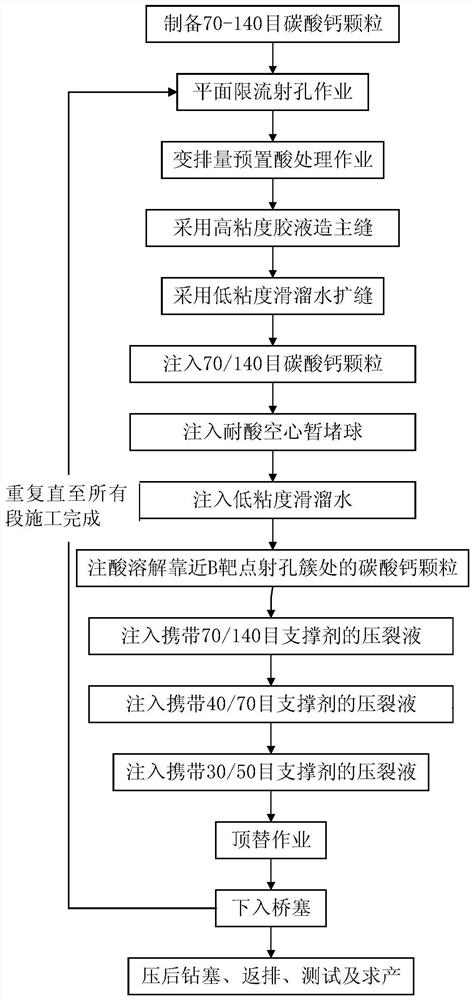

A horizontal well fracturing method that promotes high fracture extension through two acid injections and inter-cluster temporary plugging

A horizontal well and acid injection technology, applied in the field of horizontal well fracturing, can solve the problem of limited height of fracturing fractures, and achieve the effects of increasing construction displacement, increasing production length, and efficient development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A shale gas well in southwestern Sichuan has a vertical depth of 2200m, a sounding depth of 4385m and a horizontal section length of 1585m. Follow these steps to retrofit:

[0074] (1) Use coiled tubing to carry perforating guns to complete the first stage of perforating operations. Among them, the perforating guns are arranged with 3 holes in each plane, the number of perforation clusters is 6 clusters, and there are 18 perforation holes in total.

[0075] (2) After the first stage of perforating operation, take 1m 3 A total of 30m of pretreatment acid is injected at the displacement of / min 3 . Then take 4m 3 Displacement / min injected into low viscosity slick water 16m 3 acid. The displacement was subsequently increased to 6m 3 / min inject low viscosity slick water 16m 3 Replace the acid, and finally increase the displacement to 8m 3 Inject 18m of low-viscosity slick water / min 3 Replace the acid to ensure that the acid can enter all perforation clusters.

...

Embodiment 2

[0097] A shale gas well in southwestern Sichuan has a vertical depth of 2600m, a sounding depth of 4886m and a horizontal section length of 1585m. Follow these steps to retrofit:

[0098] (1) Use coiled tubing to carry perforating guns to complete the first stage of perforating operations. Among them, the perforating guns are arranged with 3 holes in each plane, the number of perforation clusters is 6 clusters, and there are 18 perforation holes in total.

[0099] (2) After the first stage of perforating operation, use 1.5m 3 A total of 30m of pretreatment acid is injected at the displacement of / min 3 . Then take 4m 3 Displacement / min injected into low viscosity slick water 16m 3 acid. The displacement was subsequently increased to 6m 3 / min inject low viscosity slick water 16m 3 Replace the acid, and finally increase the displacement to 8m 3 Inject 18m of low-viscosity slick water / min 3 Replace the acid to ensure that the acid can enter all perforation clusters. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com