Feed treatment device for animal husbandry

A processing device, animal husbandry technology, applied in the field of animal husbandry, can solve problems such as mixing troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

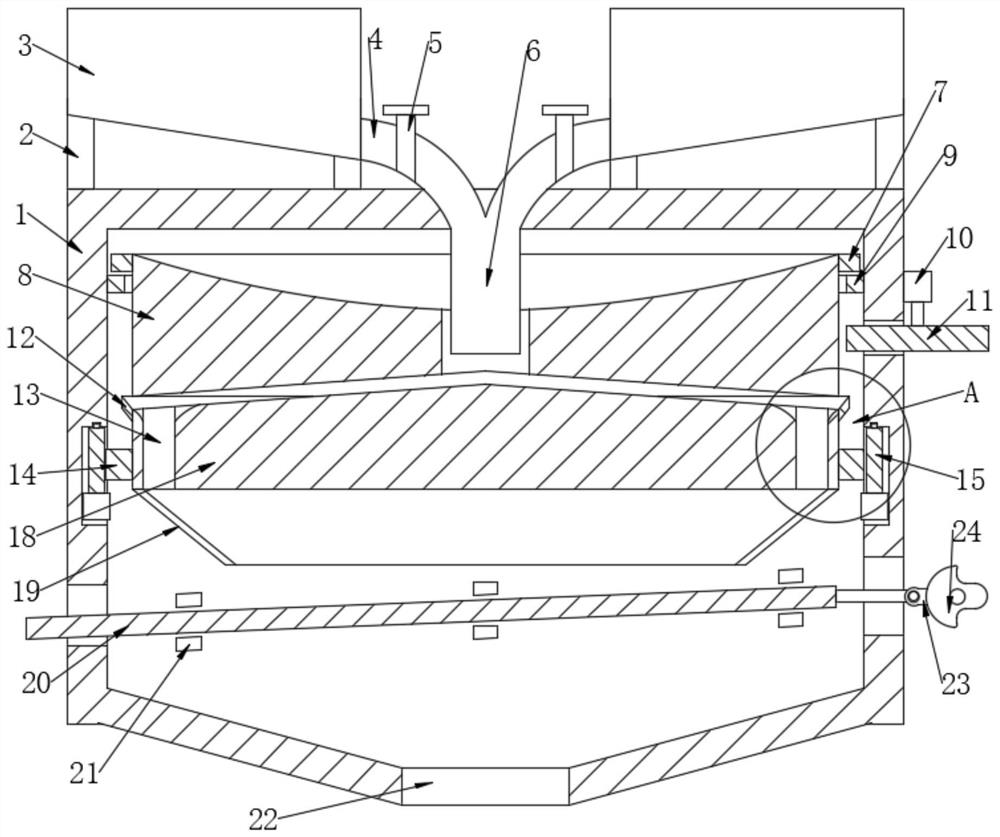

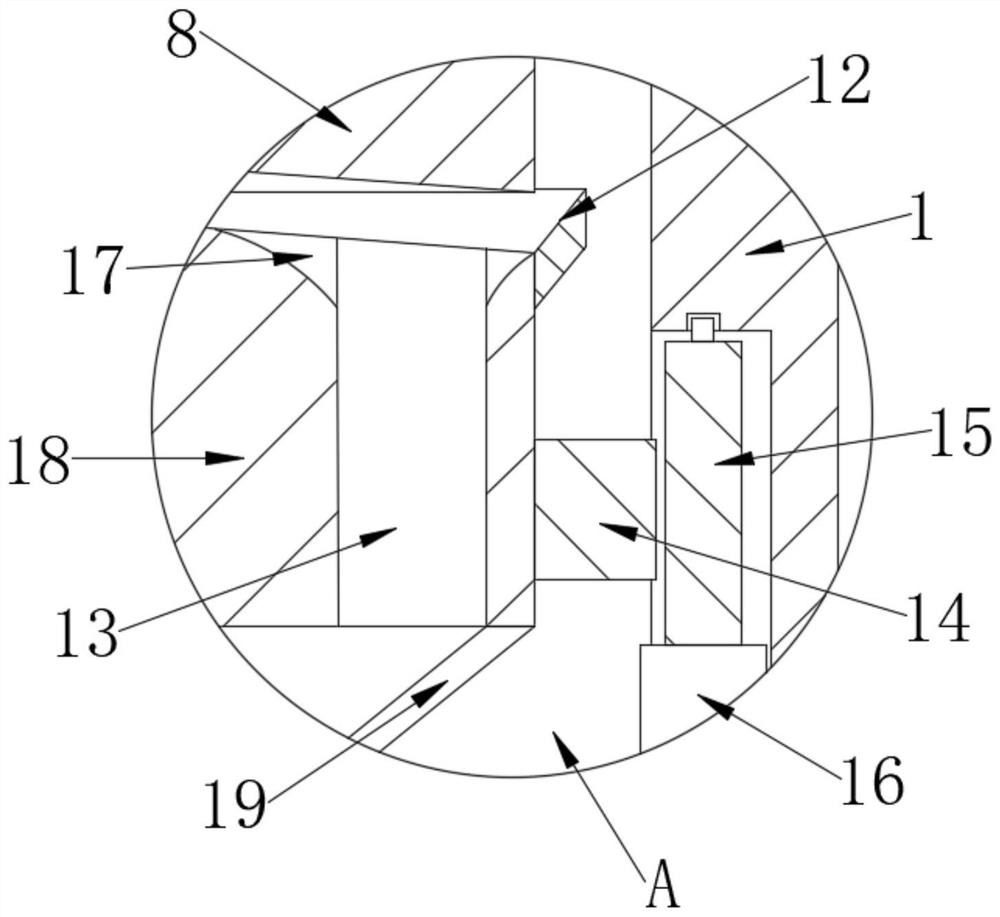

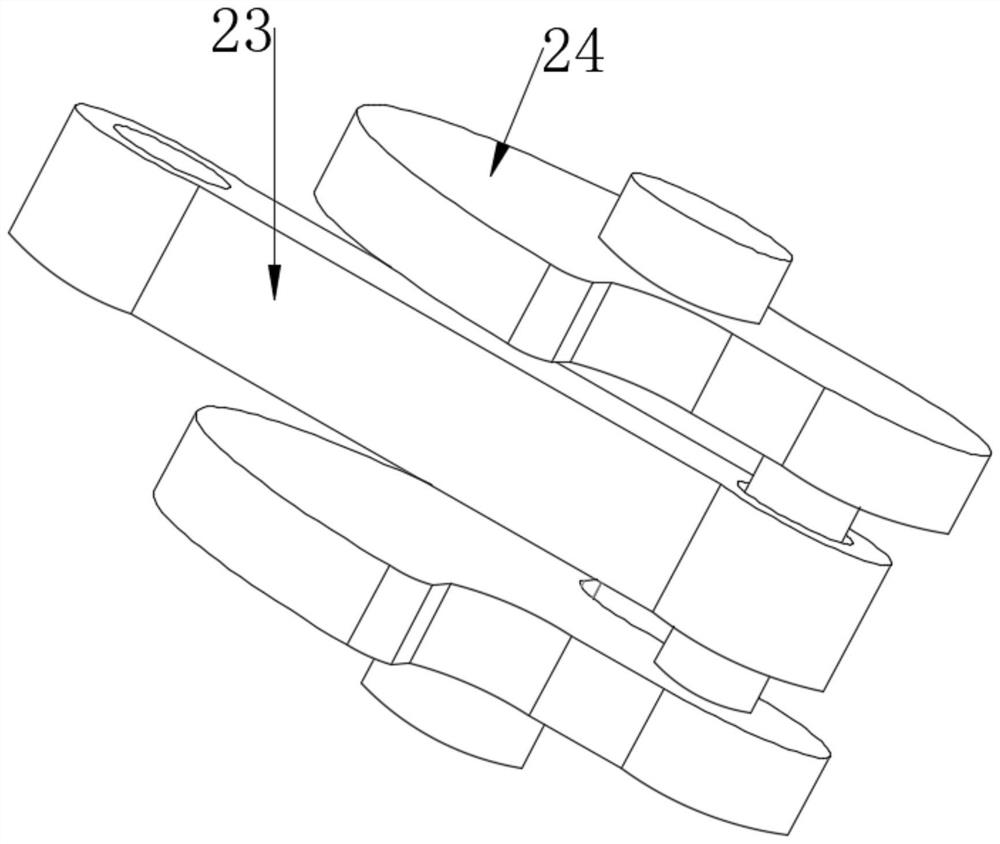

Embodiment 1

[0022] see Figure 1-3 , the present embodiment provides a feed processing device for animal husbandry, including a processing box 1, a material outlet 22 is provided at the bottom of the processing box 1 and a plurality of material storage bins 3 are arranged above it, and the processing box 1 A fixed pillar 2 for fixedly supporting the material storage bin 3 is arranged between the material storage bin 3, a material delivery pipe 4 is arranged at the lower end of the side of the material storage bin 3, and a flow control component is arranged on the material delivery pipe 4 5. A mixing input pipe 6 extending into the processing box 1 is also provided, and the mixing input pipe 6 is connected to the material delivery pipe 4, and a grinding mechanism and a screening structure are also arranged in the said 1, so The grinding mechanism includes an upper grinding roller 8 and a lower grinding roller 18 which are connected to each other and the height of the middle position of the...

Embodiment 2

[0033] On the basis of Embodiment 1, an adjustment mechanism is also provided, and the adjustment mechanism includes a threaded collar 14, an adjustment threaded rod 15 and an adjustment motor 16, and the adjustment motor 16 is fixedly arranged and driven to connect the adjustment threaded rod 15 , the threaded collar 14 is fixedly arranged on the lower grinding roller 18 and the adjusting threaded rod 15 is threaded, and under the driving action of the adjusting motor 16, the adjusting threaded rod 15 rotates, and when the threaded connection The height of the lower grinding roller 18 is changed under the effect of the action, and then the gap between the upper grinding roller 8 and the lower grinding roller 18 is changed, and finally the particle size of the material after grinding is changed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com