Reverse osmosis membrane repairing agent and reverse osmosis membrane offline repairing method

A technology of reverse osmosis membrane and repair agent, which is applied in semi-permeable membrane separation, osmosis/dialysis water/sewage treatment, reverse osmosis, etc. There are substantial improvements and other issues to achieve the effect of saving solid waste treatment costs, improving economic and social benefits, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The configuration of the repair agent:

[0025] Ingredients and content of agent A: polydimethylvinylpropylammonium chloride 10%, glutaraldehyde 30%, purified water 60%; ingredients and content of agent B: polyethylene glycol 7.5%, sodium polyacrylate 35%, pure Water 57.5%.

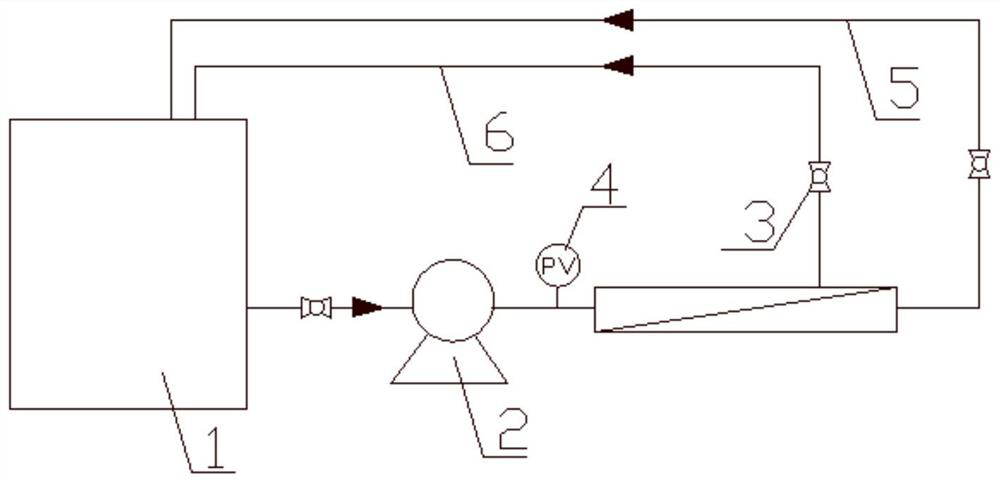

[0026] Off-line repair method of reverse osmosis membrane: Off-line cleaning refers to removing the oxidized reverse osmosis membrane at the customer site, and then installing it into the reverse osmosis membrane repair equipment for repair.

[0027] The first step: acid cleaning the reverse osmosis membrane first, the acid cleaning pressure is 0.4bar, the pH of the acid cleaning is 2.6, and the acid cleaning time is 20min. The washing pH is 11.3, and the alkaline washing time is 20 minutes;

[0028] The second step: carry out alkali washing on the reverse osmosis membrane after cleaning. The alkali washing solution is sodium lauryl sulfate aqueous solution, the alkali washing pressure is 0.4 bar...

Embodiment 2

[0038] The configuration of the repair agent:

[0039] Ingredients and content of agent A: dodecyl dimethyl benzyl ammonium chloride 9%, glutaraldehyde 31%, purified water 60%; ingredients and content of agent B: polyethylene glycol 8%, sodium polyacrylate 35% , Purified water 57%.

[0040] Off-line repair method of reverse osmosis membrane: Off-line cleaning refers to removing the oxidized reverse osmosis membrane at the customer site, and then installing it into the reverse osmosis membrane repair equipment for repair.

[0041] The first step: acid cleaning the reverse osmosis membrane first, the acid cleaning pressure is 0.3bar, the pH of the acid cleaning is 2.4, and the acid cleaning time is 20min. The washing pH is 11.6, and the alkaline washing time is 20 minutes;

[0042] The second step: carry out alkali washing on the reverse osmosis membrane after cleaning, the alkali washing solution is sodium lauryl sulfate aqueous solution, the alkali washing pressure is 0.3 ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com