Method for processing meat products by high-temperature fermentation technology

A technology of fermented meat products and processing methods, applied in the direction of using chemicals to preserve meat/fish, food ingredients as antimicrobial preservation, food ingredients containing natural extracts, etc., which can solve the problems of difficult product quality control, poor sanitary conditions, production Long cycle and other issues, to achieve the effect of promoting production, improving safety and quality, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

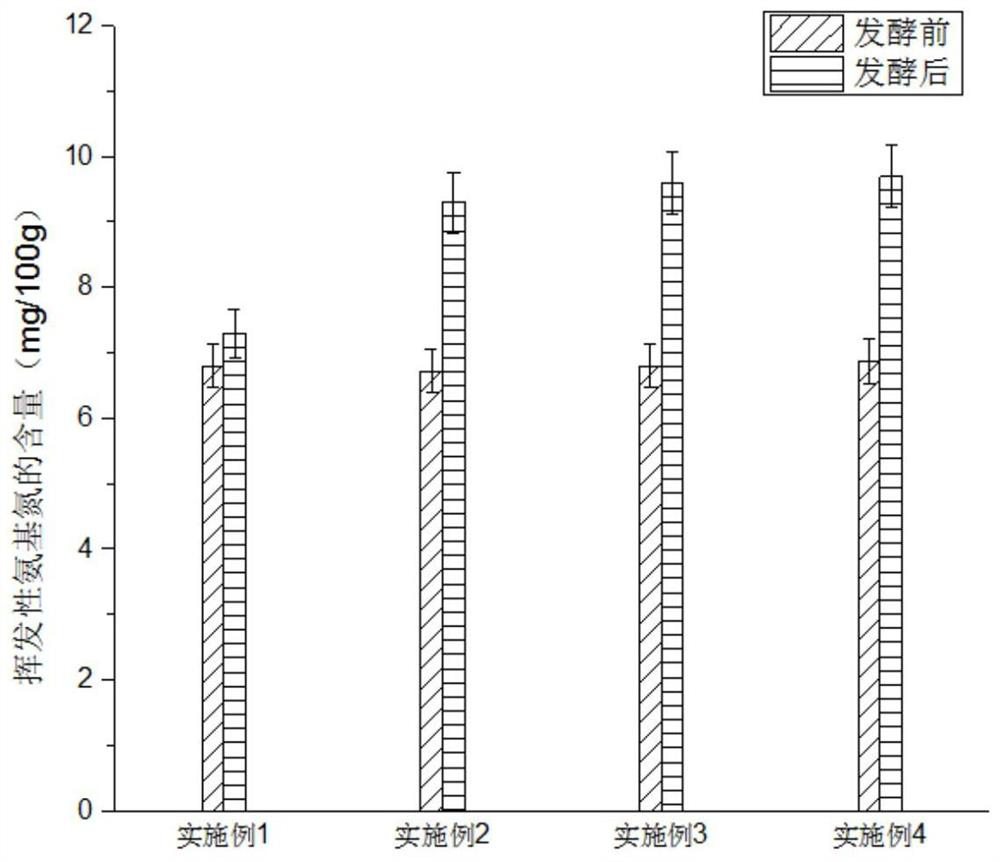

Embodiment 1

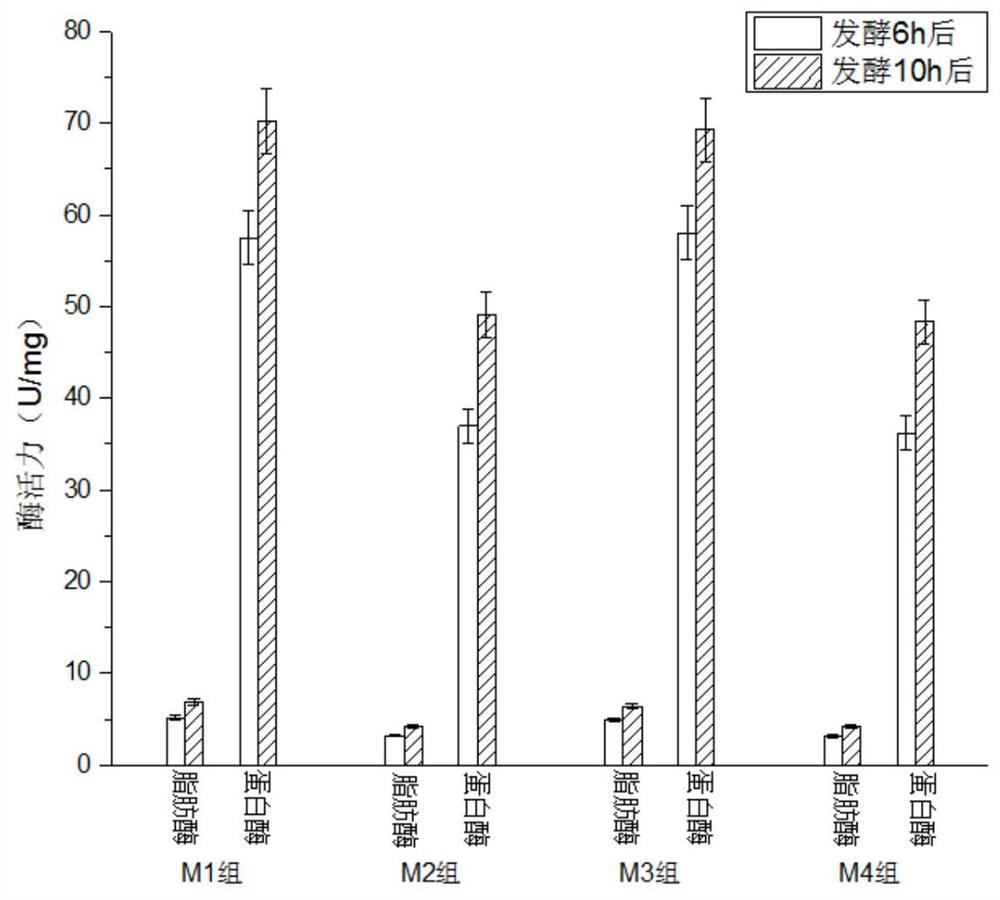

[0071] 1, a kind of processing method of fermented beef product, specifically comprises the following steps:

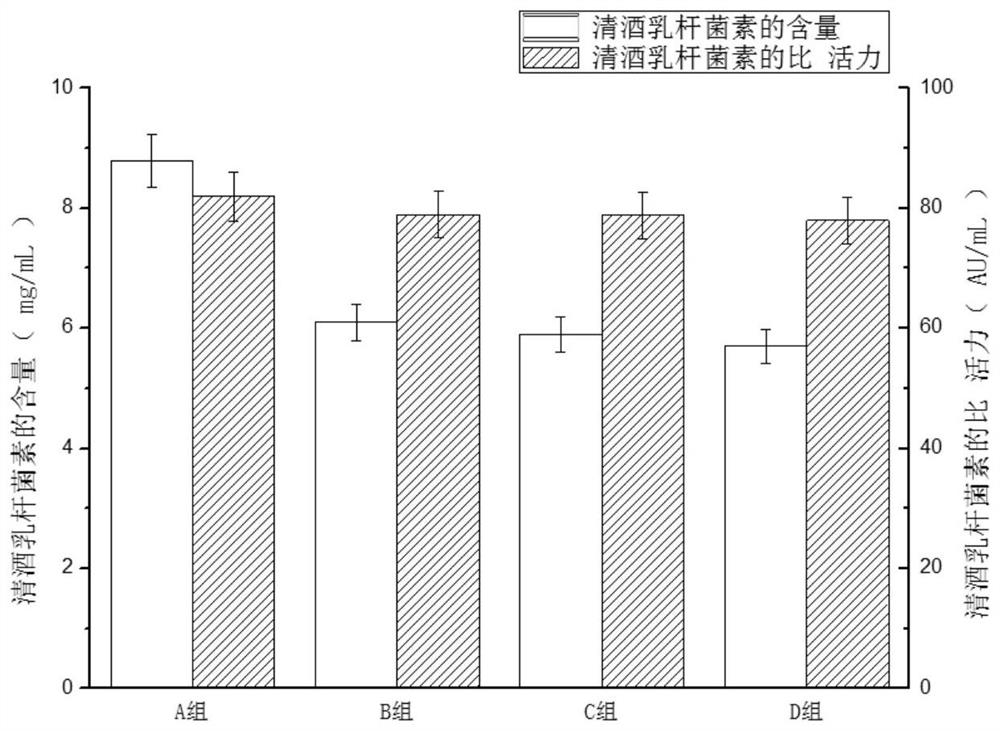

[0072] 1.1 Test materials: beef, Lactobacillus sake L.S-MA3-10, purchased from China Microbial Cultures Collection Committee General Microbiology Center, preservation number CGMCC No.0690; Pediococcus lactis CCFM7902, purchased from China Microbial Cultures Collection Management Committee Microbiology Center, collection number CGMCC No.5493; Staphylococcus calf DSM 15615, purchased from Lianmai Biotech; Staphylococcus carnosus, purchased from ATCC, United States, product number 51365; black soybean hull extract (containing 15wt% black soybean hull anthocyanins) , purchased from Shaanxi Ruicao Biotechnology Co., Ltd.; cocoa extract (containing 10wt% theobromine), purchased from Shaanxi Lvshengyuan Biological Products Manufacturing Co., Ltd., and sesame pollen, purchased from Xi'an Huageng Biotechnology Co., Ltd.

[0073] Ingredients: 3.2 parts of edible salt, 0.8 parts...

Embodiment 2

[0080] 1.4 Take 5kg of cured meat, dissolve 2.5g of starter and 7.5g of cocoa extract (containing 10wt% theobromine) into 200g of cooled boiled water, add it to the cured meat and stir evenly, keep the temperature at 38°C and humidity at 85°C %, under the condition of pH=5.5, ferment for 10 hours to obtain fermented meat. All the other parts are completely consistent with Example 1.

Embodiment 3

[0082] 1.4 Take 5kg of cured meat, dissolve 2.5g of starter and 16g of black soybean hull extract (containing 15wt% black soybean hull anthocyanins) into 200g of cooled boiled water, add it to the cured meat and stir evenly, and keep the temperature at 38°C , Humidity 85%, pH=5.5 conditions, fermentation 10h, obtain fermented meat. All the other parts are completely consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com