Low-broken-slag tea fermentation production processing system

A technology of tea fermentation and processing system, which is applied in the direction of tea treatment before extraction, etc., can solve the problems of broken residues, appearance of tea leaves, affecting the appearance of tea leaves, etc., and achieve the effect of improving tea quality and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

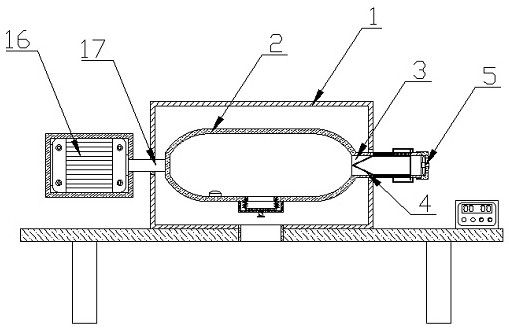

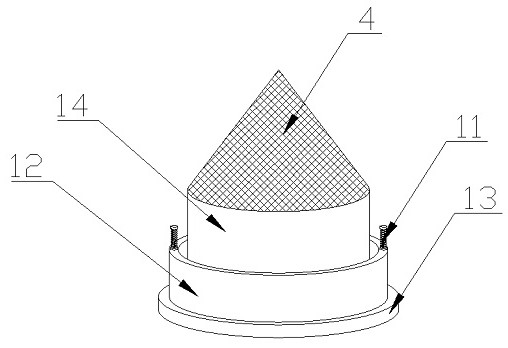

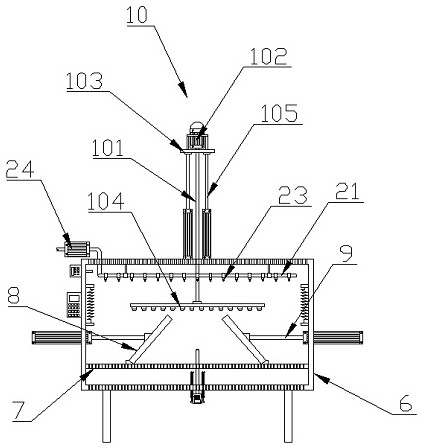

[0031] Embodiment 1: as Figures 1 to 8As shown, a low-residue tea fermentation production and processing system includes a de-greening device, a fermentation screening device and a drying device; ; The inner wall of the killing tank 2 is provided with an electric heating layer; one end of the fixing tank 2 is fixedly equipped with a feed port 3 ; The port is movably connected with a fan 5; the fermentation screening device includes a fermenter 6 and a placement plate 7 arranged inside the fermenter 6; the placement plate 7 is provided with filter holes; the placement plate 7 is slidably arranged on the surface There is a stacking plate 8; the stacking plate 8 is connected with a push rod 9; the other end of the pushing rod 9 is connected with the drive cylinder on the outer wall of the stacking plate 8; the top of the fermentation tank 6 is also provided with a bulk material mechanism 10; the drying The drying device adopts a negative pressure far-infrared drying device; in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com