Motor stator automatic bending forming welding fixture

A bending forming and motor stator technology, applied in motors, welding equipment, electric vehicles, etc., can solve problems such as inconvenient operation, inaccurate fixture positioning, and low work efficiency, and achieve low labor intensity, high production efficiency, zero The effect of scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

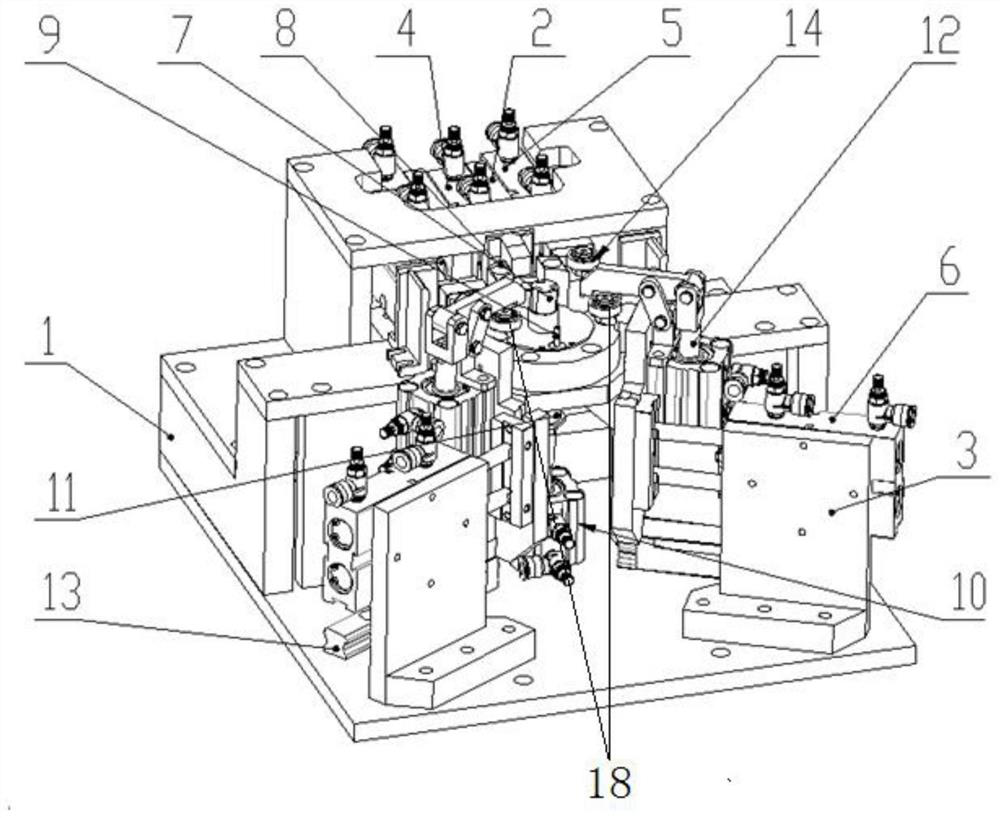

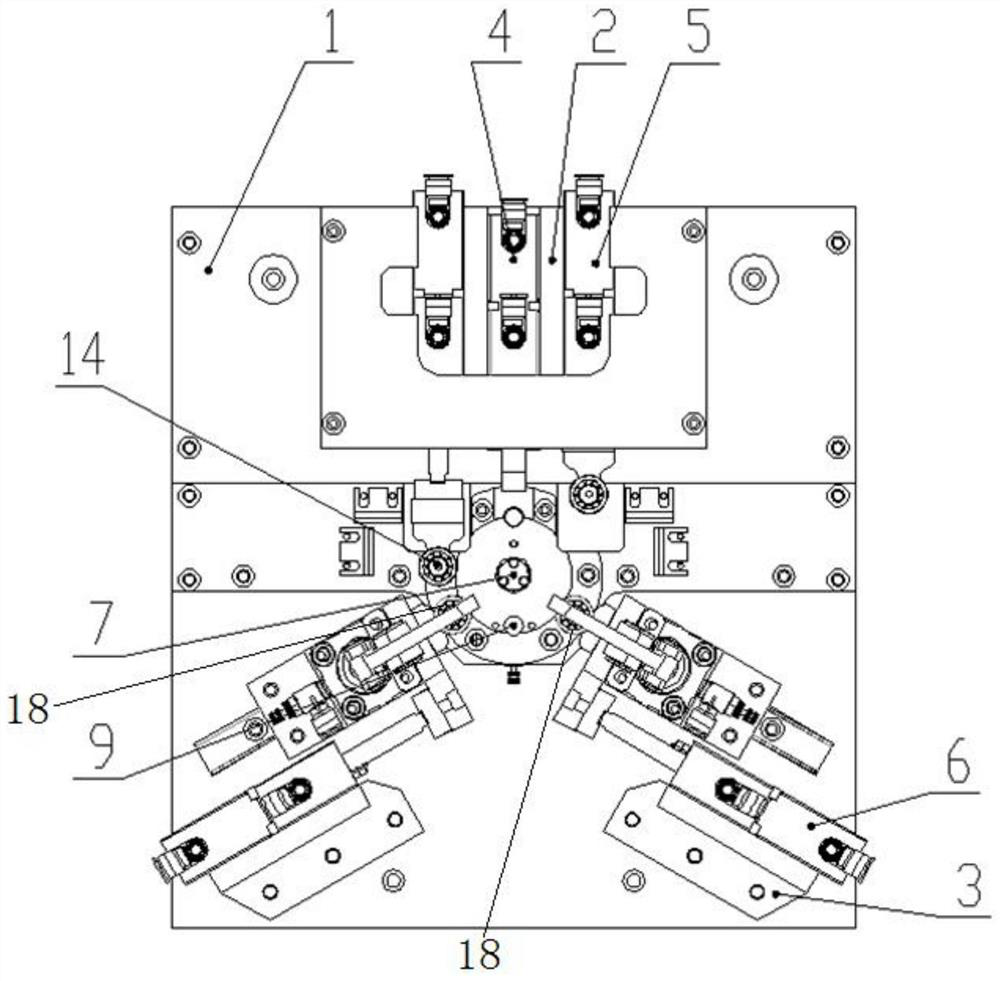

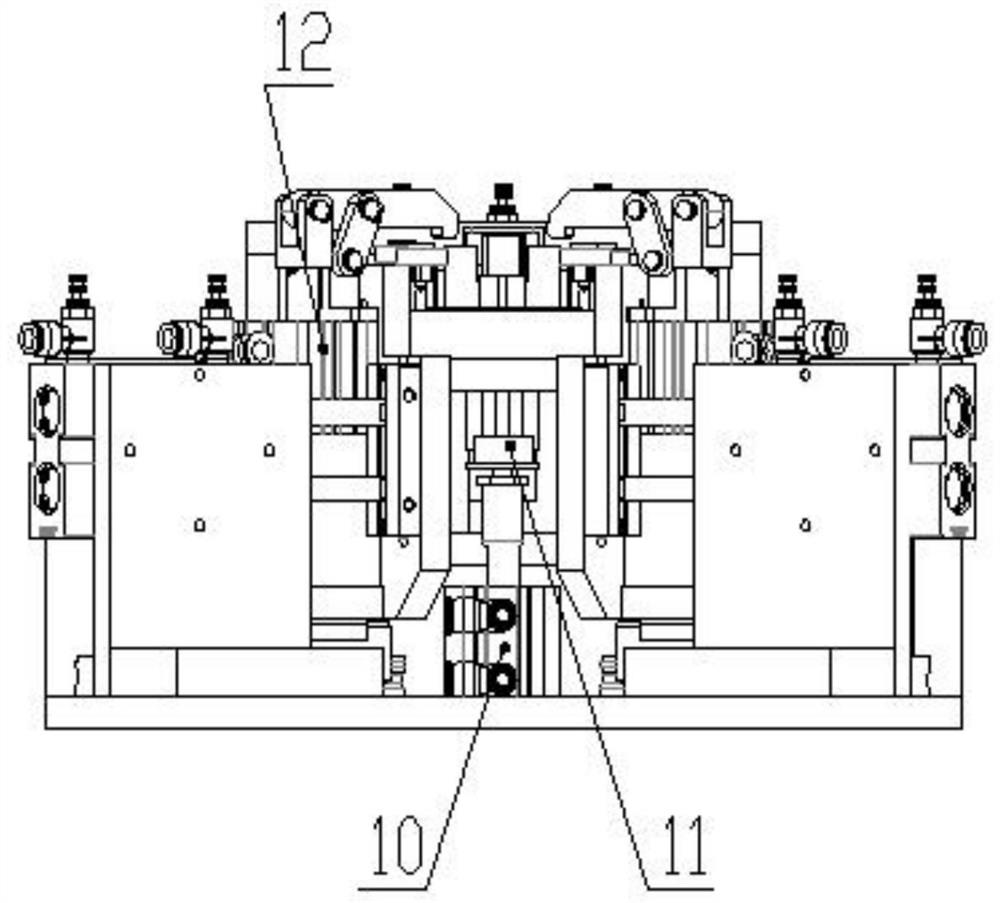

[0024] see figure 1 - Figure 9 , An automatic bending forming welding fixture for a motor stator of the present invention includes a fixture bracket, two once-bending forming cylinder mounting plates, two once-bending forming cylinders, two bending and secondary forming cylinder mounting plates, two Bending overmolding cylinder, two linear guides, two one-shot bending bearings, two overmolding bending bearings, clamping cylinder, centering module, positioning module, fixed height module, jacking cylinder, jacking The pin, the elbow clamp cylinder, the two bending one-time forming cylinder mounting plates, the two bending secondary forming cylinder mounting plates, the centering module, the positioning module, the height-fixing module, and the jacking cylinder are respectively fixed on the fixture bracket, The two one-time bending forming cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com