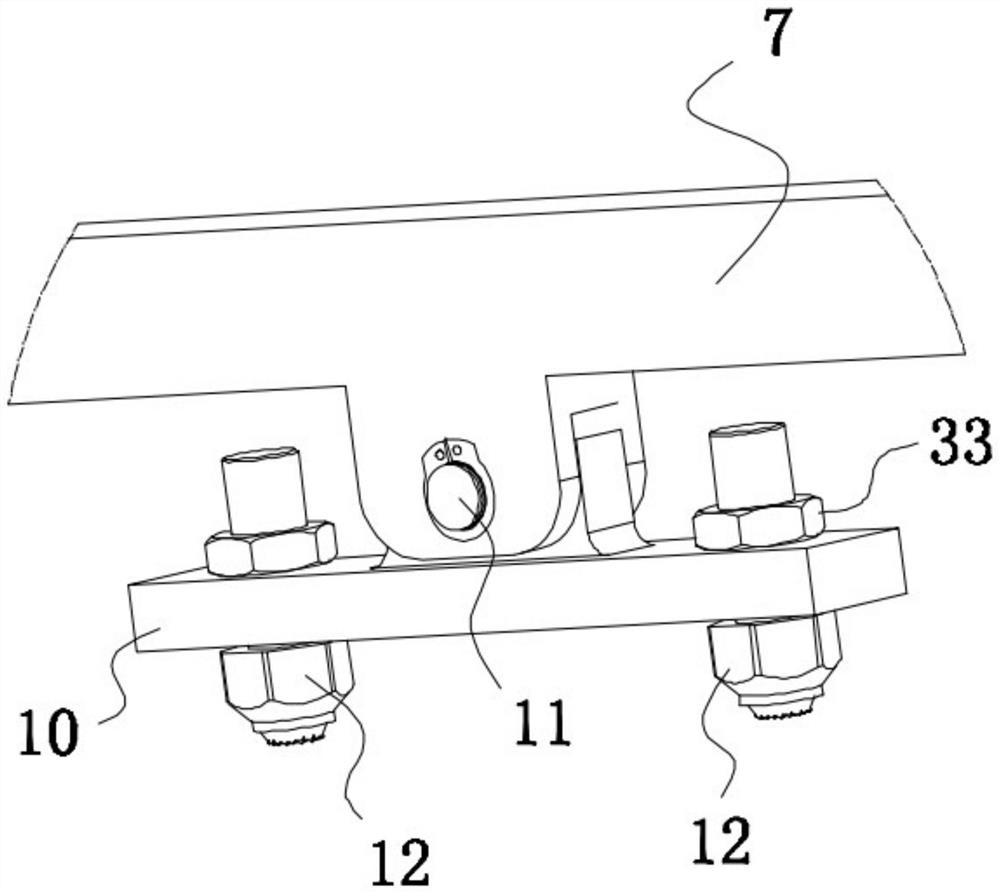

[0040] In order to achieve the purpose of the present invention, an automatic grinding assembly line for casting burrs is characterized in that it includes: jigs to limit the casting 16; the assembly line includes a casting conveyor belt 19 for carrying jigs and castings 16, and also includes parallel devices. On the scrap conveyor belt 18 on one side of the casting conveyor belt 19, the casting 16 is located on the jig; the grinding robot 17 is located on the side of the scrap conveyor belt 18 away from the casting conveyor belt 19, and the grinding robot 17 is equipped with a cutter 24 for grinding the casting 16, and a grinding robot 17 The two sides of the mirror are symmetrically provided with two casting conveyor belts 19 and two scrap conveyor belts 18; the casing 26 and the casting conveyor belt 19 are respectively composed of an inner section 44 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com