Nanometer Cu-Fe3O4@peanut shell carbon composite material as well as preparation method and application thereof

A technology of cu-fe3o4 and peanut shell charcoal, which is applied in chemical instruments and methods, water/sludge/sewage treatment, metal/metal oxide/metal hydroxide catalysts, etc. Agglomeration and other problems, to achieve the effect of a wide range of sources, rich surface functional groups, and reduce agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of nano Cu-Fe 3 o 4 @Peanut shell charcoal composite material, its preparation method includes the following steps:

[0038]1), the peanut shell powder with a particle size of 0.250-0.355mm (obtained after washing, drying, crushing and sieving) of the peanut shell is placed in a tubular heating furnace, and then the peanut shell powder is placed in a nitrogen atmosphere (nitrogen Heat up to 500°C at a flow rate of 150mL / min) at a heating rate of 10°C / min, then heat-retain and carbonize for 1 hour, cool to room temperature, add the carbonized product to 0.5mol / L dilute hydrochloric acid solution, stir for 60 minutes, and filter with suction. Wash with boiling water until the filtrate is neutral, then dry to obtain peanut shell charcoal;

[0039] 2), adding FeCl to ethylene glycol 3 , CuCl 2 And mix evenly, then add peanut shell charcoal to the mixed solution, stir for 1 hour, then add sodium acetate therein, stir and mix evenly, to obtain the precursor solutio...

Embodiment 2

[0061] A kind of nano Cu-Fe 3 o 4 @Peanut shell charcoal composite material, its preparation method includes the following steps:

[0062] 1), the peanut shell powder with a particle size of 0.250-0.355mm (obtained after washing, drying, crushing and sieving) of the peanut shell is placed in a tubular heating furnace, and then the peanut shell powder is placed in a nitrogen atmosphere (nitrogen Heat up to 550°C at a rate of 7°C / min at a flow rate of 220mL / min, then keep warm and carbonize for 40 minutes, cool to room temperature, then add the carbonized product to 0.7mol / L dilute hydrochloric acid solution, stir for 50 minutes, and filter with suction. Wash with boiling water until the filtrate is neutral, then dry to obtain peanut shell charcoal;

[0063] 2), adding FeCl to ethylene glycol 3 , CuCl 2 And mix evenly, then add peanut shell charcoal to the mixed solution, stir for 1.5h, then add sodium acetate therein, stir and mix evenly, to obtain the precursor solution; ...

Embodiment 3

[0069] A kind of nano Cu-Fe 3 o 4 @Peanut shell charcoal composite material, its preparation method includes the following steps:

[0070] 1), the peanut shell powder with a particle size of 0.250-0.355mm (obtained after washing, drying, crushing and sieving) of the peanut shell is placed in a tubular heating furnace, and then the peanut shell powder is placed in a nitrogen atmosphere (nitrogen The flow rate is 300mL / min), and the temperature is raised to 600°C at a heating rate of 5°C / min, and then carbonized for 30 minutes, cooled to room temperature, and then the carbonized product is added to 1mol / L dilute hydrochloric acid solution, stirred for 70 minutes, filtered with suction, and the filter residue is Wash with boiling water until the filtrate is neutral, then dry to obtain peanut shell charcoal;

[0071] 2), adding FeCl to ethylene glycol 3 , CuCl 2 And mix evenly, then add peanut shell charcoal to the mixed solution, stir for 2 hours, then add sodium acetate ther...

PUM

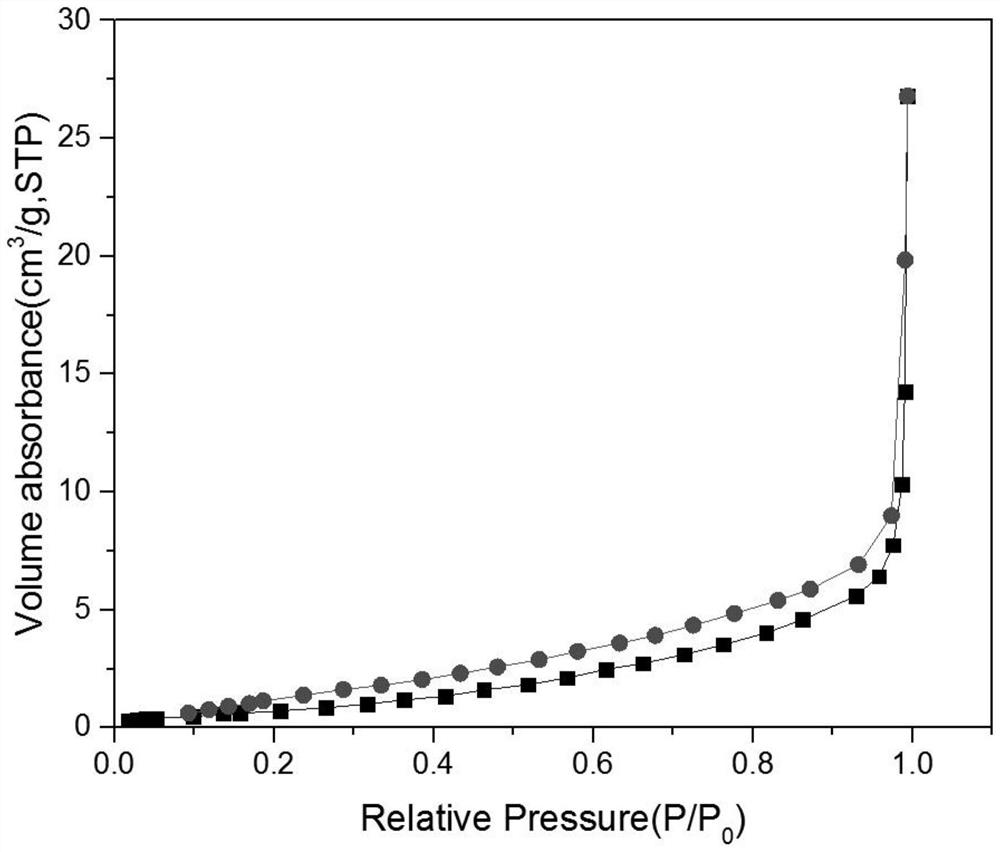

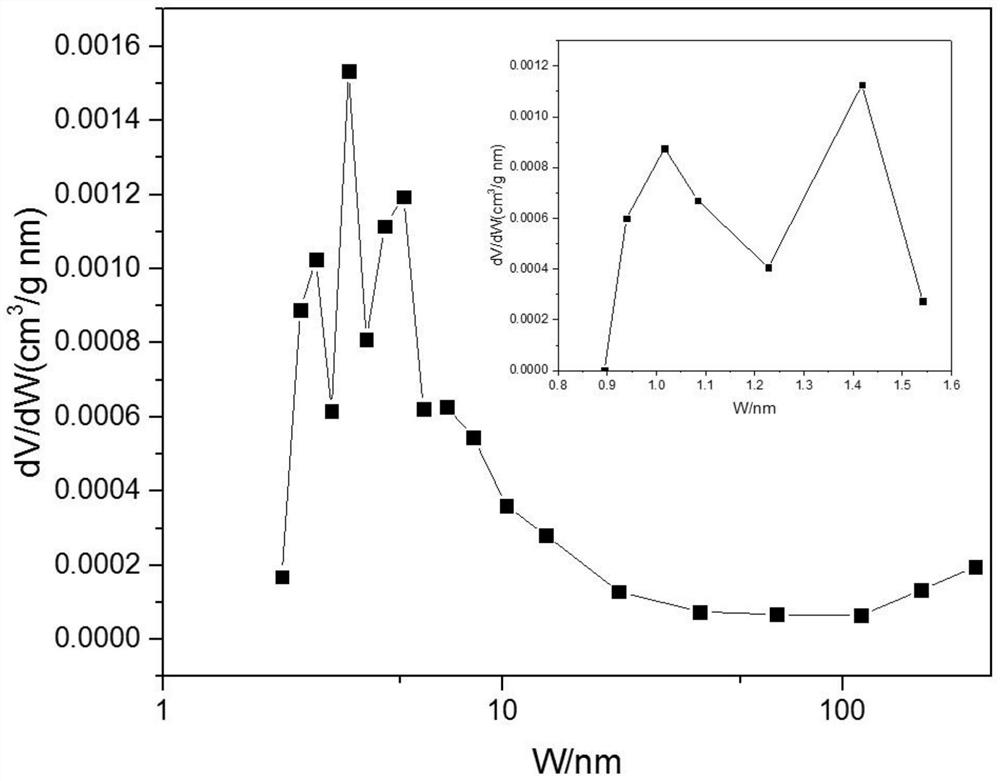

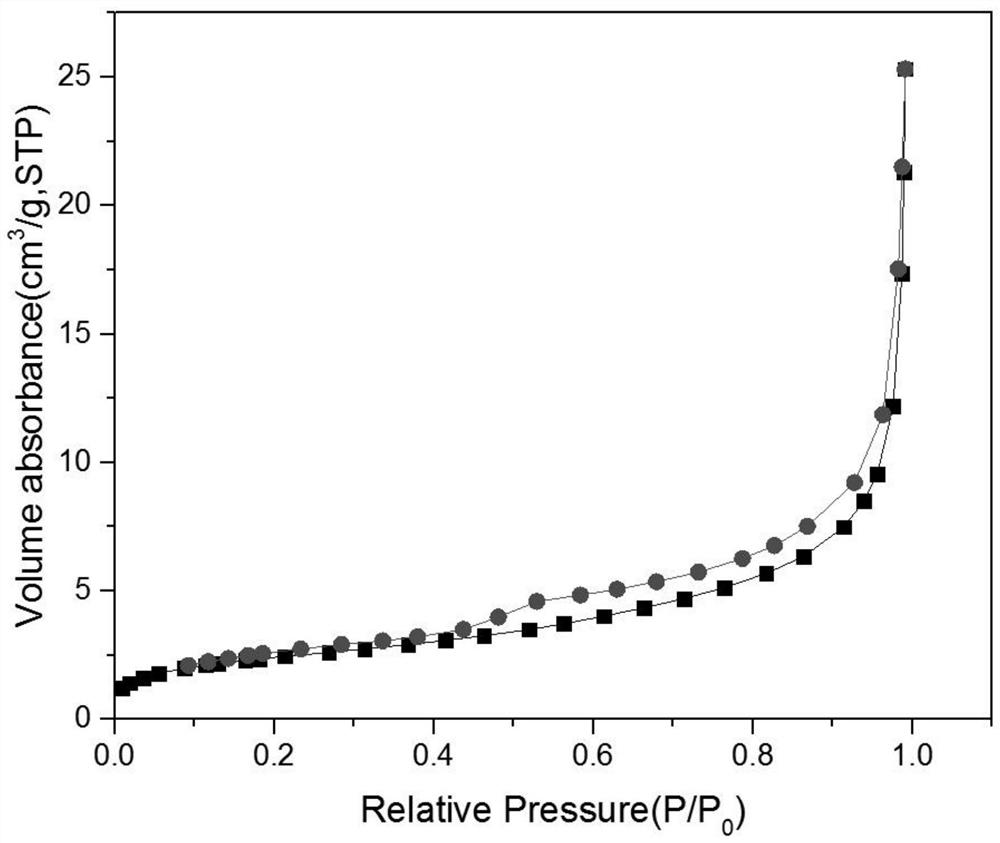

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com