Agricultural allium chinense planting pit digging equipment

A technology of scallions and digging pits, which is applied in the field of agricultural scallions planting and digging equipment, which can solve the problems of time-consuming and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

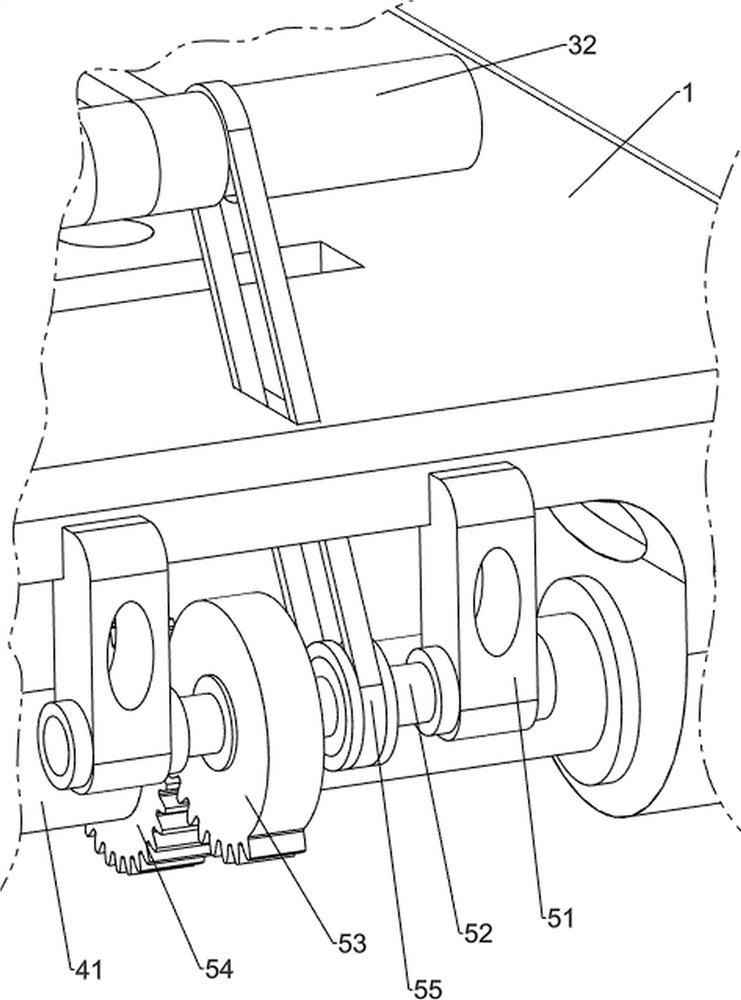

[0065] A kind of equipment for planting and digging pits with scallions for agriculture, such as figure 1 As shown, it includes workbench 1, handrail 2, punching mechanism 3 and moving mechanism 4. Handrail 2 is provided on the rear side of the top of workbench 1, and punching mechanism 3 is provided on the front side of workbench 1 top. The bottom of workbench 1 is provided with Moving mechanism 4 is arranged, and punching mechanism 3 cooperates with moving mechanism 4.

[0066] When people need to plant scallions, they can use this agricultural scallion planting and digging equipment. First, people start the hole-drilling mechanism 3, then push the handrail 2 forward, and then drive the moving mechanism 4 to rotate, and people scatter the seeds on the ground. In the hole, the effect of sowing is realized. Repeat the above operation to sow the next hole.

Embodiment 2

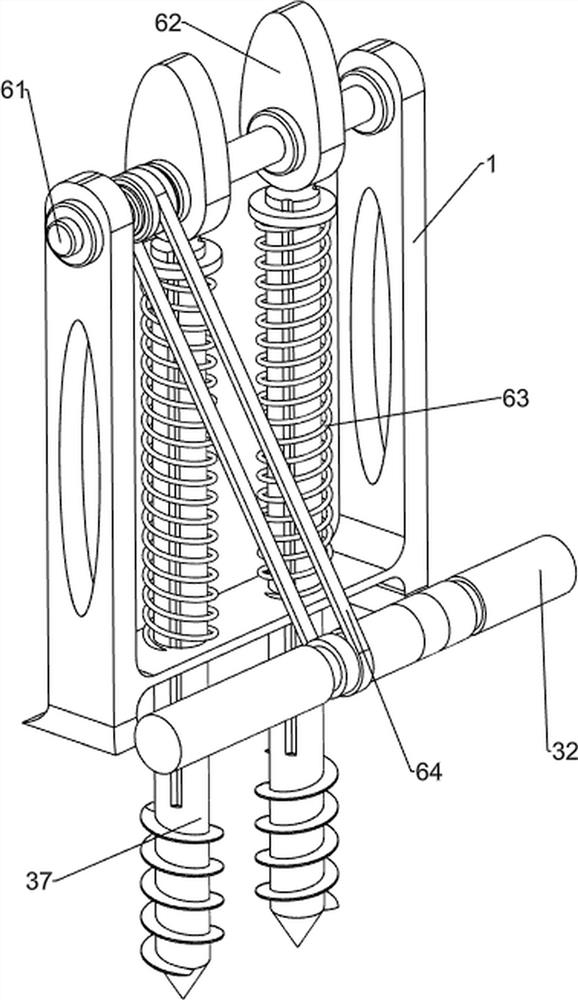

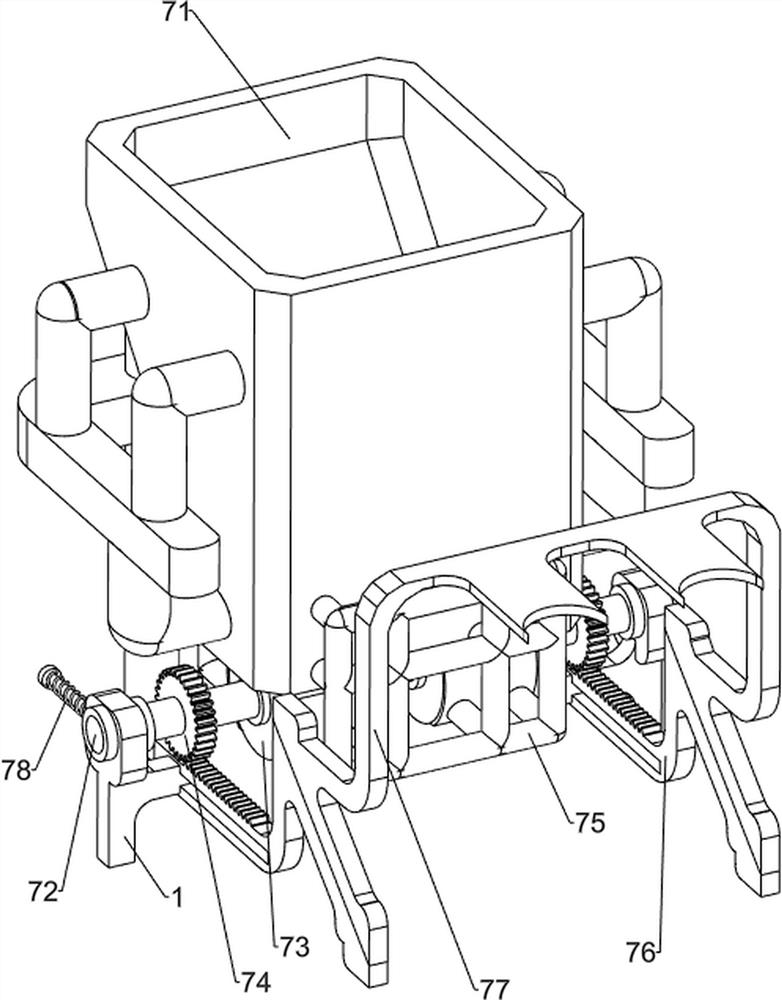

[0068] On the basis of Example 1, such as Figure 2-4As shown, the punching mechanism 3 includes a motor 31, a first transmission shaft 32, a second transmission shaft 33, a gear transmission shaft 34, a bevel gear set 35, a first pulley assembly 36, a grooved drilling rod 37 and a spur gear 38. A motor 31 is installed on the right side of the front part of the workbench 1. A first transmission shaft 32 is installed on the output shaft of the motor 31. The first transmission shaft 32 is connected to the workbench 1 in a rotational manner. The front side of the workbench 1 is rotatably equipped with a second Two transmission shafts 33, workbench 1 front side rotation type is provided with belt gear transmission shaft 34, bevel gear set 35 is connected between belt gear transmission shaft 34 and the second transmission shaft 33, the second transmission shaft 33 and the first transmission shaft The first pulley assembly 36 is connected between the 32, and the left and right sides...

Embodiment 3

[0073] On the basis of Example 2, such as Figure 5-9 As shown, an automatic forward mechanism 5 is also included, and the automatic forward mechanism 5 includes a fixed frame column 51, a third transmission shaft 52, a missing gear 53, a first full gear 54 and a second pulley assembly 55, and the left and right sides of the front of the workbench 1 Both sides are symmetrically provided with fixed frame columns 51, and a third transmission shaft 52 is arranged in a rotating manner between the two fixed frame columns 51. The left side of the third transmission shaft 52 is provided with a missing gear 53, and the right side of the third transmission shaft 52 is connected to the third transmission shaft. A second pulley assembly 55 is connected between the two drive shafts 33, and the second pulley assembly 55 passes through the workbench 1. The front rotating shaft 41 is provided with a first full gear 54, which meshes with the missing gear 53.

[0074] The first transmission sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com