Straightening and wire feeding device of prefabricated reinforced concrete pipe reinforcement cage seam welder

A technology for reinforced concrete pipes and wire feeding devices, applied in the direction of online nets, other household appliances, household appliances, etc., can solve the problems of secondary bending deformation of wires, uneven structure of steel cages, derailment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

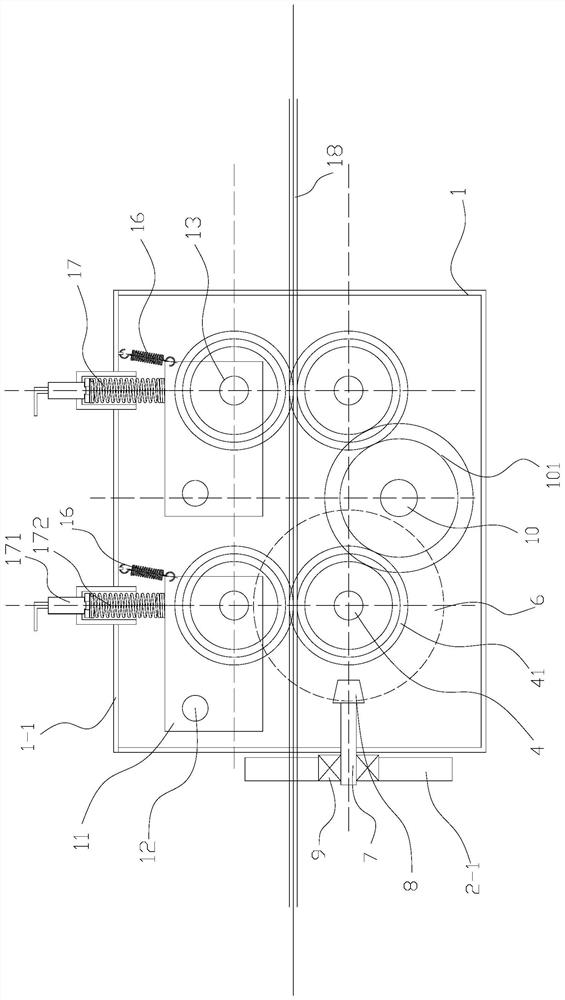

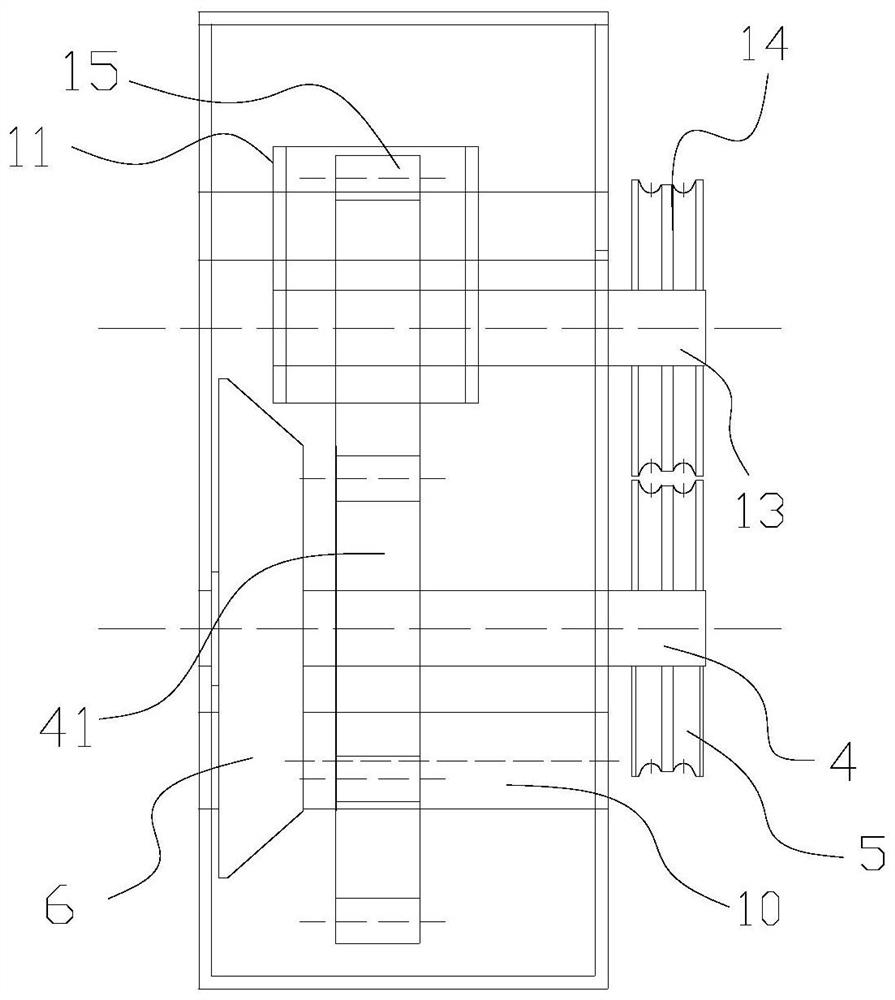

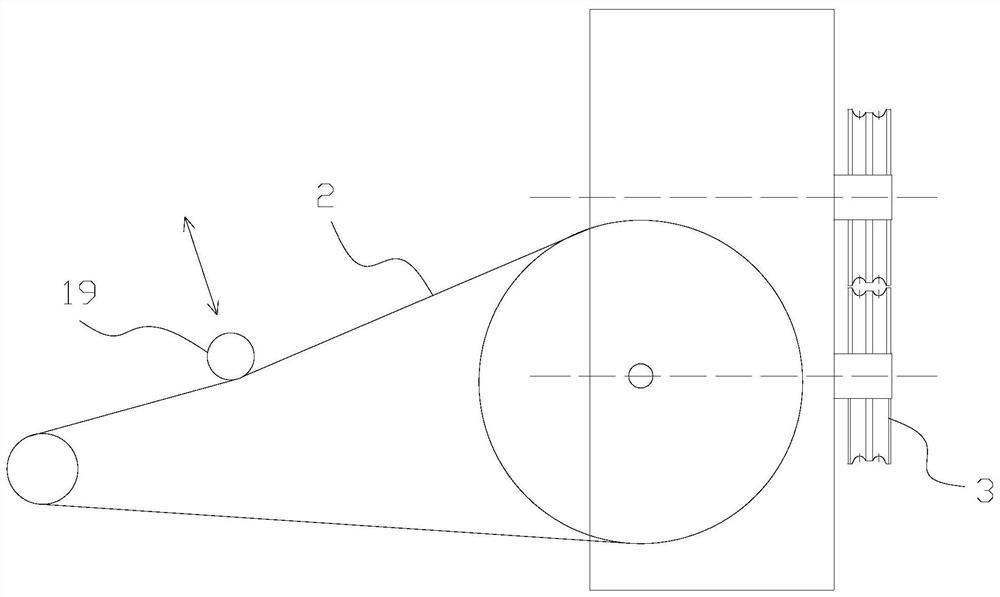

[0028] This example Figure 1-4 As shown, a straightening wire feeding device of a steel cage roll welding machine for prefabricated reinforced concrete pipes includes a chassis 1, a drive motor, a belt transmission group 2, and a guide roller group 3. The guide roller group includes an auxiliary roller 14 and a main roller 5, and its characteristics is that

[0029] At least two main shafts 4 are arranged in parallel between the front and the back side of the lower part of the cabinet 1; one end of the two main shafts 4 stretches out from the cabinet 1, and the two main shafts 4 stretch out from the cabinet. Main rollers 5 are respectively arranged on the shaft head;

[0030] One of the main shafts 4 of the two main shafts 4 is provided with a large bevel gear 6, an input shaft 7 is provided on the side wall of the casing 1, and a small bevel gear 8 is arranged on the shaft head of the input shaft. The small bevel gear 8 meshes with the large bevel gear 6 (realizes the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com