Part for a turbomachine centrifugal breather having a filtering mesh

A breather, centrifugal technology, applied in the direction of turbine/propulsion lubrication, centrifuge, engine components, etc., can solve the problem of restricting the best geometry, and achieve the effect of easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the drawings, for the sake of illustration and clarity, scale and ratios have not been strictly adhered to.

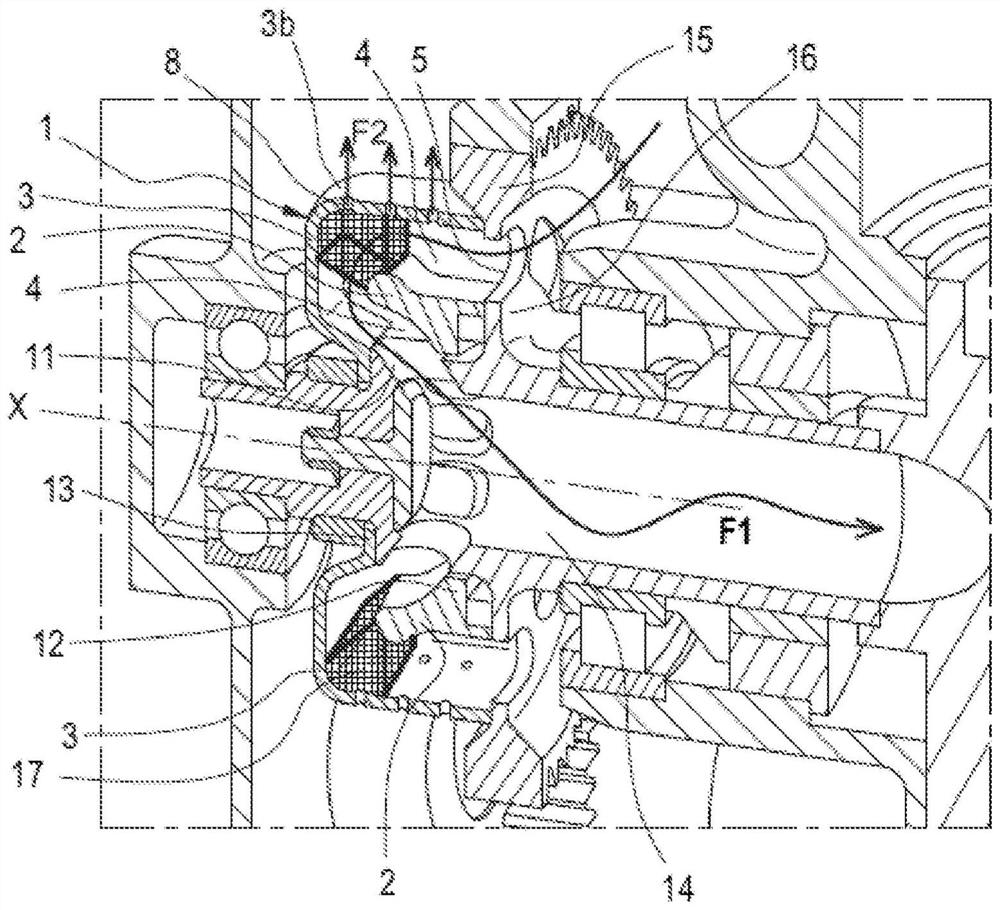

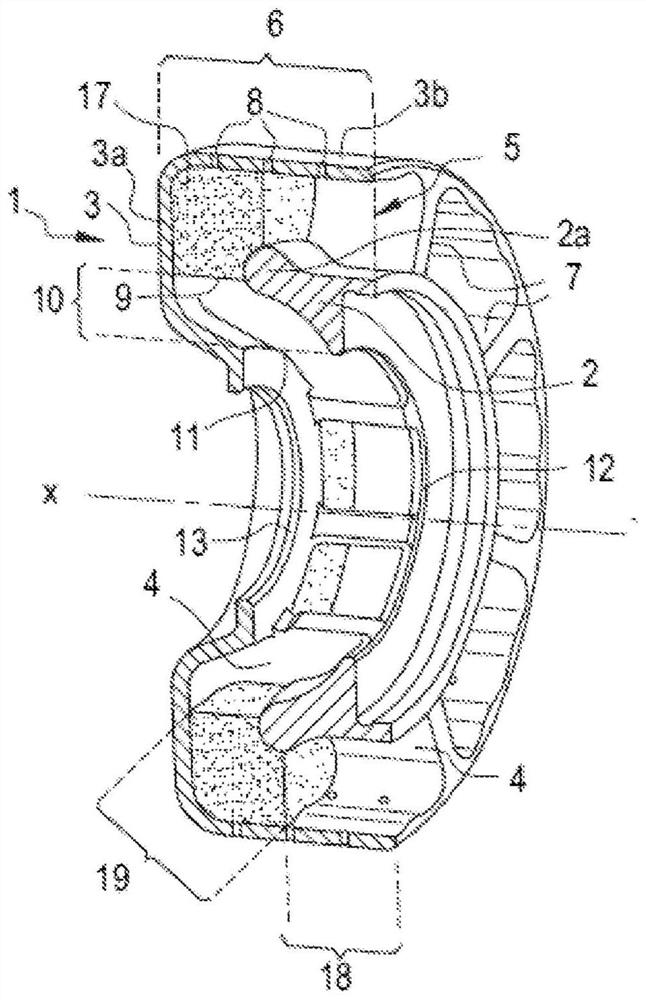

[0041] likefigure 1 As shown, the aerator using the invention comprises a movable part 1 rotating around a longitudinal axis of symmetry X. like figure 2 Shown in more detail, said movable part 1 comprises a structural part comprising a first housing 2 surrounded by a second housing 3 . The space between the two housings 2 , 3 forms a duct 4 rotating about the central axis of symmetry X for the circulation of the air / oil mixture to be separated.

[0042] The duct 4 comprises an axial inlet 5 for the entry of the air / oil mixture to be separated. This axial inlet 5 corresponds to one end of the first part 6 of the duct 4 which extends substantially axially for centrifuging the mixture. The first part 6 of the axially extending duct acts as a centrifuge housing, since at this first part of the axially extending duct the centrifugal force is exerted with maxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com