Preparation method of foam joint sealant

A gap filler and foam technology, used in chemical instruments and methods, dissolving, mixers, etc., can solve problems such as unfavorable overall cleaning, ratio error, low overall efficiency, etc., to maintain cleanliness, avoid cross-contamination, and Improves the effect of thorough mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

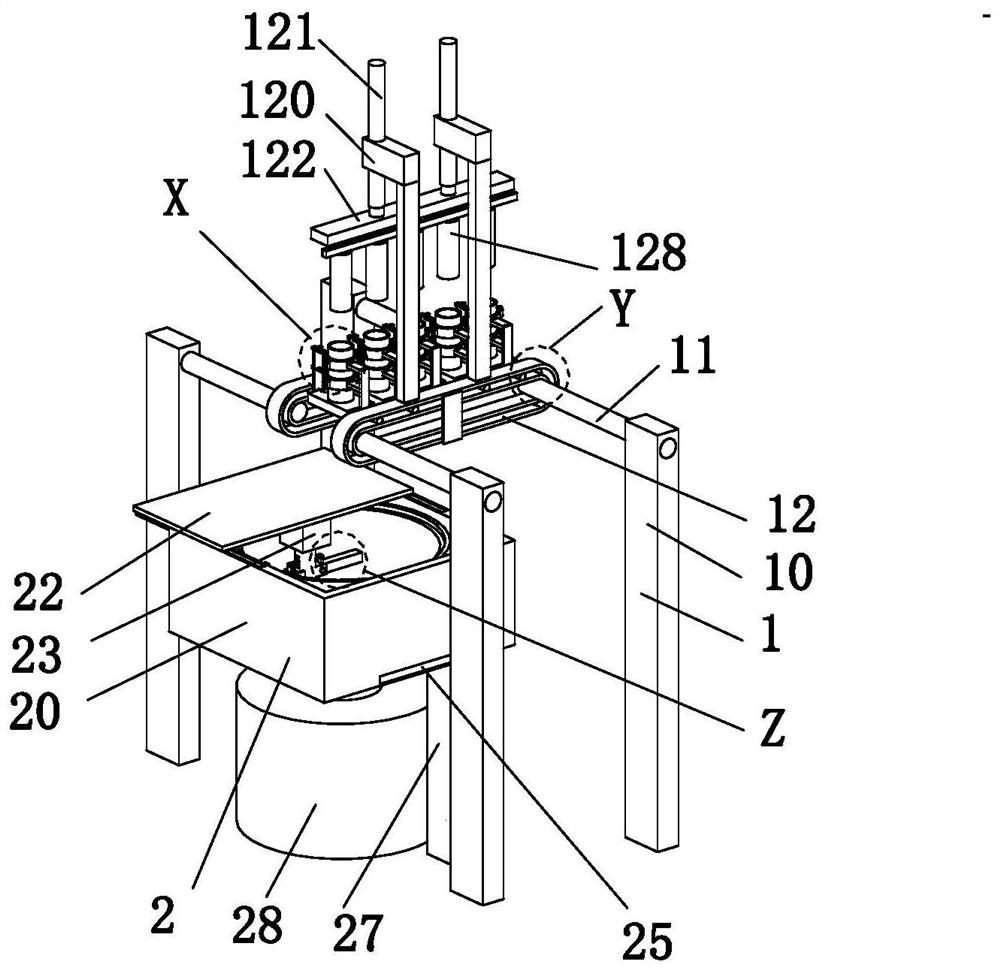

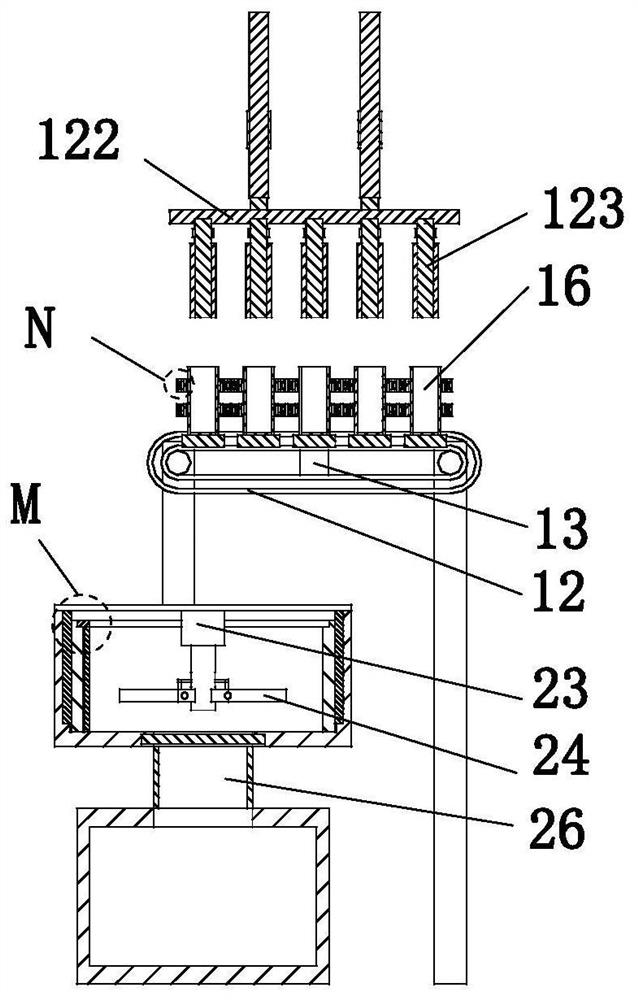

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

[0037] Such as Figure 1 to Figure 10 As shown, a method for preparing a foam sealant, which uses a foam sealant preparation device, the foam sealant preparation device includes a batching mechanism 1 and a stirring and pouring mechanism 2, using the above-mentioned foam sealant preparation device to carry out The specific preparation method of the foam sealant is as follows:

[0038] S1. Raw material ratio: Put the prepared raw materials into a single measuring cylinder 16 manually, and control the amount of raw materials put in by observing the change of the data displayed by the weighing device 15 to form a corresponding ratio;

[0039] S2. Stirring and mixing: After the raw materials in the measuring cylinder 16 fall into the mixing tank 20,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com