Ultra-large coil pipe production system and production method thereof

A production system and ultra-large plate technology, applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problems of high investment cost, limited production speed, high energy consumption, etc., achieve convenient operation process, reduce production cost, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

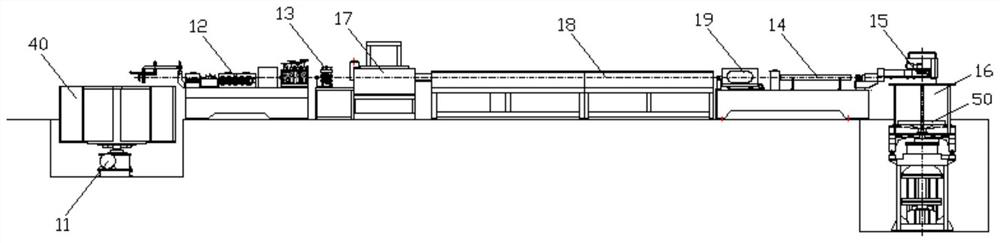

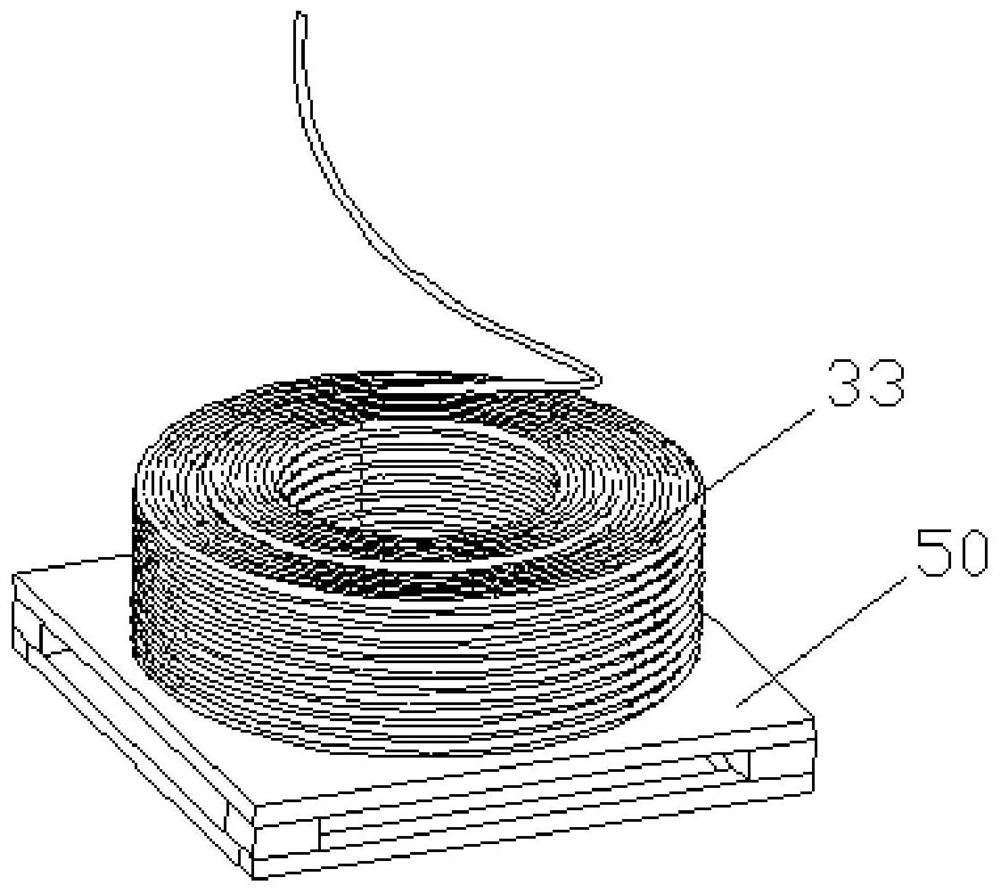

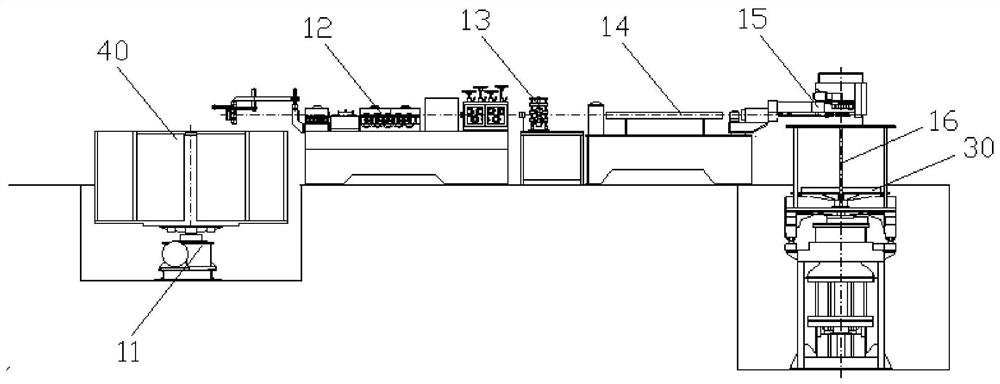

[0035] Example: such as Figure 3-8As shown, a super-large coil pipe production system includes a discharge device 11 for receiving and releasing metal pipes to be processed, a straightening device 12 for straightening the pipes, and a device for measuring the length of the straightened pipes. The length measuring device 13, the inkjet drying device 14 for inkjet and drying of the pipe, the forming device 15 for bending and forming the pipe, the winding and unloading device for winding and unloading the pipe Material device 16, roller hearth furnace and transfer device 20, described transfer device 20 includes handling forklift 22 and transfer table 23, described winding and unloading device 16 will pipe rewinding on stainless steel holder 30, described pipe is on stainless steel holder 30 The roller hearth furnace is used to anneal the ultra-large pipe 33 on the stainless steel tray, and the forklift truck 22 transports the annealed stainless steel tray 30 loaded with the ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com