A kind of preparation method of Taiwan flavor sausage convenient for preservation

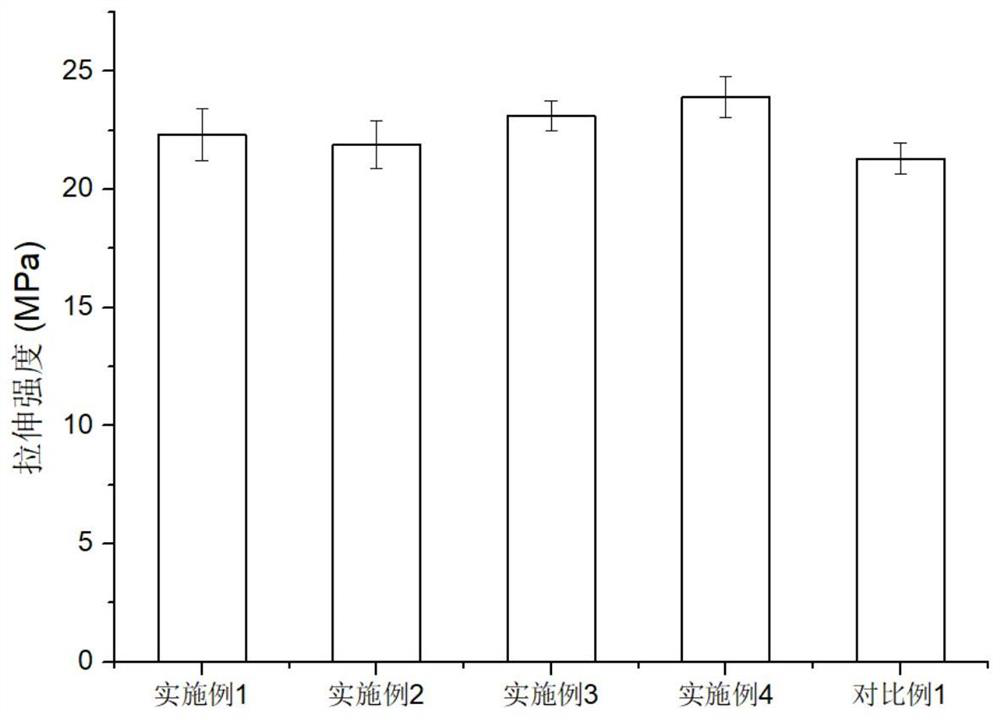

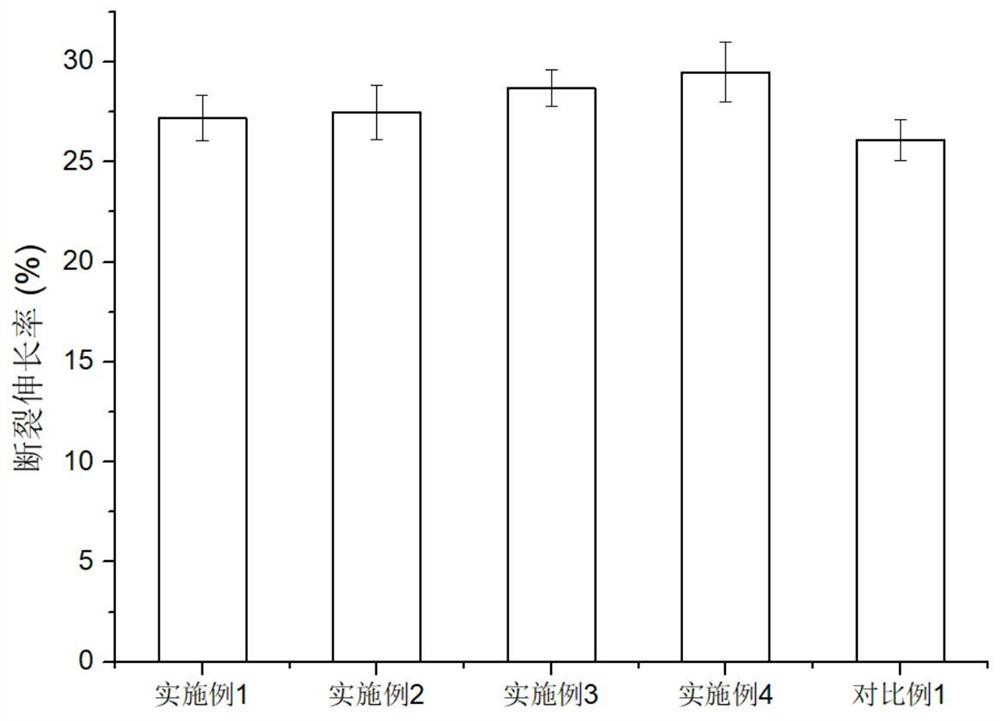

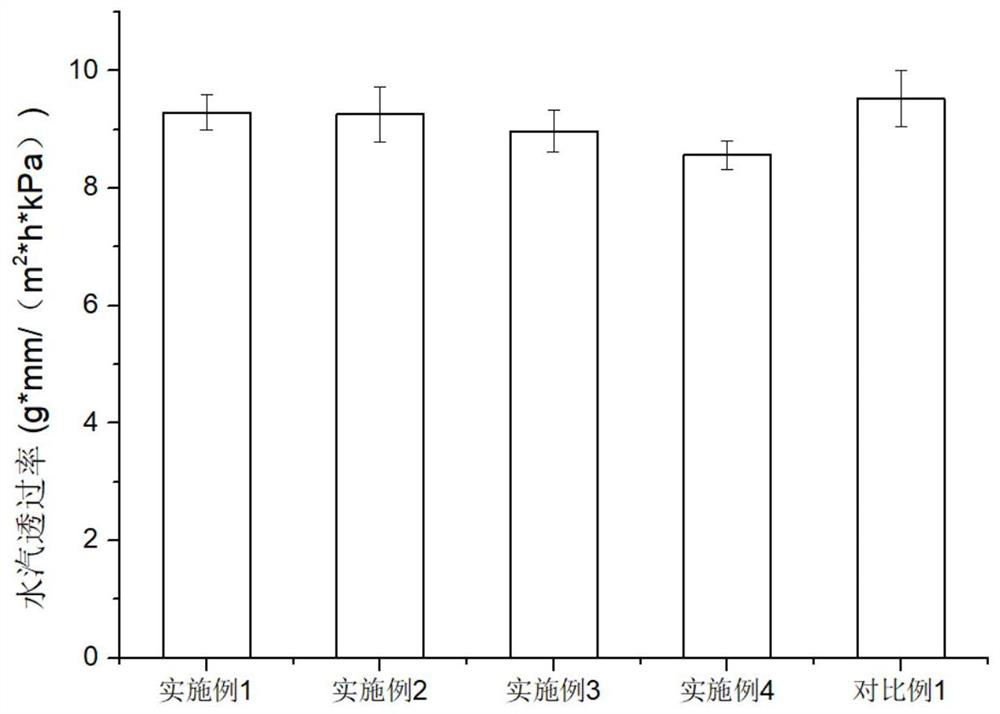

A sausage and flavor technology, which is applied in the field of preparation of desktop flavor sausages, can solve the problems of easy falling off of casing film, unspecified meat stickiness, insufficient stickiness, etc., and achieves the effects of good preservation effect, low water vapor transmission rate and good stickiness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of preparation method of enteric coating film,

[0043]Enteric coating film preparation: Add collagen, soybean protein, chitosan, glycerin, glutaraldehyde, and isolicorice flavonol to distilled water, adjust the pH to 10, and mix evenly at a temperature of 40°C to obtain a film-forming solution. The solution was uniformly cast on a glass mold, dried in a blast drying oven at a temperature of 50°C for 40 minutes, and finally placed in a constant humidity dryer at a temperature of 25°C and a humidity of 50% for 48 hours to obtain a sausage casing film. The addition of collagen is 9wt% of distilled water; the addition of soybean protein is 5wt% of distilled water; the addition of chitosan is 3wt% of distilled water; the addition of glycerin is 50wt% of distilled water; the addition of glutaraldehyde It is 0.16wt% of distilled water; the addition amount of isoflavonol is 3wt% of distilled water.

Embodiment 2

[0045] A kind of preparation method of enteric coating film,

[0046] Enteric coating film preparation: add collagen, soybean protein, chitosan, glycerin, glutaraldehyde, and glucosyl apigenin to distilled water, adjust the pH to 10, and mix evenly at a temperature of 40°C to obtain a film-forming solution. The solution was uniformly cast on a glass mold, dried in a blast drying oven at a temperature of 50°C for 40 minutes, and finally placed in a constant humidity dryer at a temperature of 25°C and a humidity of 50% for 48 hours to obtain a sausage casing film. The addition of collagen is 9wt% of distilled water; the addition of soybean protein is 5wt% of distilled water; the addition of chitosan is 3wt% of distilled water; the addition of glycerin is 50wt% of distilled water; the addition of glutaraldehyde It is 0.16wt% of distilled water; the addition amount of glucosyl apigenin is 3wt% of distilled water.

Embodiment 3

[0048] A kind of preparation method of enteric coating film,

[0049] Enteric coating film preparation: add collagen, soybean protein, chitosan, glycerin, glutaraldehyde, isolicorice flavonol and glucosyl apigenin to distilled water, adjust the pH to 10, and mix evenly at a temperature of 40°C to obtain a film-forming solution , the film-forming solution was evenly cast on the glass mold, dried in a blast drying oven at a temperature of 50°C for 40 minutes, and finally placed in a constant humidity dryer at a temperature of 25°C and a humidity of 50% for 48 hours to obtain sausage casings membrane. The addition of collagen is 9wt% of distilled water; the addition of soybean protein is 5wt% of distilled water; the addition of chitosan is 3wt% of distilled water; the addition of glycerin is 50wt% of distilled water; the addition of glutaraldehyde It is 0.16wt% of distilled water; the addition amount of isolicorice flavonol is 1wt% of distilled water; the addition amount of gluc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com