Oil-displacing agent composition, oil-displacing agent and preparation method and application thereof

A technology of oil displacement agent and composition, which is applied in the field of oil recovery, can solve the problems of reservoir permeability decrease, reservoir environmental pollution, etc., and achieve the effects of less reservoir pollution, increased recovery, and reduced oil-water interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a series of oil displacement agents and preparation methods thereof, the specific preparation process is as follows:

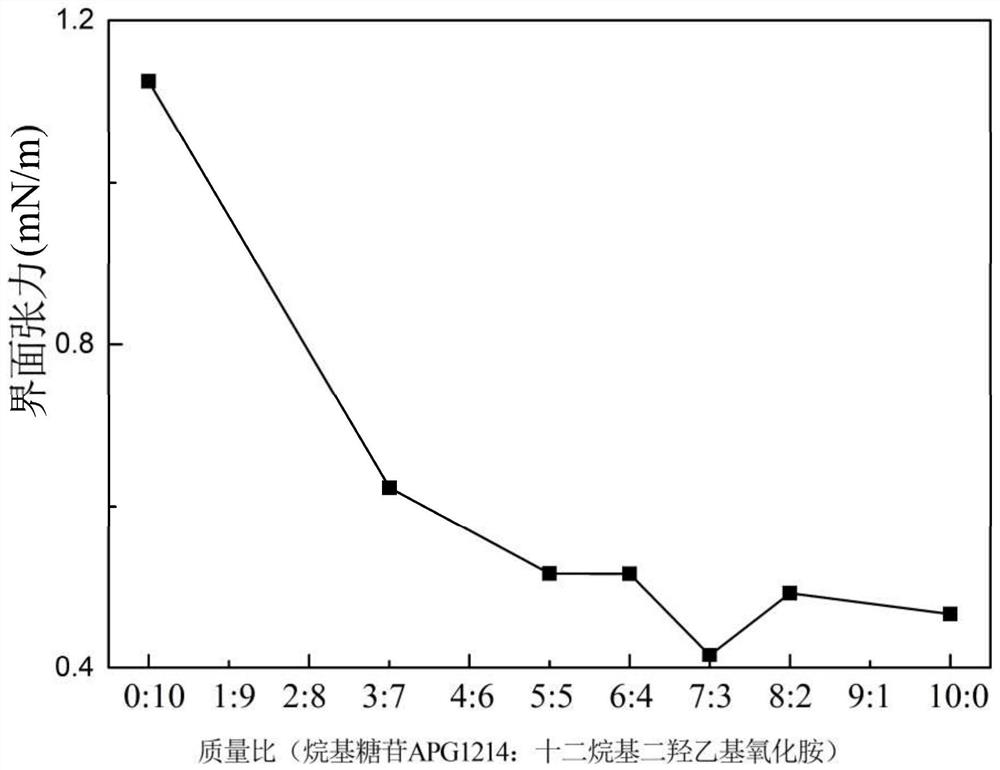

[0040] Dissolve dodecyl dihydroxyethyl amine oxide in deionized water to obtain solution I; dissolve alkyl glycoside APG1214 in water to obtain solution II; The compound mass ratio is 0:10-10:0 for mixing, using a magnetic stirrer to stir for 30 minutes, and is prepared into a 0.5wt% aqueous solution (ie: the total mass of alkyl glycoside APG1214 and dodecyl dihydroxyethyl amine oxide Accounting for the mass concentration of the total oil-displacing agent is 0.5wt%), a series of oil-displacing agents are obtained.

[0041] The crude oil emulsification test is carried out to the oil displacement agent prepared in this embodiment, and the steps are as follows:

[0042] The oil phase is mixed with degassed and dehydrated crude oil from an oilfield and kerosene at a ratio of 1:1, and the water phase is the oil displacement agent pr...

Embodiment 2

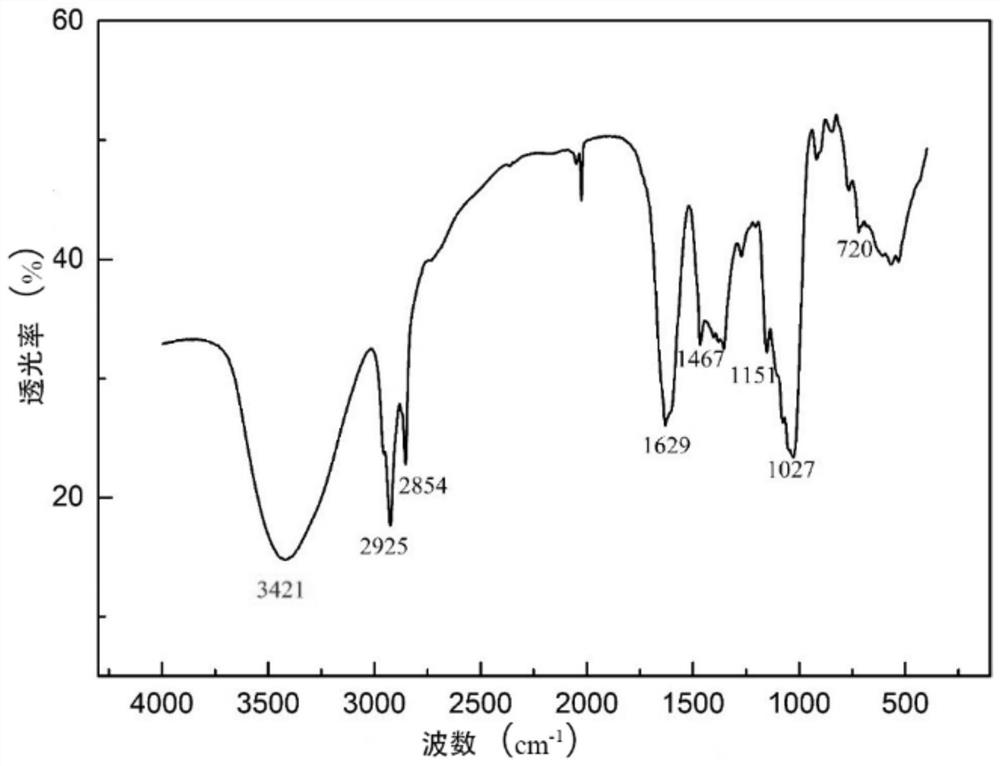

[0046] Embodiment 2: Characterization of structural change of oil displacement agent

[0047] The oil-displacing agent prepared in Example 1 of the present invention, wherein, in the oil-displacing agent, the compounding mass ratio of alkyl glycoside APG1214 to dodecyl dihydroxyethyl amine oxide is 7:3, and alkyl glycoside APG1214 and The total mass of dodecyl dihydroxyethyl amine oxide accounts for 0.5 wt% of the mass concentration of the total oil displacement agent.

[0048] The structure change of the oil displacement agent was characterized by Fourier transform infrared spectrometer, the specific process is as follows:

[0049] An appropriate amount of the above oil displacing agent is freeze-dried, ground and mixed with potassium bromide. The spectrum acquisition adopts a spectral window of 4000-400cm -1 The transmission mode, infrared spectrum test results such as figure 2 shown.

[0050] Depend on figure 2 It can be seen that the free hydroxyl group is a medium-...

Embodiment 3

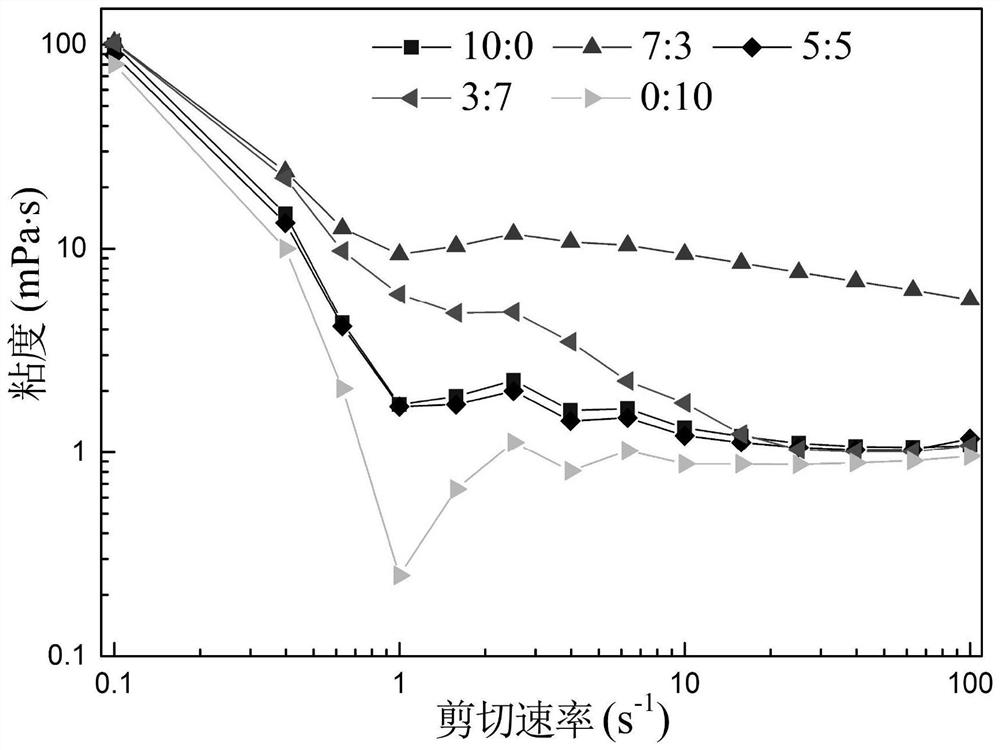

[0053] Embodiment 3: rheological analysis test

[0054] The series of oil displacing agents prepared in Example 1 and the emulsion prepared from the oil phase were subjected to rheological analysis using an Anton Paar rheometer. The set temperature is 30°C, and the shear rate is 0.1-100s -1 , using a coaxial cylinder system to measure the steady-state rheological properties of the emulsion, the experimental results are as follows image 3 shown.

[0055] Depend on image 3 It can be seen that when the mass ratio of alkyl glycoside APG1214 and dodecyl dihydroxyethyl amine oxide is 7:3, the viscosity of the emulsion is the highest, and the diffusion coefficient of the droplet is the lowest at this time, and the resistance of droplet migration The maximum, resulting in the reduction of its collision frequency and coalescence speed, the highest stability of the emulsion. Under continuous shearing, the viscosity reduction rate of this system is obviously lower than that of othe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wave number | aaaaa | aaaaa |

| Wave number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com