Thin-film resistance strain pressure sensor and layout optimization method thereof

A technology of pressure sensor and thin film resistance, which is applied in the field of thin film resistance strain pressure sensing, can solve the problems of anti-static discharge and surge current difference, unreasonable resistance wire routing, poor electromagnetic compatibility of sensor chips, etc., to achieve anti-static Strong surge capability and good dynamic signal perception ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

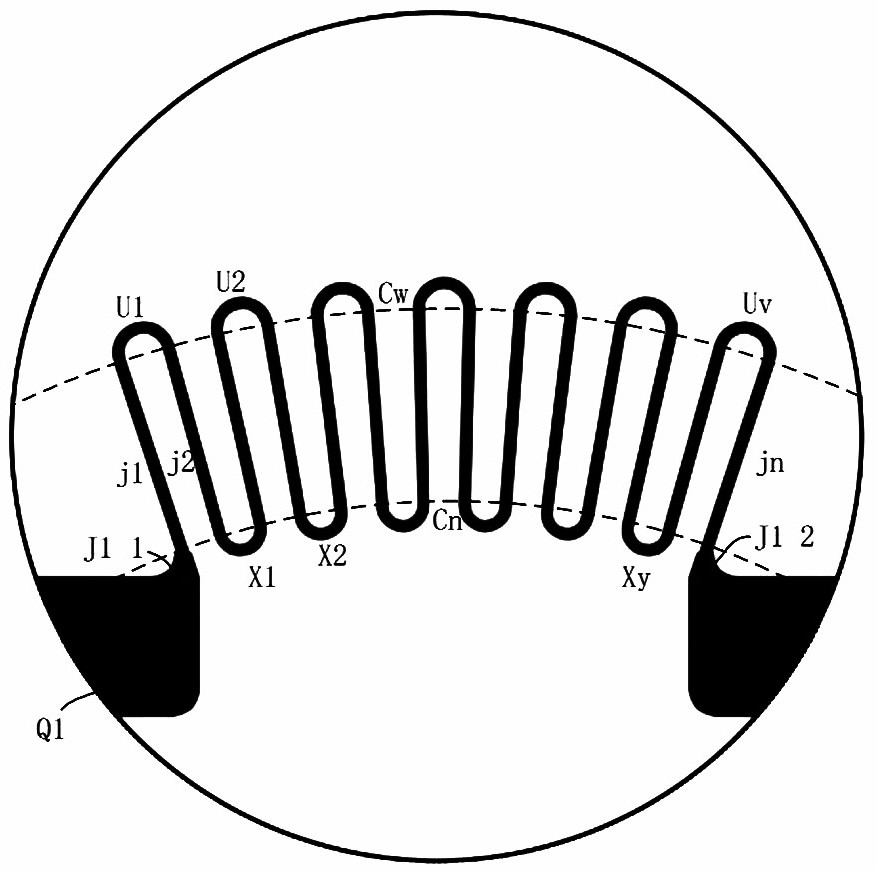

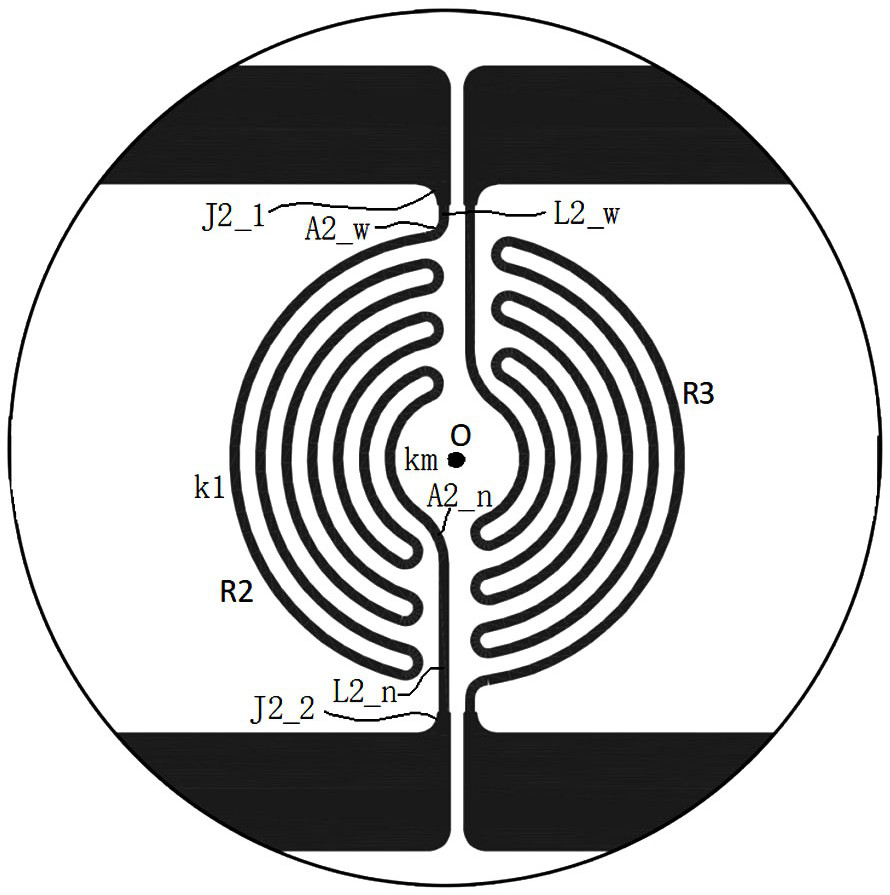

[0037] The technical problems to be solved by the present invention are: firstly, the strain magnitude and direction of each position in the sensitive deformation area on the pressure sensor chip will change, and the simple straight line and corner connection will cause the sensitivity of the sensor to fail to meet the design requirements. Problems such as poor surge capability and poor dynamic signal perception capability are solved by the present invention through reasonable layout design; the second is that the sensor chip layout is different from ordinary digital chip or digital circuit layout, and there are some irregular areas and transition connections How to accurately calculate the equivalent resistance of these components is also a technical problem to be solved by the present invention.

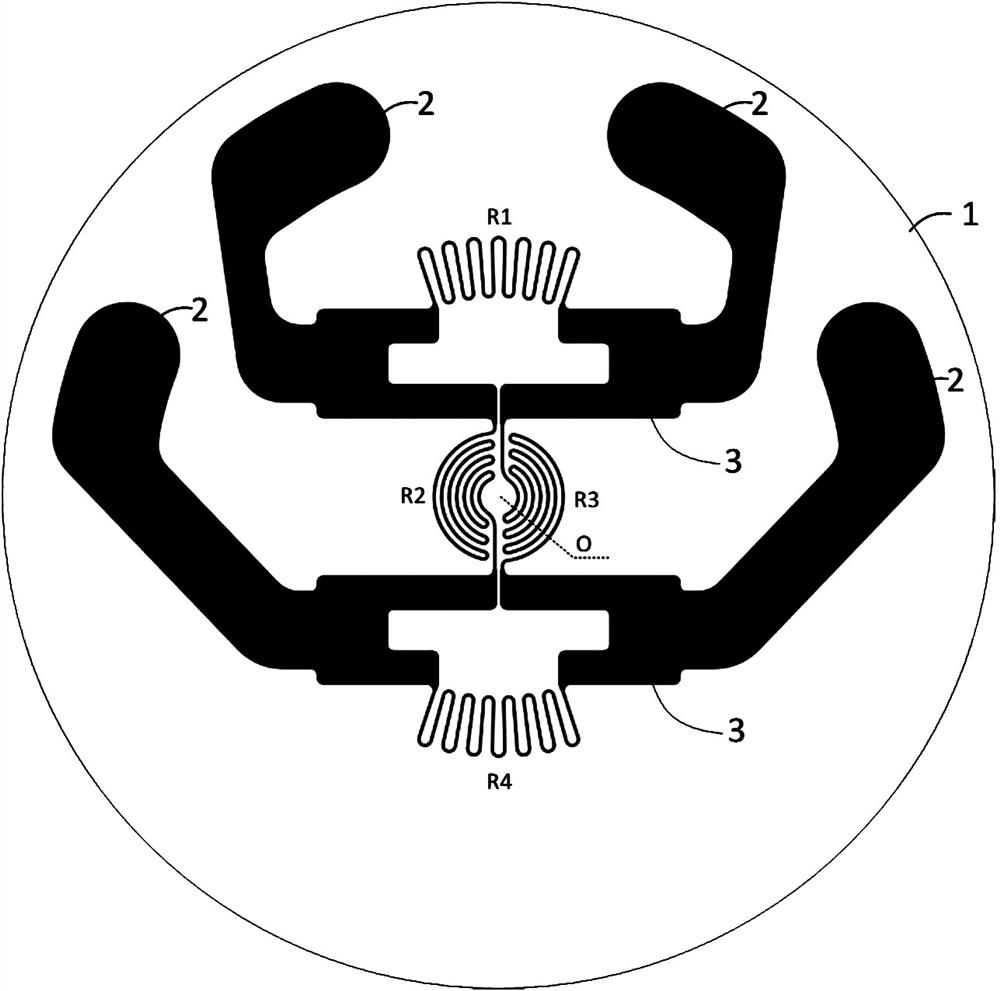

[0038] Such as figure 1 As shown, the thin-film resistive strain pressure sensor of this embodiment includes a flat diaphragm 1 and a film-shaped sensitive circuit arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com