A kind of synthetic lubricating cleaning oil for aluminum alloy mig welding wire

A technology for synthesizing lubricating oil and aluminum alloy, which is applied in welding equipment, welding medium, metal processing equipment, etc. It can solve the problems of unstable combustion, pores in the weld seam, and difficulty in cleaning, so as to improve the pores on the welding surface and stabilize the welding resistance , the effect of stable delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Synthetic lubricating and cleaning oil for aluminum alloy MIG welding wire, by weight, is composed of the following raw materials:

[0025] Extreme pressure antiwear additive 5%

[0026] Among them: the anti-wear additive is obtained by compounding 65% thiophosphoramidate, 0.01% 1-hydroxyethylidene-1,1-diphosphonic acid (dioctyl) ester (HEDP) and 34.99% isooctyloxyborate cerium .

[0027]

[0028] The base oil, in parts by weight, is composed of: 100 parts of polyalphaolefin synthetic base oil PAO, 10 parts of liquid paraffin; 5.5 parts of soybean lecithin, 0.3 part of monolaurin, and 2 parts of trimethylolpropane.

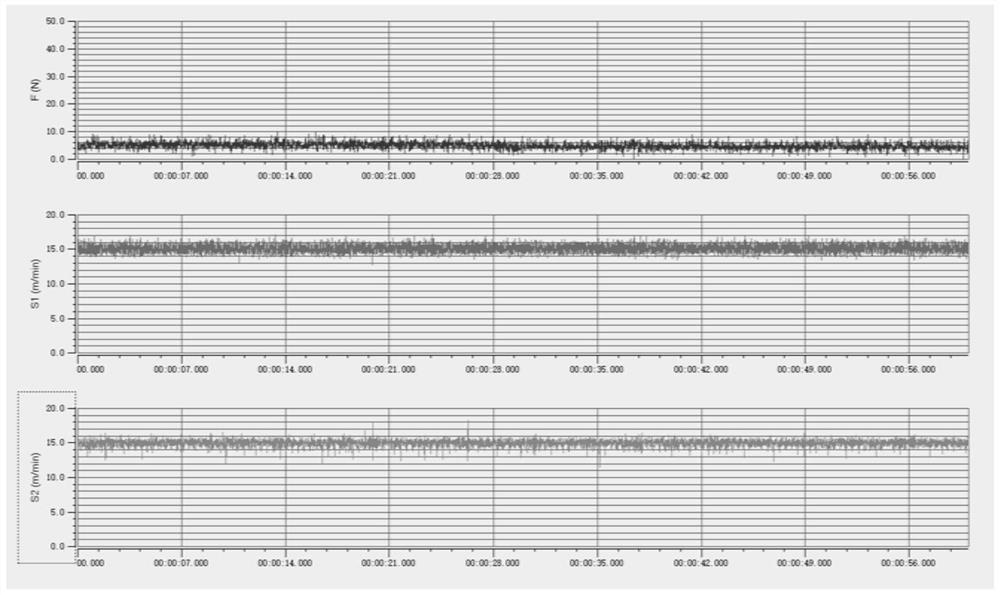

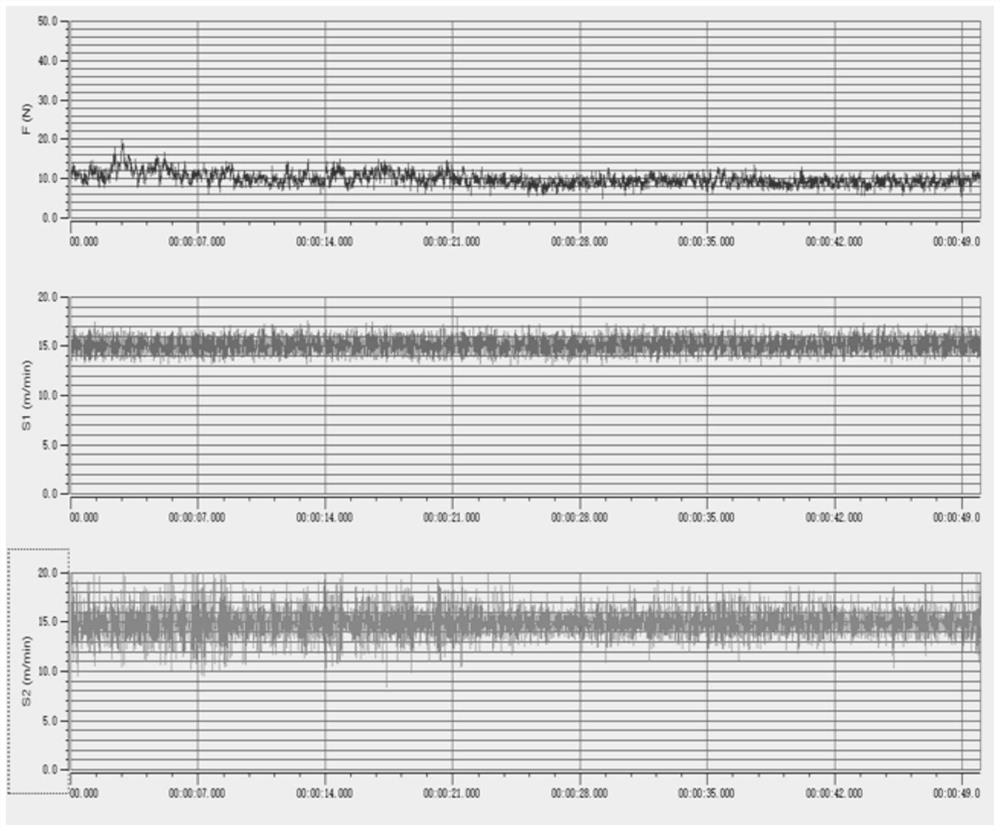

[0029] Figure 4 It is the appearance diagram of the welding seam after welding of the welding wire after the lubricating oil used in Example 1. It can be seen from the figure that the straightness of the outer edge of the welding seam surface is straight.

Embodiment 2

[0031] Synthetic lubricating and cleaning oil for aluminum alloy MIG welding wire, by weight, is composed of the following raw materials:

[0032] Extreme pressure antiwear additive 8%

[0033] Among them: the anti-wear additive is obtained by compounding 60% thiophosphoramidate, 0.05% 1-hydroxyethylidene-1,1-diphosphonic acid (dioctyl) ester (HEDP) and 39.95% cerium isooctyloxyborate .

[0034]

[0035] In parts by weight, the base oil is composed of: 100 parts of polyalphaolefin synthetic base oil PAO, 5 parts of liquid paraffin; 3.5 parts of soybean lecithin, 0.1 part of lauric acid monoglyceride, and 1 part of trimethylolpropane.

Embodiment 3

[0037] Synthetic lubricating and cleaning oil for aluminum alloy MIG welding wire, by weight, consists of the following raw materials:

[0038] Extreme pressure antiwear additive 3%

[0039] Among them: the anti-wear additive is obtained by compounding 70% thiophosphoramidate, 0.03% 1-hydroxyethylidene-1,1-diphosphonic acid (dioctyl) ester (HEDP) and 29.97% isooctyloxyborate cerium .

[0040]

[0041] The base oil, in parts by weight, is composed of: 100 parts of polyalphaolefin synthetic base oil PAO, 8 parts of liquid paraffin; 3.5 parts of soybean lecithin, 0.2 part of lauric acid monoglyceride, and 1.5 parts of trimethylolpropane ester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com