In-situ reagent injection remediation method for soil and underground water pollution

A groundwater pollution and repair method technology, which is applied in the field of in-situ chemical injection repair of soil and groundwater pollution, can solve problems such as insufficient local drug injection, secondary pollution, and situation mismatch, so as to reduce the risk of secondary pollution and save energy. Equipment cost, effect of preventing lateral disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

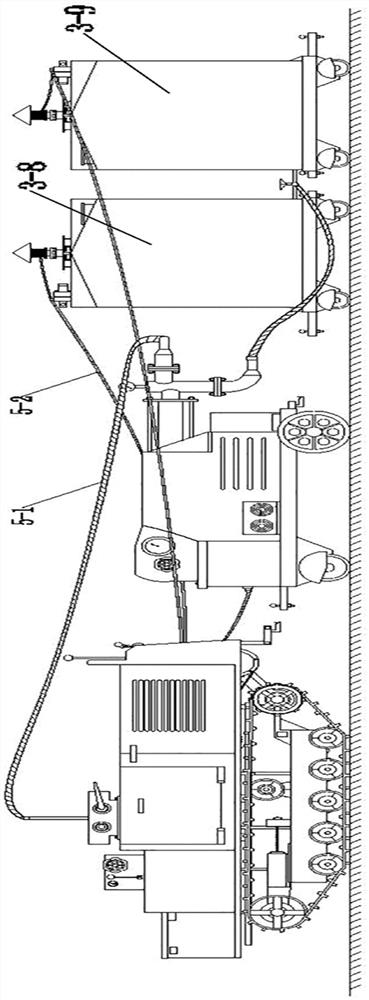

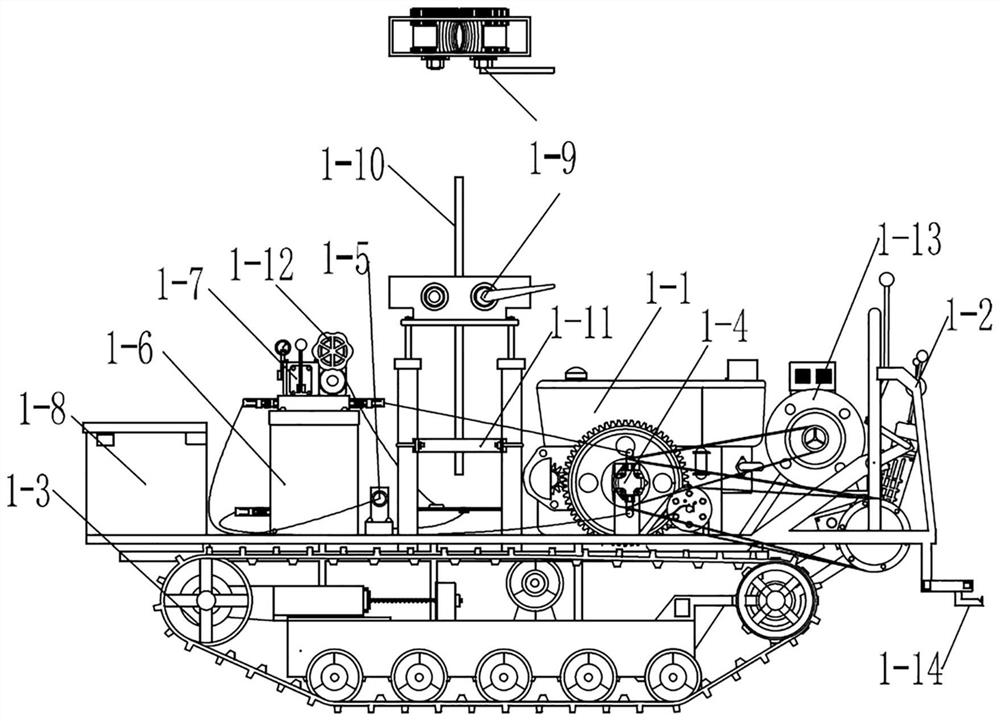

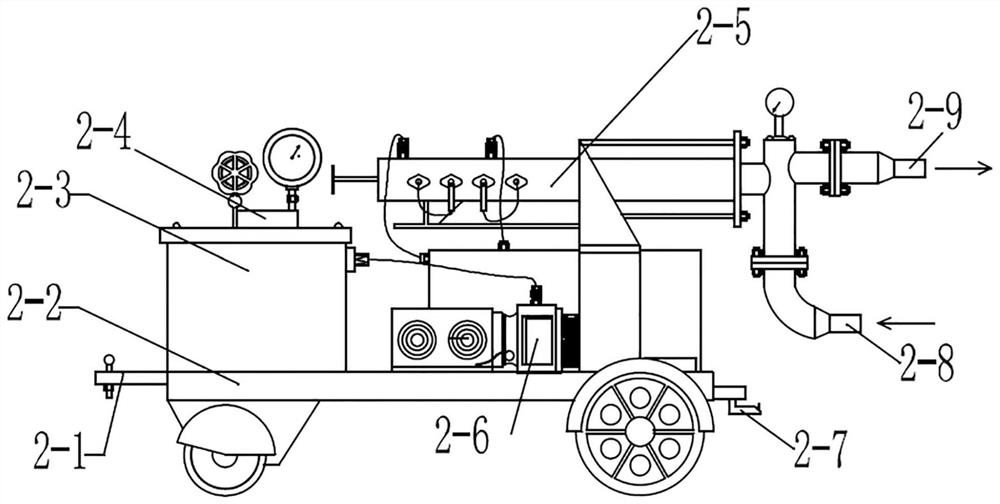

[0056] An in-situ agent injection restoration method for soil and groundwater pollution, using integrated equipment for in-situ agent injection restoration.

[0057] The equipment includes power system, detection system, injection system, dispensing system and auxiliary system. Power system includes fuel engine 1-1, power control mechanism 1-2, gearbox and generator 1-13; detection system includes probe 4-4, probe rod 4-3, data cable and computer 4-5; injection system Including plunger pump 2-5, injection rod 4-1, injection head 4-2, injection control mechanism and injection trolley platform 2-2; the dispensing system includes drug dissolving tank 3-5, stirring mechanism 3-2, adding The medicine metering mechanism and the dispensing trolley platform 3-7; the auxiliary system includes a rod box 1-8, a crawler chassis 1-3, a pressing hydraulic device and a pressing mechanism 1-9.

[0058] Engine 1-1, gear pump 1-4, hydraulic check valve 1-5, hydraulic cylinder 1-6, electromagne...

Embodiment 2

[0068] An in-situ chemical injection repair method for soil and groundwater pollution, which was applied to a small polycyclic aromatic hydrocarbon-contaminated site for soil risk control and repair site.

[0069] The pollution depth of the target area is about 3.0m. According to the scope of the target area, a total of 11 injection holes are designed, the design injection depth is 0.5m-1.5m-3.0m, and the design influence radius of a single hole is 1.5m.

[0070] No diving was found in the site. Due to the long history of the site and the backfilling time of more than 10 years, the distribution of soil layers is extremely uneven, and pollutants are distributed in multiple layers. Obviously, the traditional injection construction method cannot achieve the expected restoration goals.

[0071] Therefore, the in-situ formation detection-in-situ drug injection method is chosen, which is realized by the integrated restoration drug injection device of the present invention, which incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandwidth | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com