Preparation method of medical polyurethane sponge for wound surface sealing negative pressure drainage

A technology of polyurethane sponge and negative pressure drainage is applied in the field of preparation of medical polyurethane sponge, which can solve the problems of high use cost of patients, secondary wound injury, and excessive bleeding of the sponge, achieve secondary injury of light scar wound, inhibit bacterial growth, Anti-adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of preparation method of the medical polyurethane sponge that is used for wound sealing negative pressure drainage, specifically comprises the following steps:

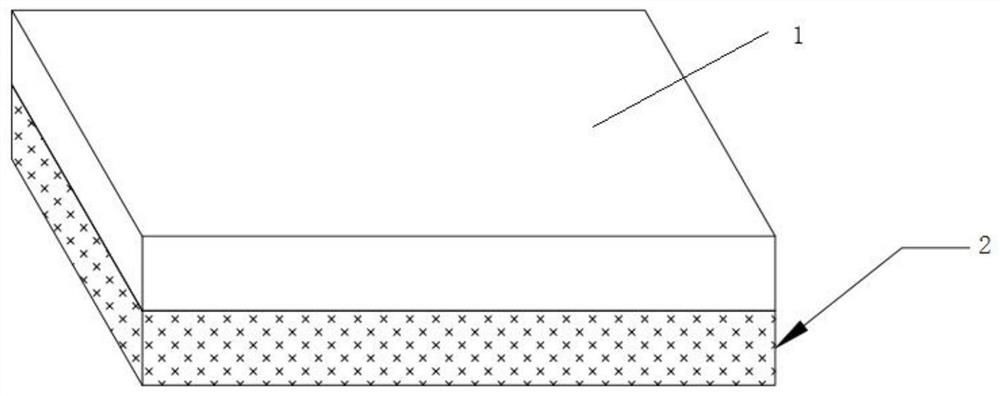

[0021] (1) Pretreatment of the polyurethane sponge: cut the medical polyurethane sponge 1 into 15cm×10cm×3cm; then put it into purified water at a temperature of 30°C for 2 hours, and dry at 50°C for 2 hours.

[0022] (2) Polyurethane sponge soaking solution configuration: the soaking solution consists of 0.05% polyglutamic acid, 0.1% polylysine, 0.1% Phellodendron cortex extract, 0.1% carbomer 980, and the balance is deionized water, of which polyglutamine The molecular weight of acid is 1000kDa, and the molecular weight of polylysine is 9kDa. The process is first to uniformly disperse Phellodendron Phellodendri extract in deionized water, then evenly sprinkle other materials in the formula on the surface of deionized water, leave it overnight, and finally stir evenly.

[0023] (3) Soak the polyurethan...

Embodiment 2

[0026] A kind of preparation method of the medical polyurethane sponge that is used for wound sealing negative pressure drainage, specifically comprises the following steps:

[0027] (1) Medical polyurethane sponge pretreatment: cut the medical polyurethane sponge into 10cm×10cm×3cm; then put it into water for injection at a temperature of 30°C for 2 hours, and dry at 60°C for 2 hours.

[0028] (2) Configure the soaking solution: the soaking solution is composed of 0.1% polyglutamic acid, 0.05% polylysine, 0.2% Phellodendron cortex extract, 0.1% growth factor, 0.5% gelatin, and the balance is deionized water, wherein polyglutamine The molecular weight of acid is 800kDa, and the molecular weight of polylysine is 10kDa. The process is first to uniformly disperse Phellodendron Phellodendri extract in deionized water, then evenly sprinkle the solid materials in the formula on the surface of deionized water, leave it overnight, and finally add growth factors and stir evenly.

[00...

Embodiment 3

[0032] A kind of preparation method of the medical polyurethane sponge that is used for wound sealing negative pressure drainage, comprises the following steps:

[0033] (1) Medical polyurethane sponge pretreatment: cut the medical polyurethane sponge into 10cm×10cm×3cm; then put it into water for injection at a temperature of 30°C for 2 hours, and dry at 60°C for 2 hours.

[0034] (2) Configure the soaking solution: the soaking solution is composed of 0.1% polyglutamic acid, 0.05% polylysine, 0.25% Phellodendron cortex extract, 0.1% growth factor, 0.15% carbomer 940, 0.1% mupirocin, and The amount is deionized water, wherein the molecular weight of polyglutamic acid is 50kDa, and the molecular weight of polylysine is 10kDa. The process is first to uniformly disperse Phellodendron Phellodendri extract in deionized water, then evenly sprinkle the solid materials in the formula on the surface of deionized water, leave it overnight, and finally add growth factors and stir evenly....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com