Gear finish machining device and method

A processing device and gear refinement technology, which is applied to gear tooth manufacturing devices, metal processing equipment, belts/chains/gears, etc., can solve the problem of long grinding time in the grinding process, weakening of the life of the gear grinding machine, and high difficulty of grinding. and other problems, to achieve the effect of simple and fast installation, improved accuracy and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

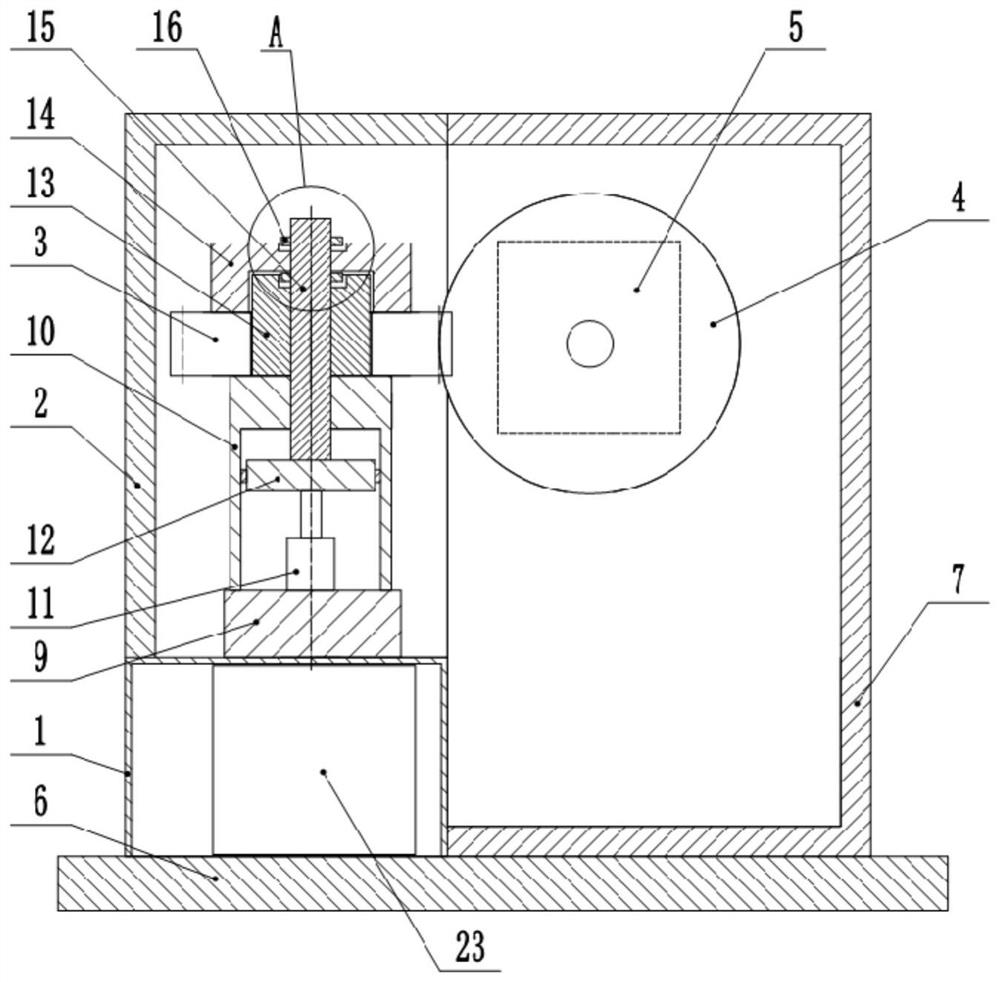

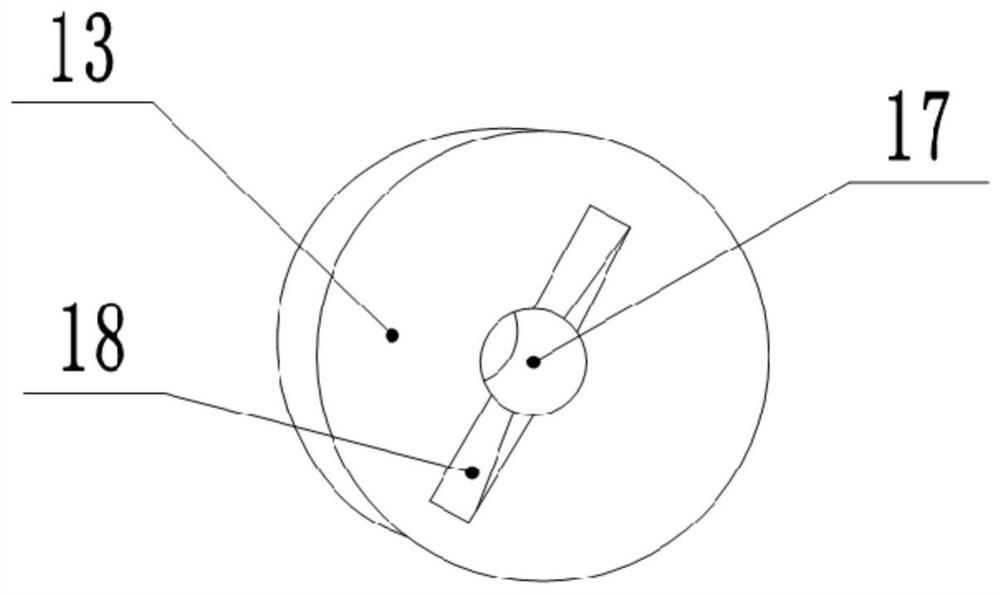

[0036] The embodiment is basically as attached figure 1 Shown: the gear finishing device includes a tool installation unit and a gear installation unit. The tool installation unit includes a frame 7 and a tool. The frame 7 is equipped with a driver 5 for driving the tool. The tool in this embodiment is a grinding wheel 4 , the driving part 5 is used to drive the grinding wheel 4 to move up and down reciprocally, and the driving part 5 can adopt the driving parts such as gear and rack mechanism, hydraulic cylinder and so on in the prior art.

[0037] In this embodiment, the gear installation unit includes a mounting table 1 and a clamp. A rotating part that drives the clamp to rotate is installed on the mounting table 1. In this embodiment, a motor is used for the rotating part. In this embodiment, a bottom plate 6 is also provided at the bottom of the mounting table 1. The mounting table 1 is slidably connected to the base plate 6, and the mounting table 1 is provided with a p...

Embodiment 2

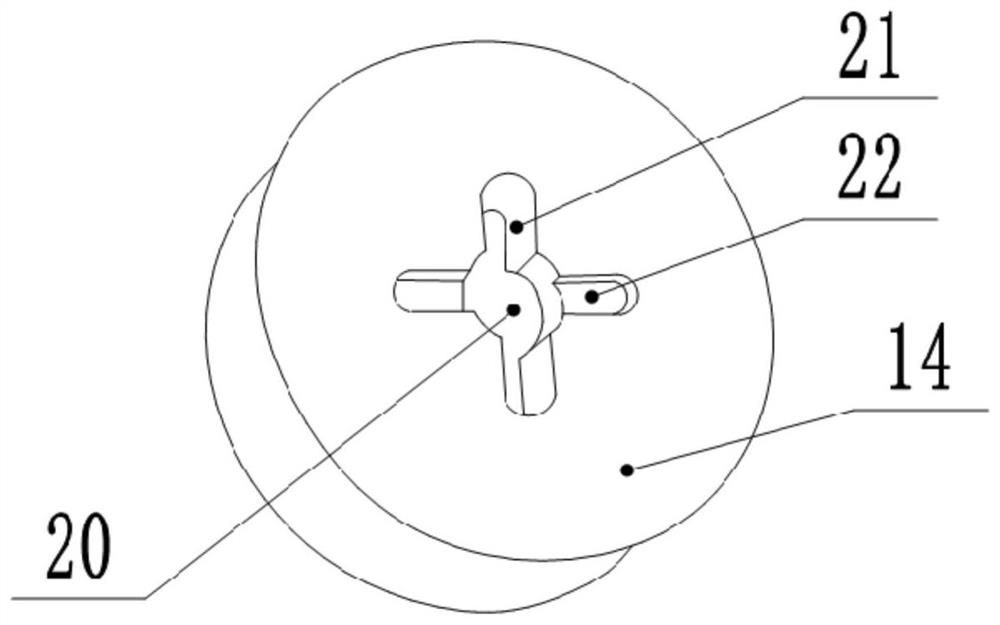

[0050] Such as Figure 5 As shown, the difference between the gear finishing device and Embodiment 1 is that in this embodiment, an annular groove 24 is provided on the top of the fixed column 13, and four segmented blocks 25 are welded and fixed in the annular groove 24. The four segmented blocks 25 Evenly distributed along the circumferential direction of the annular groove 24 .

[0051] Such as Image 6 As shown, the bottom end of the cover 14 is integrally formed with four moving blocks 26, the four moving blocks 26 are evenly distributed along the circumferential direction of the cover 14, and the four moving blocks 26 can be inserted into the annular groove 24, and when the four When the moving blocks 26 are respectively inserted into the annular grooves 24 between the adjacent partition blocks 25 and are respectively against the four partition blocks 25, the through groove 21 on the blocking cover 14 is opposite to the stop block 16 on the positioning shaft 15. It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com