Vibration detection device for mechanical arm manufacturing

A vibration detection, robotic arm technology, applied in manipulators, manufacturing tools, etc., can solve the problems of uncontrollable, damaged robotic arm stability, low vibration frequency, etc., to increase stability, improve convenience, and facilitate movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

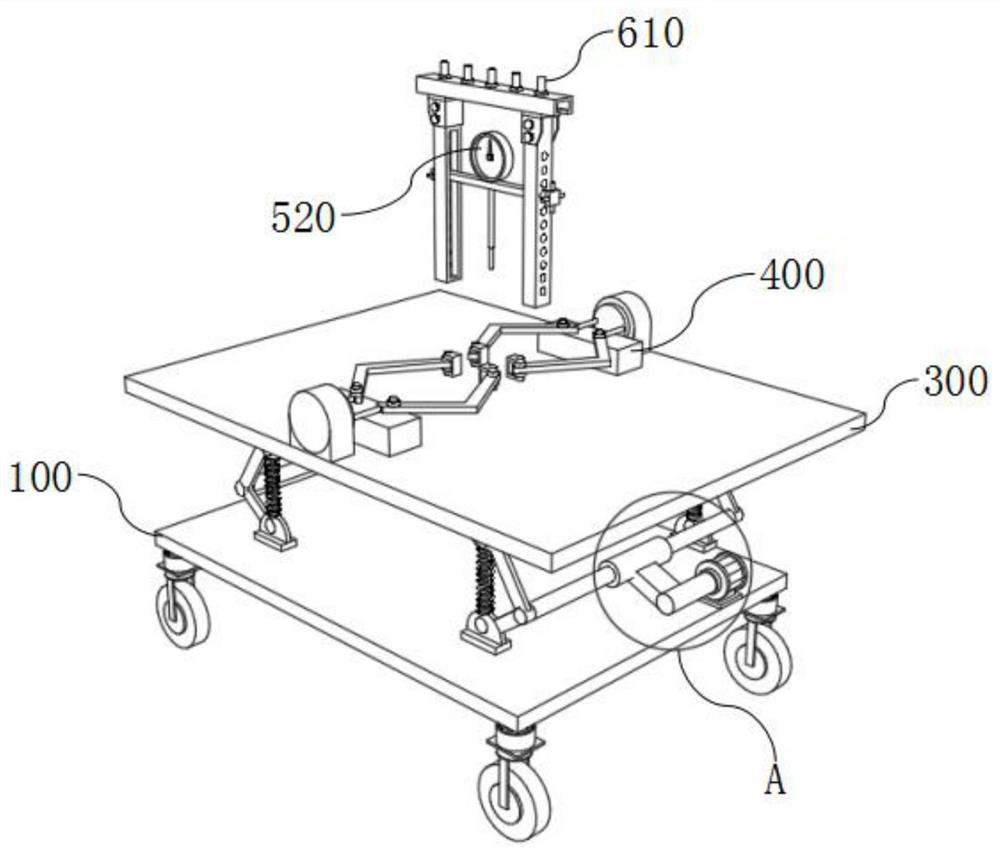

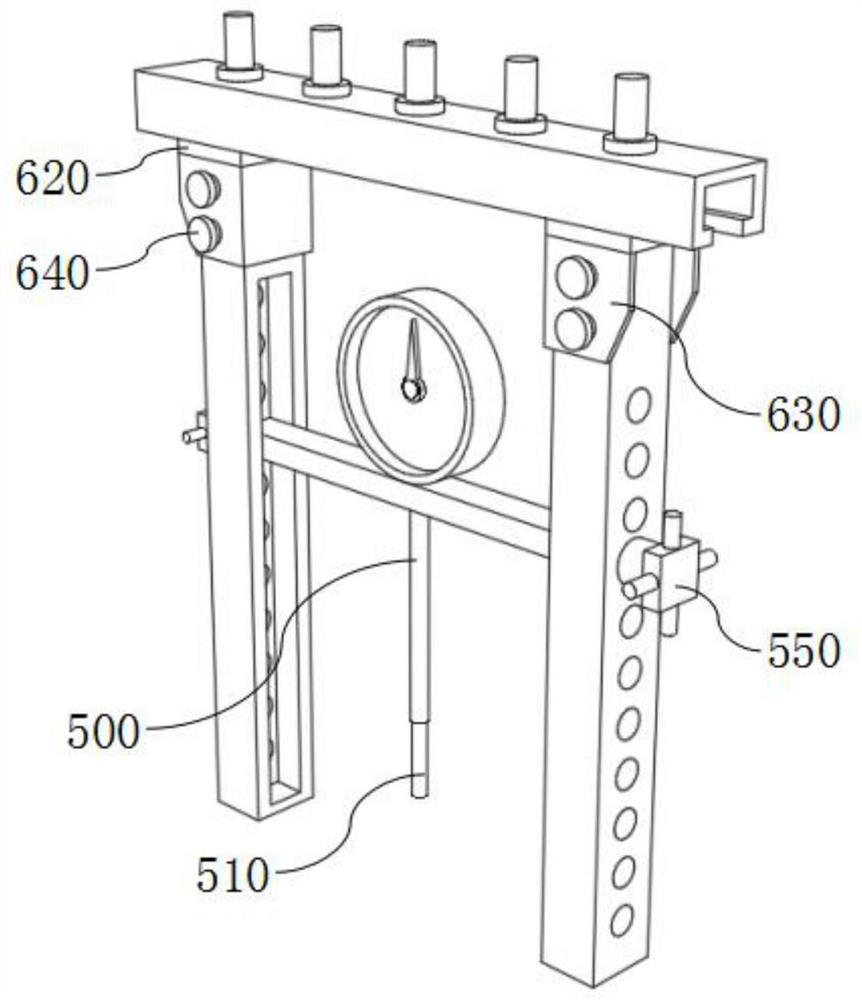

[0032] see Figure 1-7 As shown, the present invention is a vibration detection device manufactured by a mechanical arm, including a base 100, a drive mechanism 200, a vibration mechanism 300, a clamping mechanism 400, a detection mechanism 500 and a fixed frame 600, the base 100 includes a base body, and the drive mechanism 200 Including a driving mechanism body, a driving bar 230, a bearing tube 240 and a driving tube 250, the vibrating mechanism 300 includes a vibrating mechanism body, a first vibrating bar 320, a second fixed block 330 and a second vibrating bar 340, and the clamping mechanism 400 includes a clamping Mechanism body and clamping oil cylinder 410, detection mechanism 500 includes slide rail 540, fixed frame 600 includes clamping block 630 and clamping bolt 640, the lower surface of several driving mechanism bodies is welded with the upper surface of base body, and one end of two driving bars 230 is respectively It is welded to the side surfaces of two bearin...

Embodiment 2

[0040] see Figure 1-7 As shown, the present invention is a vibration detection device manufactured by a mechanical arm, wherein the model of the driving motor 210 is Y2-80M2-6, and the model of the clamping cylinder 410 is SC-DR40*20ST. 250 and the bearing tube 240 reduce the friction coefficient of the driving motor 210, increase the rotational power of the driving motor 210, speed up the vibration frequency, make the detection effect better, and can adjust the output efficiency of the driving motor 210 to control the vibration The frequency makes the detection control and adjustment more convenient. The first vibrating bar 320 and the second vibrating bar 340 convert the rotational motion brought by the drive tube 250 into a feed motion, thereby driving the vibrating mechanism body to vibrate, and the connecting spring 350 increases the stability. To prevent excessive vibration frequency from causing damage to the device, the clamping cylinder 410 pushes the piston rod 420 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com