Moisture-proof modified phenolic heat insulating material and preparation method thereof

A thermal insulation material and phenolic technology, which is applied in the field of moisture-proof modified phenolic thermal insulation materials and its preparation, can solve problems affecting the use and storage life, and achieve stable and controllable weight gain, wide and cheap raw material sources, and good compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of a moisture-proof modified phenolic heat insulating material, the method comprises the following steps:

[0030] (1) Preparation of hydrophobic agent: the hydrophobic modifier is mixed with a solvent to obtain a hydrophobic agent with hydrophobic modification function;

[0031] (2) hydrophobization reaction: adding the hydrophobic agent to the phenolic heat insulating material for heat preservation to carry out the hydrophobization reaction;

[0032] (3) Drying: after the hydrophobization reaction is completed, under in-situ conditions, the excess hydrophobization reagent is removed by heating to obtain a moisture-proof modified phenolic heat insulating material.

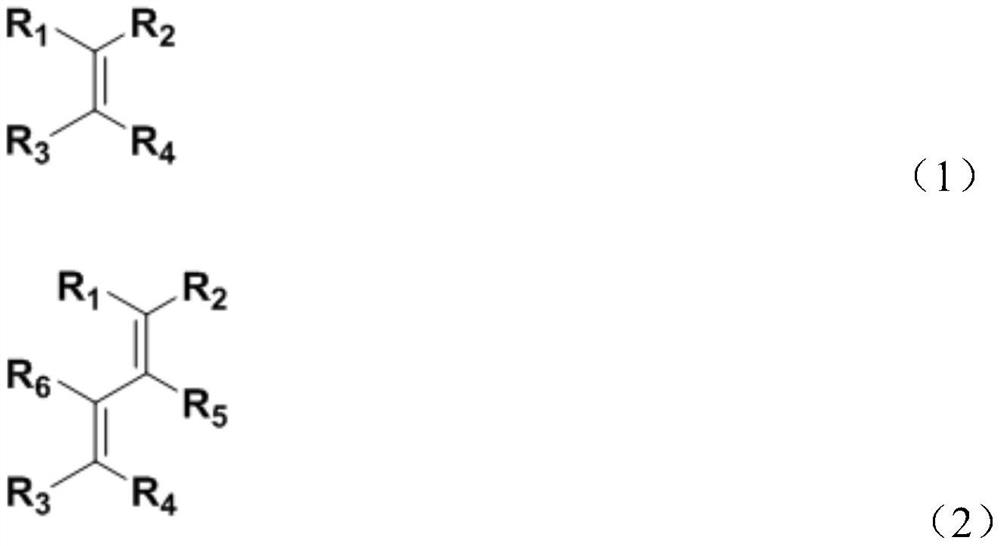

[0033] Further, in step (1), the hydrophobic modifier is selected from a reagent having a molecular structure represented by formula (1) or formula (2):

[0034]

[0035]

[0036] where R 1 Choose from -H, -CN, -NO 2 , -SO 2 R7, -SO 2 N R 7 R 8 , -COR 7 , -COOR 7 , -CONR ...

Embodiment 1

[0060] Take the size as 500mm×500mm×30mm, density 0.5g / cm 3 , a piece of commercially available phenolic aerogel composite material without moisture-proof treatment with a room temperature thermal conductivity of 0.06W / (m·K), placed in a tank with a height of 800mm and a Φ800mm, and kept the atmosphere connected at 60 ℃. 4h. Under the condition of maintaining the same temperature, the tank was evacuated to a vacuum, and then 187.5g of methyl acrylate was inhaled, and then the tank was closed and kept at 60 °C for 12 hours. The surface of the material is in a hydrophobic state, the weight gain of the material is 2%, the moisture absorption rate is 0.8%, and the change of thermal conductivity at room temperature is less than 1%.

Embodiment 2

[0062] Take the size as 500mm×500mm×30mm, density 0.5g / cm 3 , a piece of commercially available phenolic aerogel composite material without moisture-proof treatment with a room temperature thermal conductivity of 0.06W / (m·K), placed in a tank with a height of 800mm and a Φ800mm, and kept the atmosphere connected at 60 ℃. 4h. Under the condition of maintaining the temperature unchanged, the tank was evacuated to a vacuum, and then a mixture of 187.5g methyl acrylate and 187.5g acetone was inhaled, and the tank was closed and kept at 60 °C for 12 hours. The surface of the material is in a hydrophobic state, the weight gain of the material is 2.5%, the moisture absorption rate is 0.6%, and the thermal conductivity at room temperature does not change <1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com