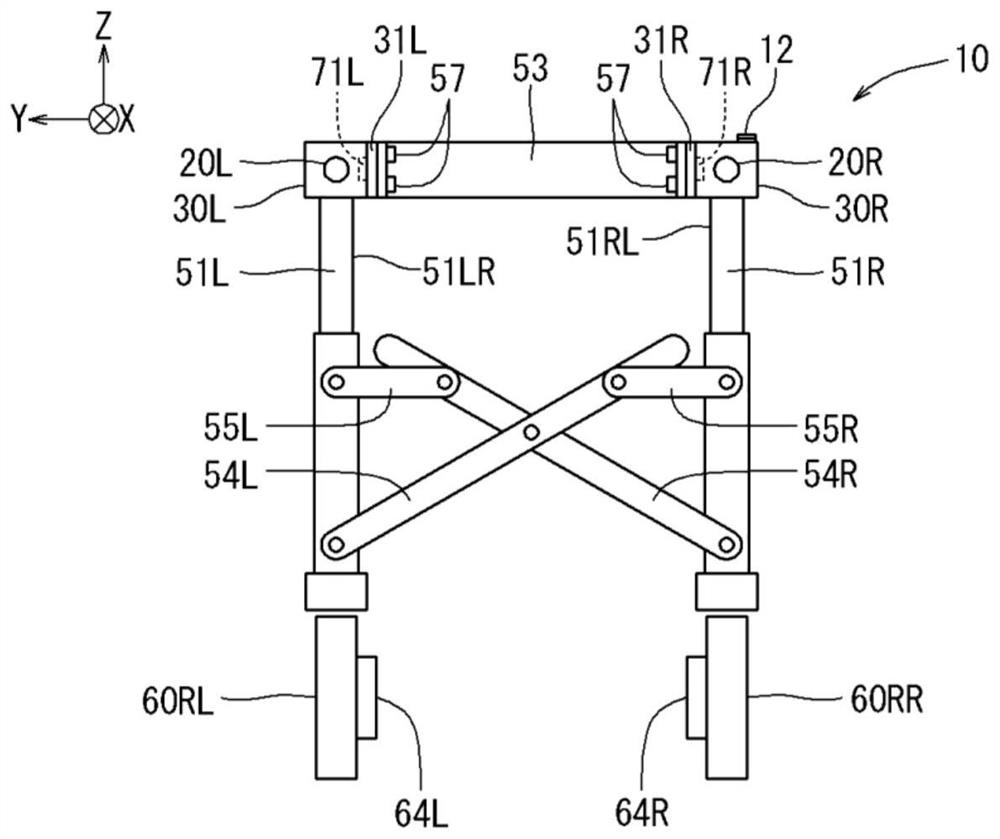

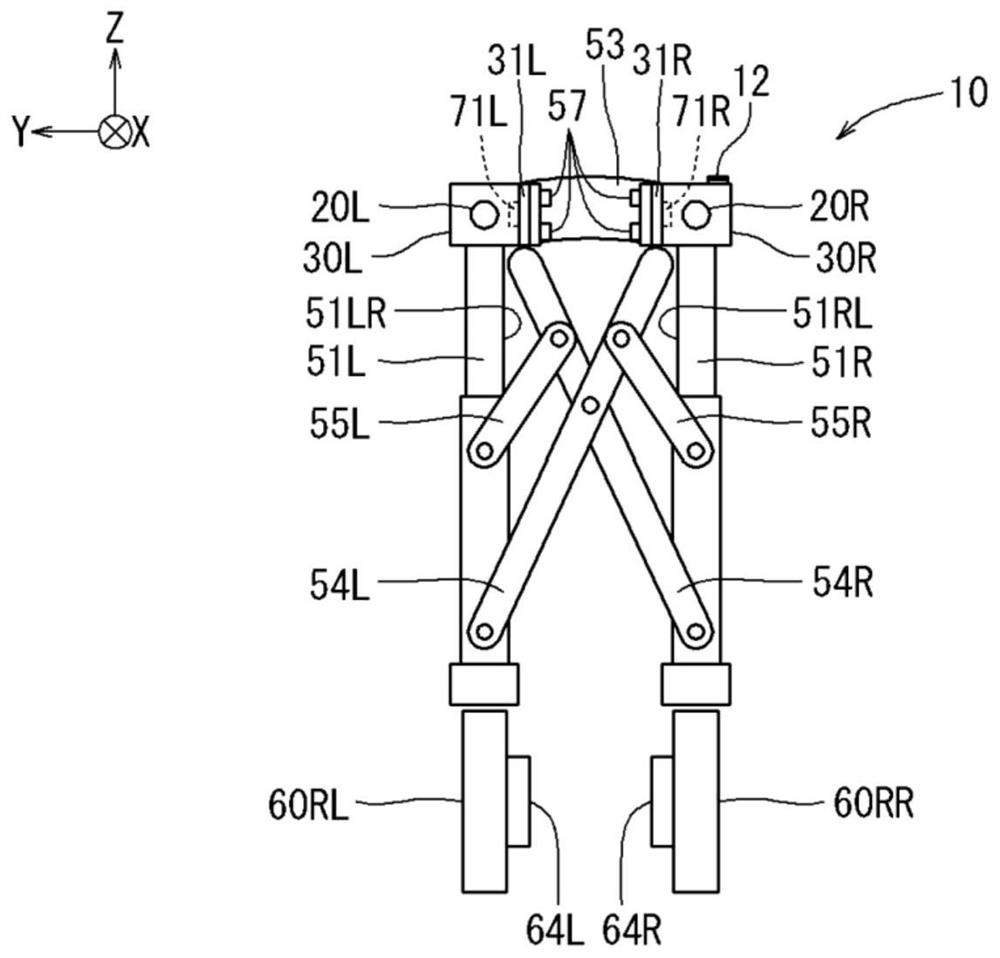

Walking assistance device

A walking aid, a pair of technology, applied in the direction of equipment to help people walk, physical therapy, etc., can solve the problems of varistor sensor failure, cumbersome repair work, etc., to achieve the effect of improving maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0111] (A) for example, such as Figure 8 As shown, a pair of shafts 35b formed from a cross-sectional circle protruding from the two end faces of the circular plate portions 35a of each of the rolling members 35 disposed on each through hole 225 disposed in the rolling members of the shaft members 22L, 22R. A cross-sectional arc-shaped leaf spring (upper body) 81 protruded from the bottom surface portion of the respective recess 225a in the center position in the axial direction (front-rear direction) of the through hole 225 is respectively formed. Further, each rolling member 35 is made upward.

[0112]Thereby, each of the rolling members 35 is biased upward by a leaf spring (upper body force member) 81, and pressing the inner peripheral surface of each sliding member 23L, 23R. As a result, it is possible to suppress loosening in the up and down direction of each slide member 23L, 23R, so that the direction of the operating force of the handle member 25L, 25R can be further reli...

no. 2 Embodiment approach

[0114] (B) Additionally, for example, a plurality of spherical rolling components are disposed in the circumferential direction of the outer peripheral surface of each of the outer circumferential surfaces of each shaft member 22L, 22R may be replaced with a roller-shaped rolling member 35. Specifically, a plurality of concave portions of the outer circumferential surface of each of the outer circumferential surfaces of the respective shaft members 22L, 22R may be formed along the axial direction, and the sphere is disposed in each recessed member as a rolling member.

[0115] Thereby, even if the user is dejected on the travel assist device 10, the body weight is applied to each of the handle members 25L, 25R, and the handle member 25L, 25R can be made in the front-rear direction, in other words, in the shaft member 22L. The axial direction of 22R is smoothly sliding. As a result, in a state where the user is applied to the travel assist device 10, the handle member can be reliab...

Embodiment approach

[0117] (C) Further, for example, it may be used instead of each of the operating direction detecting devices 71L, 71R, and Figure 9 as well as Figure 10 The respective operating direction detecting devices 91L, 91R are shown. The operating direction detecting means 91L, 91R are left and right pairs, and the handle frames 51L, 51R are configured or left, so based on Figure 9 as well as Figure 10 The operating force direction detecting device 91L on the left will be described, omitting the description of the operating force direction detecting device 91R on the right side.

[0118] Such as Figure 9 As shown, the operating force direction detecting device 911 includes a base member 92, a moving member 93, a pair of pressure sensitive sensors (moving direction detecting components) 75. The base member 92 is a substantially the same structure as the base member 72 of the above embodiment. Specifically, the base member 92 is the same as the base member 72 of the above embodiment, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com