Hard cutting pile-forming construction method for secant piles in high-water-level complex geological area

A technology of complex geology and construction methods, applied in drilling equipment and methods, sheet pile walls, earthwork drilling and mining, etc., can solve problems such as inability to form holes, ensure construction quality, more controllable pile quality, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0035] A hard-cut pile construction method for occlusal piles in complex geological areas with high water levels, the steps of which are as follows:

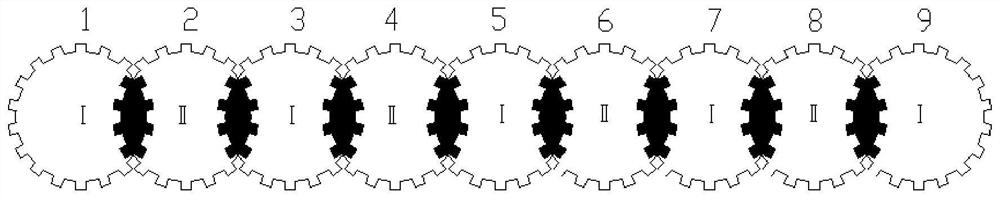

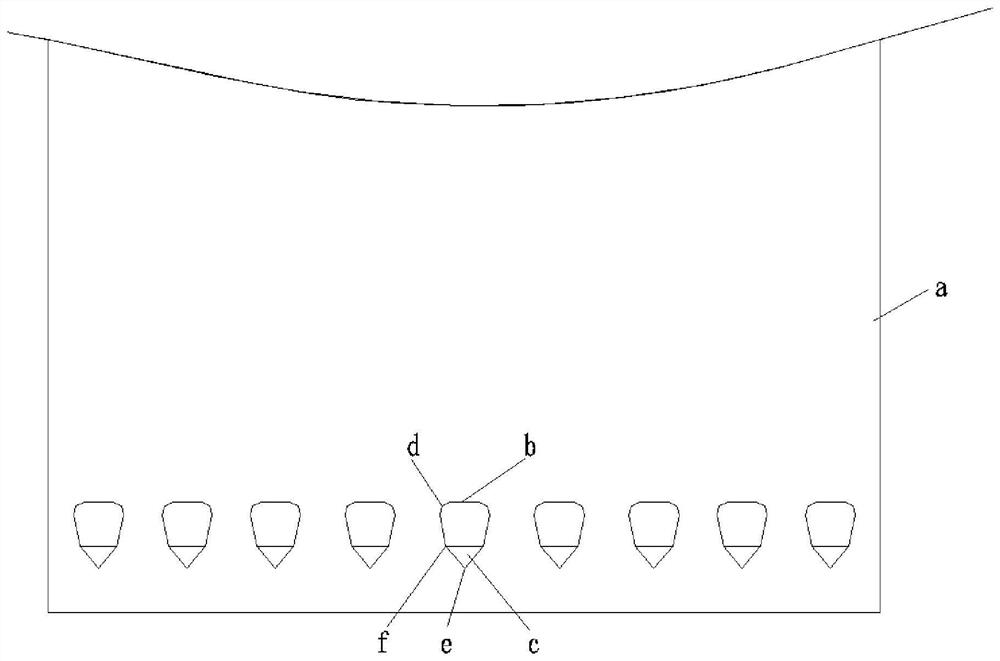

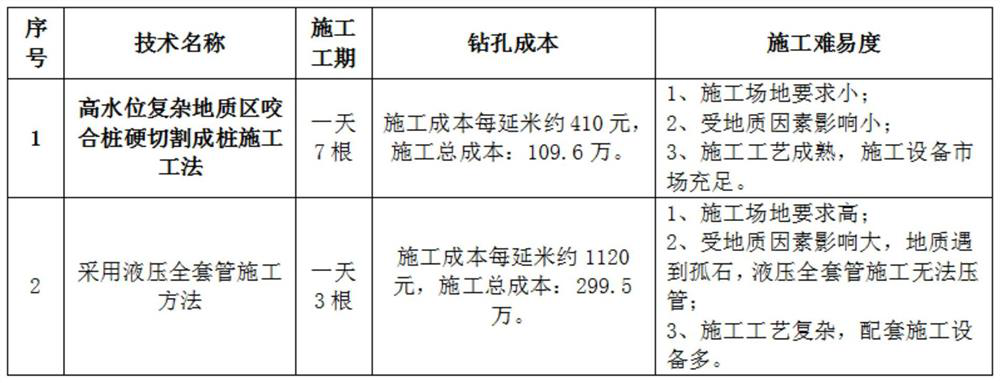

[0036] S1. Number each pile position in sequence according to 1, 2, 3, 4, 5, 6...; the odd number is the plain concrete pile position, and the even number is the reinforced concrete pile position; figure 1 As shown, 1, 3, 5, 7, and 9 are plain concrete piles (collectively referred to as I piles); 2, 4, 6, and 8 are reinforced concrete piles (collectively referred to as II piles). Compared with plain concrete piles, reinforced concrete piles need to lower the reinforcement cage before pouring concrete.

[0037] S2. First construct plain concrete piles, use a rotary drilling rig to drill holes, and then pour concrete to form plain concrete piles; the construction of plain concrete piles is separated by more ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com