Weft-wise color spun cotton polyester elastic interwoven jean fabric and preparation method thereof

A technology of denim fabric and cotton polyester elastic, applied in the field of clothing fabrics, can solve the problems of poor color fastness, large skin damage from chemical substances and heavy metals, and large ratio difference, and achieve the effect of improving the gloss of the cloth and rich colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

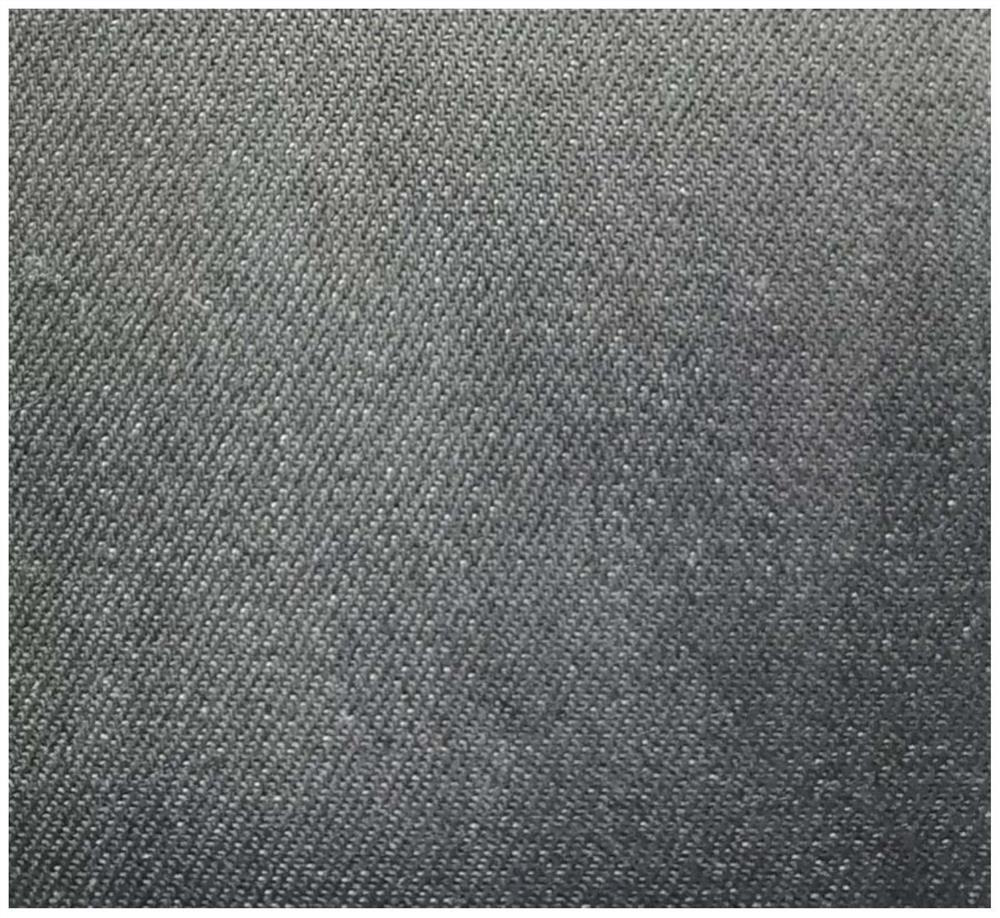

[0018] A weaving color-spun cotton-polyester-elastic interwoven denim fabric of this application, the balls are dyed in extra dark blue, the warp direction is JC53tex, the weft direction is 28.11dtex color-spun light yellow brown, covering 44.4dtex, 425 threads / 10cm, weft density: 244 Roots / 10cm, door width: 148cm, 3 / 1 right slope, unit area: 298g / square meter, long car pre-shrinking machine pre-shrinks the cloth after short car pre-shrinking machine pre-shrinks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com