Amplitude-changing sine vibration and suction mechanism

A technology of sinusoidal vibration and adsorption mechanism, which is applied in the direction of motor vehicles, transportation and packaging, etc., to achieve the effect of ensuring accuracy and improving controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below in conjunction with the accompanying drawings.

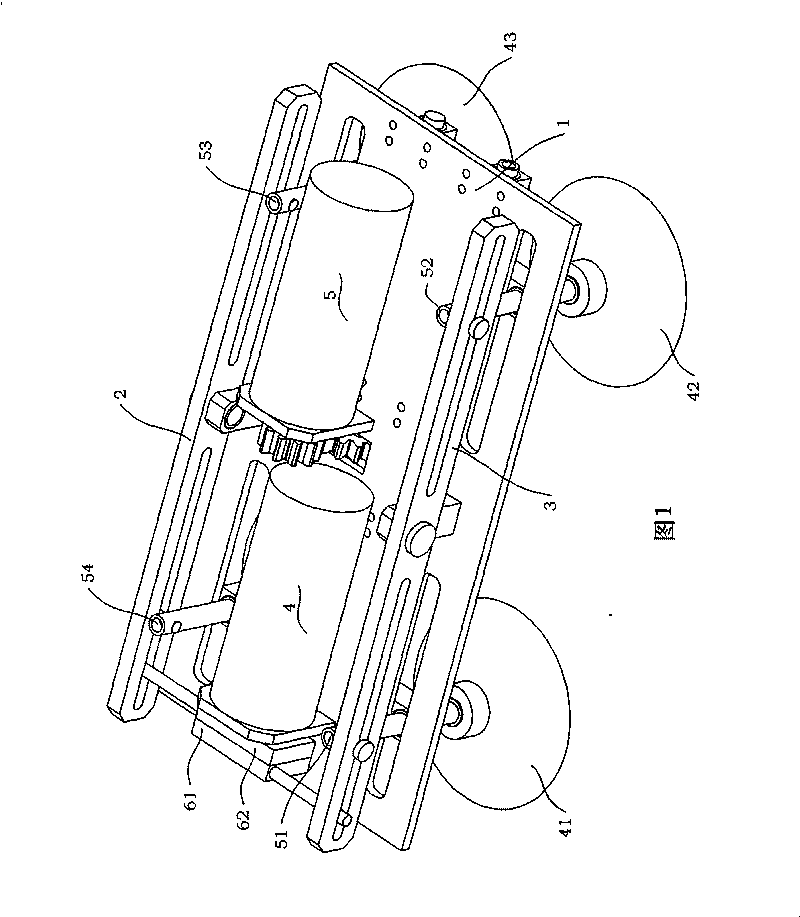

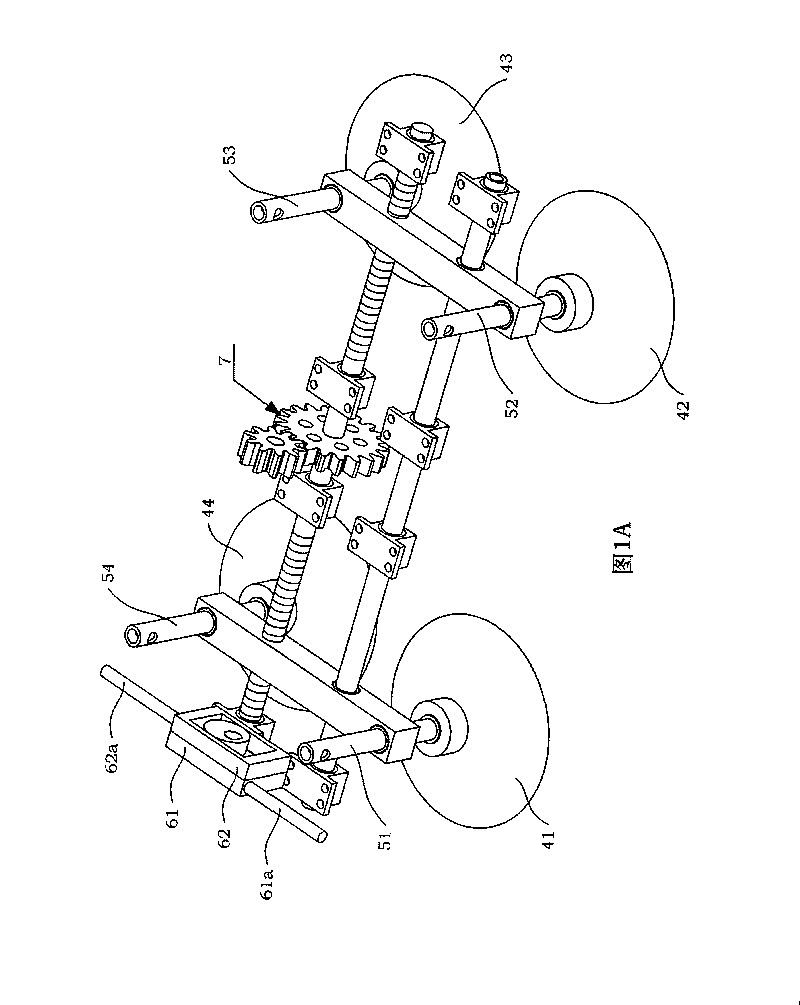

[0054] see figure 1 , Figure 1A As shown, a variable-amplitude sinusoidal vibration adsorption mechanism of the present invention is composed of a vibration unit, a variable-amplitude unit and a base 1 .

[0055] (1) Base

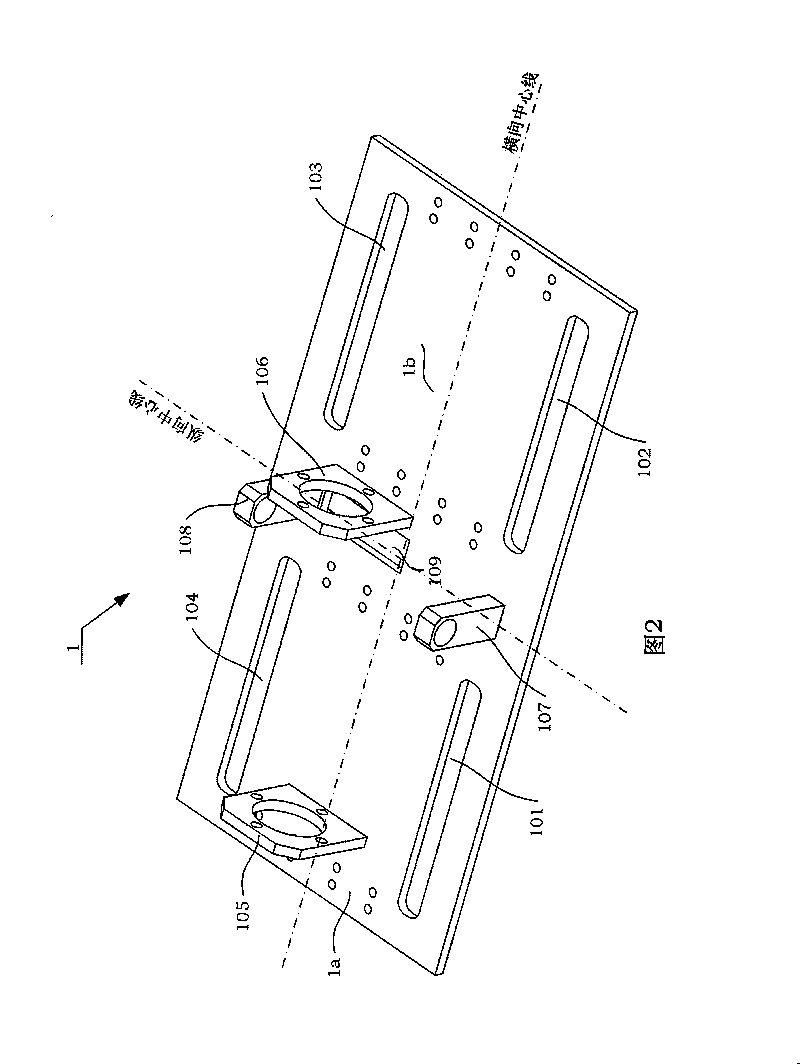

[0056] see figure 2 As shown, the base 1 is provided with A support 107, B support 108, A motor base 105, B motor base 106, and on the front panel 1b of the base 1, there are A chute 101, B Chute 102, C chute 103, D chute 104, gear groove 109; between A chute 101 and B chute 102 is A support 107, between D chute 104 and C chute 103 is B support 108;

[0057] The A chute 101 and the B chute 102 and the D chute 104 and the C chute 103 are symmetrically arranged on both sides of the base 1 with the transverse center line, and these four chutes are respectively used for four guide posts (the A guide post 51 , B guide post 52, C guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com