Variable amplitude control method, device and system for vibratory roller, and vibratory roller

A vibratory road roller and amplitude control technology, applied in the field of road rollers, can solve the problems of complex structure of road roller vibrating wheels, reduced reliability of road rollers, inconvenient manufacturing and processing, etc., and achieve the effect of simple structure, realization of amplitude, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

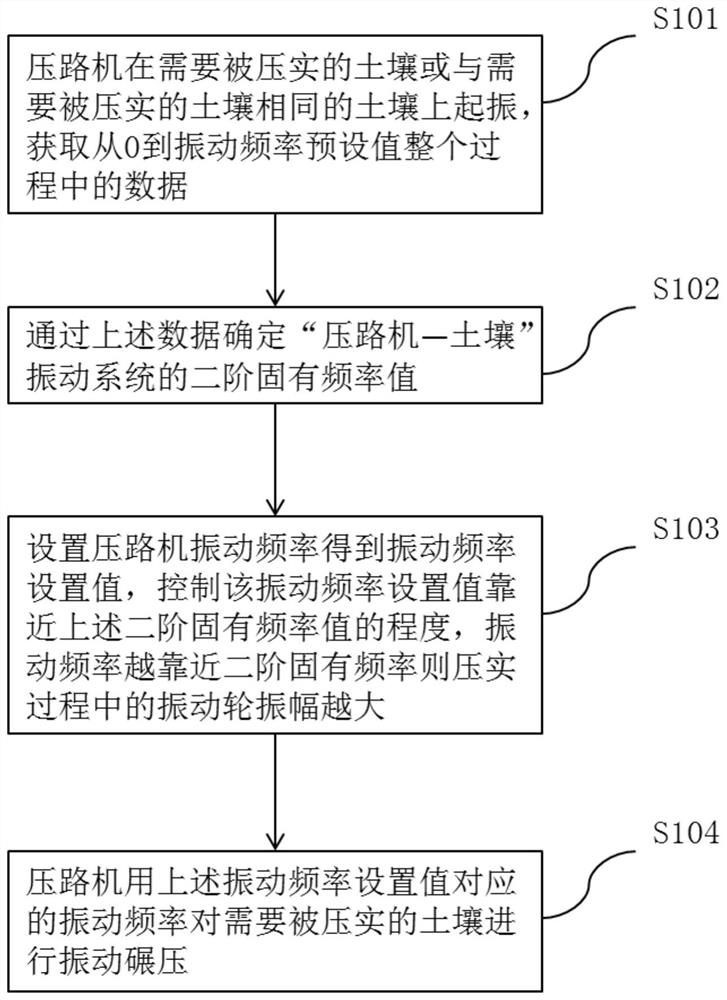

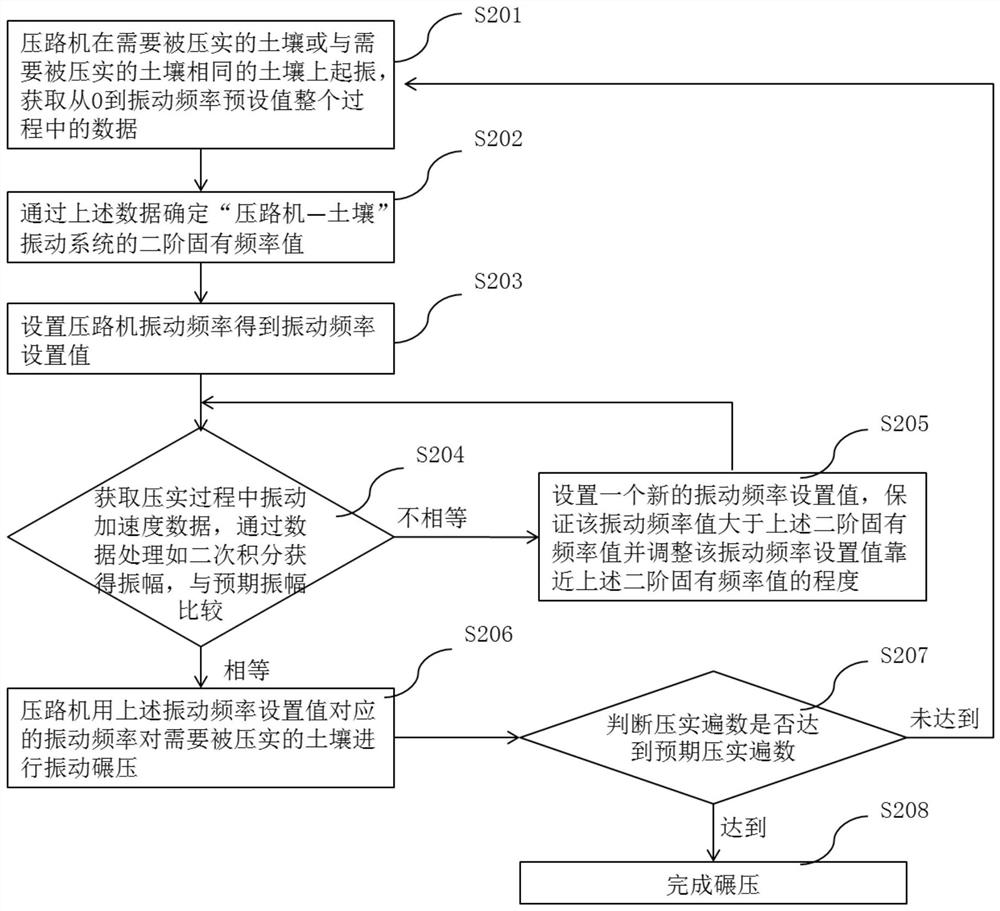

[0054] refer to figure 1 , figure 1 It is a flow chart of a vibratory roller variable amplitude control method according to an embodiment of the present invention, including the following steps:

[0055] Step S101: The road roller starts to vibrate on the soil to be compacted or the same soil as the soil to be compacted, and acquires data during the whole process from the vibration frequency from zero to the vibration frequency preset value.

[0056] The vibratory roller is a kind of construction machinery that generates centrifugal force through the high-speed rotation of the exciter assembled inside the vibrating wheel, so that the part inside the shock absorber generates continuous mechanical vibration, forcing the working medium to vibrate to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com