Slicing device for potato processing

A slicing device and potato technology, which is applied in metal processing and other directions, can solve the problems such as the inability to realize the adjustment of the cutter spacing, the inability to meet the needs of different thickness slices, and the limited use range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

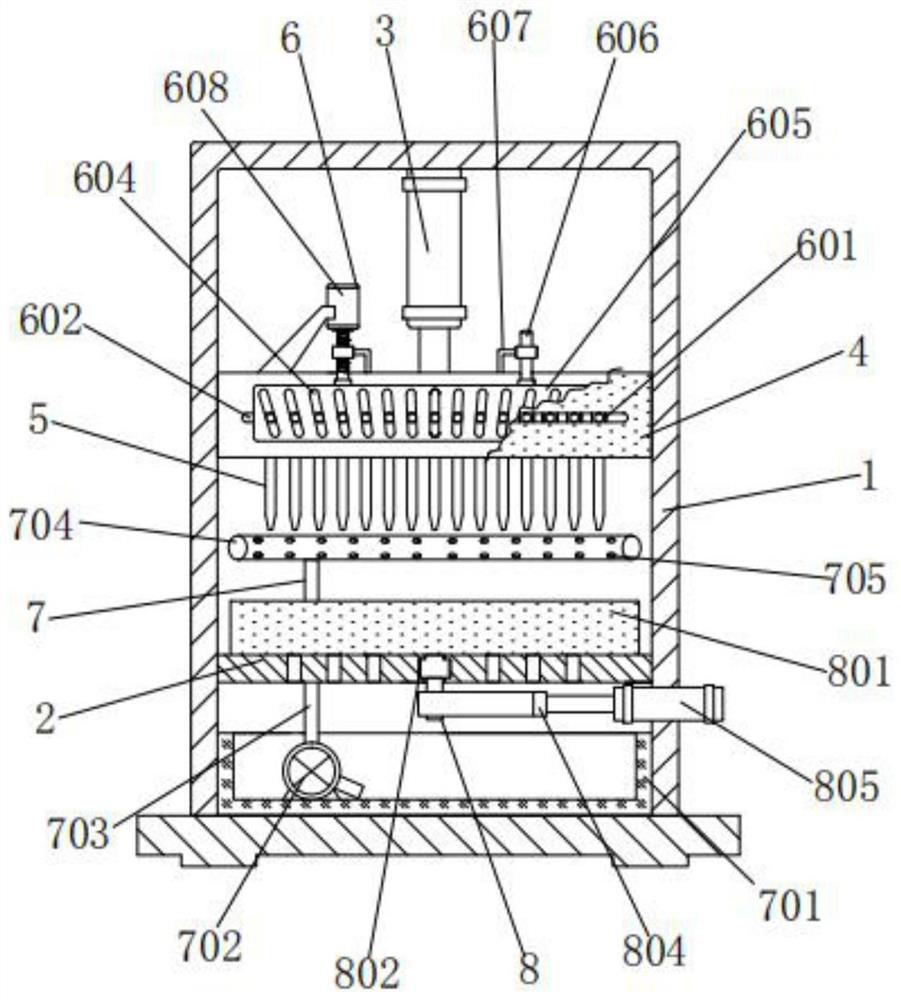

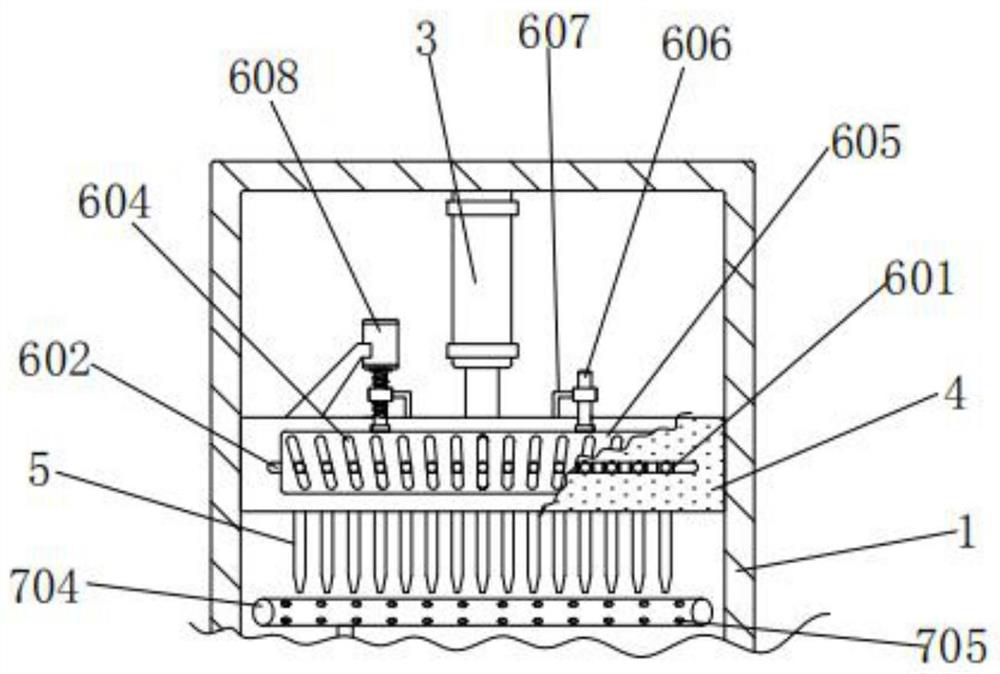

[0032] A slicing device for potato processing, comprising a body 1, an orifice 2 is arranged below the inner wall of the body 1, the outer wall of the orifice 2 is fixedly connected with the inner wall of the body 1, and a box 4 is arranged above the orifice 2, and the box 4 The outer wall of the body 1 is matched with the inner wall of the body 1, the top of the box body 4 is fixedly connected with the telescopic rod of the first cylinder 3, the top of the first cylinder 4 is fixedly connected with the top center of the inner wall of the body 1, and the inside of the box body 4 is equipped with multiple A cutting knife 5, the cutting knife 5 is lateral equidistant distribution, and cutting edge all vertically downwards is arranged, and design makes section thickness consistent like this.

Embodiment 2

[0034] As an option, see figure 1 , 2 , 4 and 5, potato processing slicing device, the front of casing 4 is provided with adjusting assembly 6, and adjusting assembly 6 comprises square bar 601, transverse groove 602, round bar 603, chute 604, vertical plate 605, pole 606, Collar 607 and motor 608, the bottom of square bar 601 is fixedly connected with the top of cutter 5, and the outer wall of square bar 601 cooperates with the inwall clearance of casing 4 through transverse groove 602, and transverse groove 602 plays guiding role to bar 601 of the other side, The front of the square rod 601 is provided with a round rod 603, the rear end of the round rod 603 is fixedly connected with the positive end face of the square rod 601, the outer wall gap of the round rod 603 is equipped with a chute 604, and the chute 604 is equidistantly arranged concentrically and radially, and The chute 604 and the round rod 603 form a sliding structure, so that when the vertical plate 605 slides...

Embodiment 3

[0037] As an option, see Figure 1-3, potato processing slicing device, the bottom of the body 1 is provided with a spray assembly 7, the spray assembly 7 includes a water tank 701, a water pump 702, a vertical pipe 703, an arc pipe 704 and a through hole 705, the bottom of the water tank 701 and the body 1 The bottom of the inner wall is fixedly connected. The inner wall of the water tank 701 is provided with a water pump 702. The model of the water pump 702 is L0. The bottom of the water pump 702 is installed on the left side of the bottom of the inner wall of the water tank 701. The bottom is connected with the output end of the water pump 702, the top of the vertical pipe 703 is provided with an arc tube 704, the bottom of the arc tube 704 is connected with the top of the vertical tube 703, the front of the arc tube 704 is processed with a through hole 705, through which The holes 705 are arranged in double rows, which can make the spraying of the cutter 5 avoid adhesion; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com