Water-based metal anti-corrosion heat-insulation coating for petroleum equipment and preparation method thereof

A metal anti-corrosion and petroleum equipment technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, epoxy resin coatings, etc., can solve the problems of poor heat insulation effect of coatings, easy to rust and anti-corrosion performance, poor adhesion of coatings, etc. Achieve the effects of strong adhesion, novel and scientific formula, and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

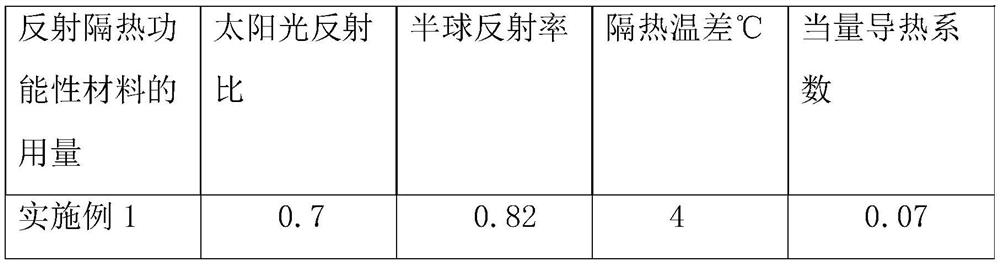

Embodiment 1

[0055] A kind of water-based metal anti-corrosion and heat-insulating coating for petroleum equipment, comprising:

[0056] A: Slurry components:

[0057] 15 parts resin;

[0058] 5 parts of co-solvent; activate the resin, increase the compatibility between resin and acrylic resin, and improve the anti-corrosion performance of the coating film;

[0059] 0.3 parts of the first pH value regulator;

[0060] 0.2 parts of drier, to provide fast, balanced initial drying and good through-drying performance for the coating, and improve the color stability, gloss, coating hardness and water resistance of the coating film;

[0061] 0.6 parts of dispersing agent, dispersing pigment, filler and functional materials, increasing the stability and color development of the coating system, the dispersing agent is selected from polymer copolymers with anchoring groups;

[0062] The first part of defoaming agent is 0.01 part, which eliminates the mechanical bubbles and micro-bubbles generated...

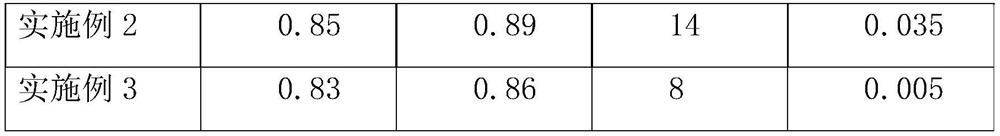

Embodiment 2

[0093] A kind of water-based metal anti-corrosion and heat-insulating coating for petroleum equipment, comprising:

[0094] A: Slurry components:

[0095] 18 parts of resin

[0096] Co-solvent 7 parts

[0097] 0.5 part of the first PH value regulator

[0098] 0.4 parts of drier

[0099] Dispersant 1.2 parts

[0100] The first part of defoamer 0.02 part

[0101] 0.12 parts of anti-settling agent

[0102] Decorative pigment 17.5 parts

[0103] Near-infrared reflective heat insulation material 7.5 parts

[0104] Anti-rust pigment 6 parts

[0105] B: Letting components:

[0106] 58 parts of slurry

[0107] Acrylic emulsion 32.5 parts

[0108] Inorganic composite gel 8 parts

[0109] Coalescing aid 2.5 parts

[0110] The second part of PH value regulator 0.5 parts

[0111] The second part of defoamer 0.25 parts

[0112] Substrate wetting agent 0.3 parts

[0113] Anti-flash rust agent 0.6 part

[0114] 0.4 parts of salt spray resistance additive

[0115] 0.2 parts ...

Embodiment 3

[0123] A kind of water-based metal anti-corrosion and heat-insulating coating for petroleum equipment, comprising:

[0124] A: Slurry components:

[0125] 20 parts of resin

[0126] 10 parts of co-solvent

[0127] The first PH value adjuster 1 part

[0128] 0.6 parts of drier

[0129] Dispersant 2 parts

[0130] The first part of defoamer 0.1 part

[0131] 0.2 parts of anti-settling agent

[0132] Decorative paint 20 parts

[0133] Near-infrared reflective heat insulation material 12 parts

[0134] Anti-rust pigment 10 parts

[0135] B: Letting components:

[0136] 75 parts of slurry

[0137] Acrylic emulsion 40 parts

[0138] Inorganic composite gel 15 parts

[0139] Coalescing aid 3 parts

[0140] 1 part of the second PH value regulator

[0141] The second part of defoamer 0.4 parts

[0142] Substrate wetting agent 0.4 parts

[0143] Anti-flash rust agent 1.0 parts

[0144] 0.6 parts of salt spray resistance additive

[0145] 0.3 parts of fungicide

[0146] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com