Landfill operation paving method for refuse landfill

A landfill technology, landfill technology, applied in landfill technology, solid waste removal, etc., can solve the problems of HDPE film operator hazards, increased operating time and protection costs, hidden safety hazards, etc., to achieve Improve construction efficiency, facilitate operation, and reduce protection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is attached Figure 1-3 The application is described in further detail.

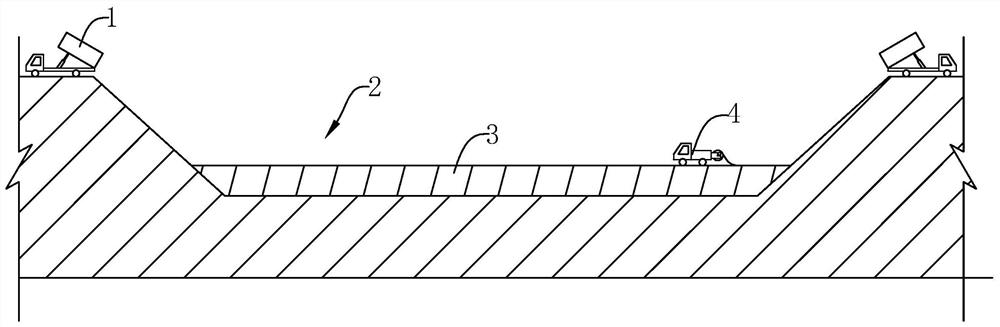

[0042] The embodiment of the present application discloses a paving method for landfill operation in a landfill site. refer to figure 1 and figure 2 , the landfill paving method for landfill includes the following construction steps:

[0043] S1: transport the sorted garbage to the landfill 2 through multiple transport vehicles 1, and the multiple transport vehicles 1 form a group of two, and each group of transport vehicles 1 dumps at two opposite positions above the landfill 2 Garbage, so that the garbage slides towards the bottom of the landfill 2 along the slope of the landfill 2, so as to provide a guarantee for the amount of garbage for subsequent paving operations.

[0044] S2: Move the garbage piled on the slope of the landfill 2 to the bottom of the landfill 2 by an excavator.

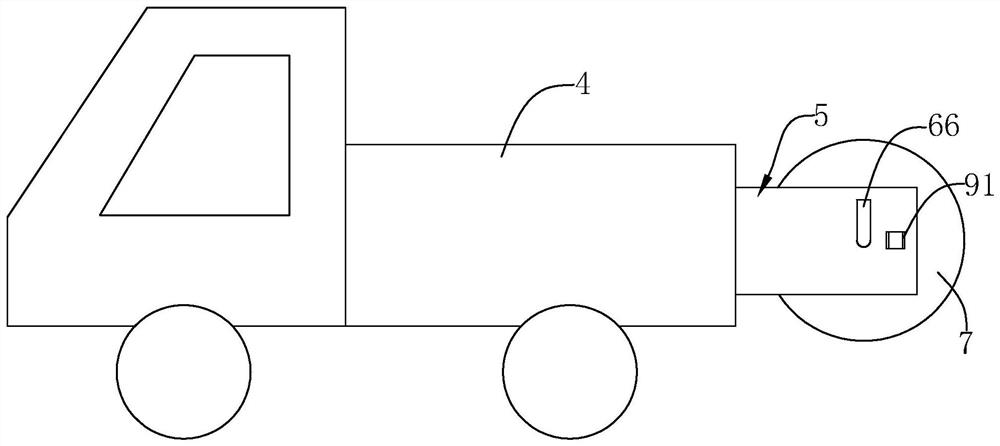

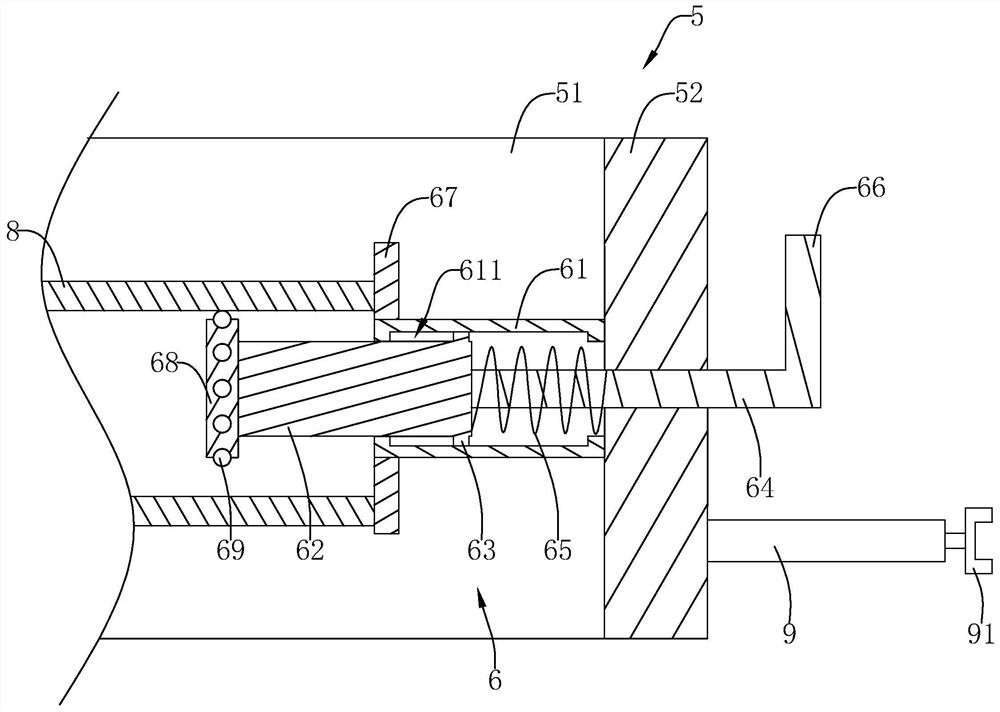

[0045] S3: Install at least two paving equipment in the landfill 2. The paving equipment ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com