Process for replacing with fiber Wuben wood residue pulp in papermaking

A technology of uben and wood residue, which is applied in the direction of non-fibrous pulp addition, papermaking, papermaking machines, etc., can solve the problems of low production cost and insufficient production capacity, improve the bursting strength, reduce the amount of US waste, and ensure paper production quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

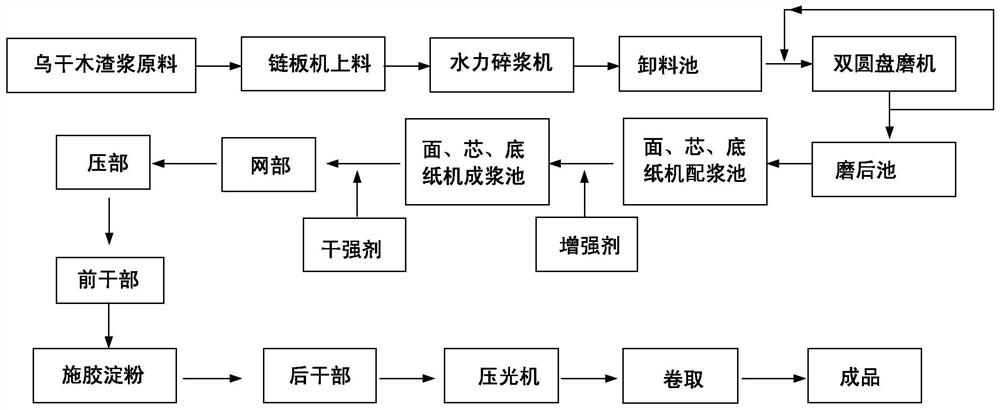

[0012] In order to make the technical solution of the present invention more clearly expressed, the present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the present invention provides a papermaking substitute fiber uben wood pulp process for producing finished paper, and the papermaking fiber substitute uben wood pulp process comprises the following steps:

[0014] (1) The uben wood pulp raw material is fed into the hydraulic pulper through the chain plate machine for disintegration, and after being disintegrated by the disintegrator, it enters the unloading tank. The unloading tank is connected to the entrance of the double-disc mill. The outlet of the disc refiner is connected to the post-grinding tank, and the other port of the double-disc refiner is connected to the inlet of the double-disc refiner. The produced secondary good pulp is returned to the inlet and ground again on the double disc r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com