Membrane element for flat membrane bioreactor and flat membrane bioreactor

A bioreactor and membrane element technology, applied in the direction of sustainable biological treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of low filling density of flat membrane bioreactor, increase of manufacturing cost of flat membrane There are few water-producing channels on the surface of the layer, so as to reduce the manufacturing cost, operating cost and floor area, improve the stability of the device, and reduce the thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

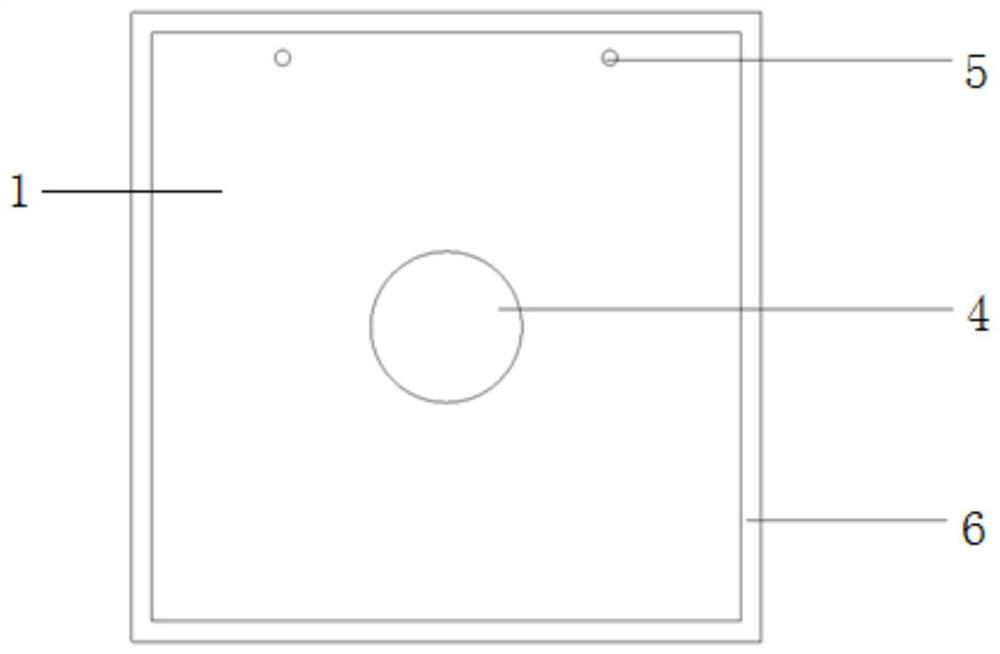

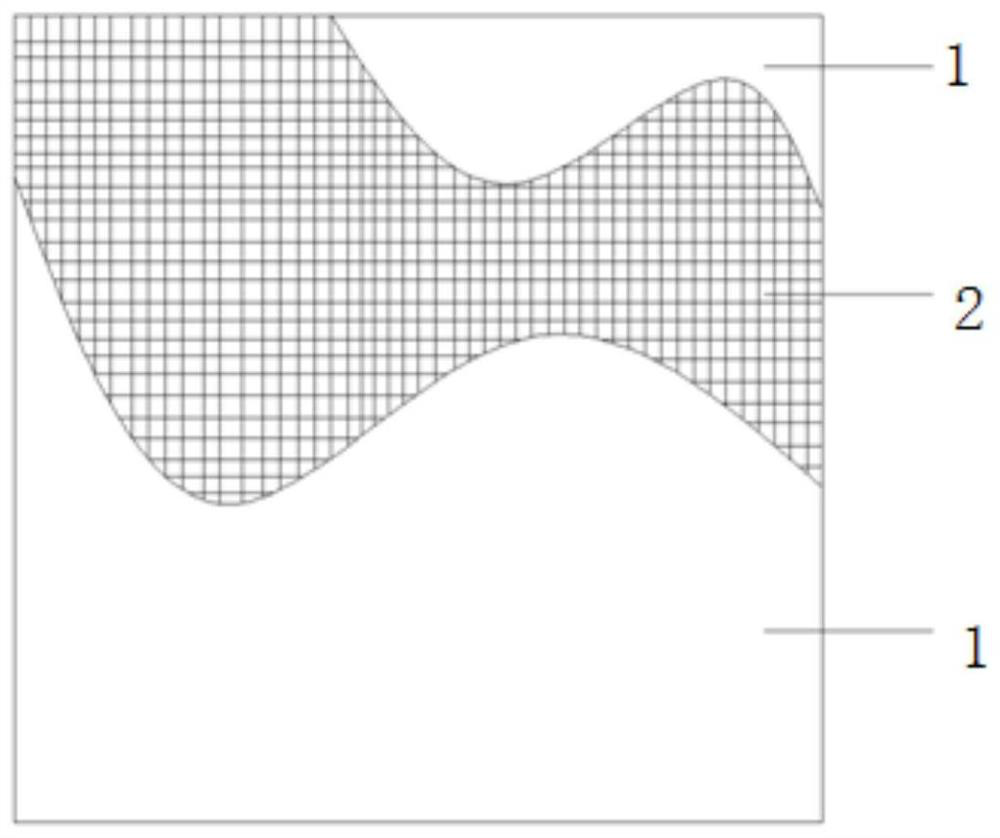

[0063] figure 1 A schematic diagram of the membrane element used in the flat membrane bioreactor of the present embodiment is shown; figure 2 The internal structure diagram of the membrane element used in the flat-plate membrane bioreactor of the present embodiment is shown.

[0064] like figure 1 , figure 2 As shown, the membrane element used for the flat membrane bioreactor is rectangular, with a length of 270 mm, a width of 270 mm and a thickness of 0.6 mm, including a first filter membrane layer 1, a mesh layer that are stacked in sequence and connected at the edges by welding 2. The second filter membrane layer 3, the welding width 6 is 6 mm, and the inner membrane cavity is formed between the first filter membrane layer 1 and the mesh layer 2, and between the mesh layer 2 and the second filter membrane layer 3, wherein the mesh The material of the grid layer 2 includes polyethylene;

[0065] The center of the membrane element is provided with a water production por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com