Axial flux five-degree-of-freedom magnetic levitation motor

A technology of axial magnetic flux and degree of freedom, applied in the direction of magnetic circuits, electric components, electrical components, etc., can solve problems such as inability to achieve axially stable suspension, and achieve strong fault tolerance, high reliability, and large axial bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals denote the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

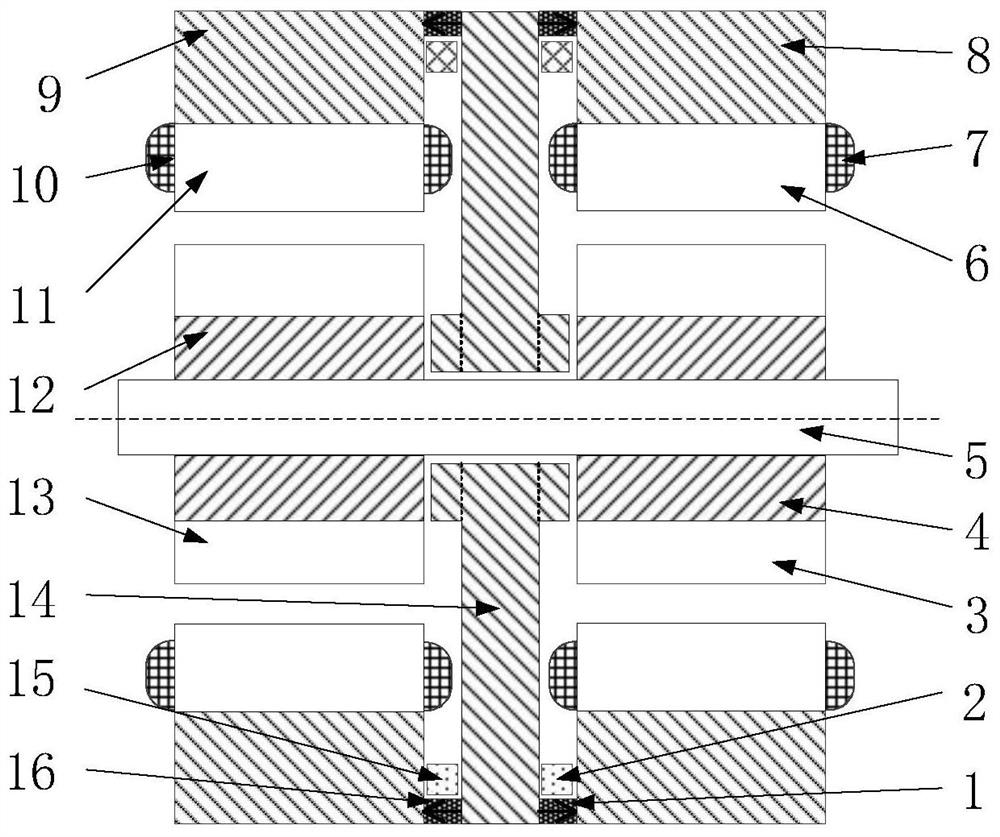

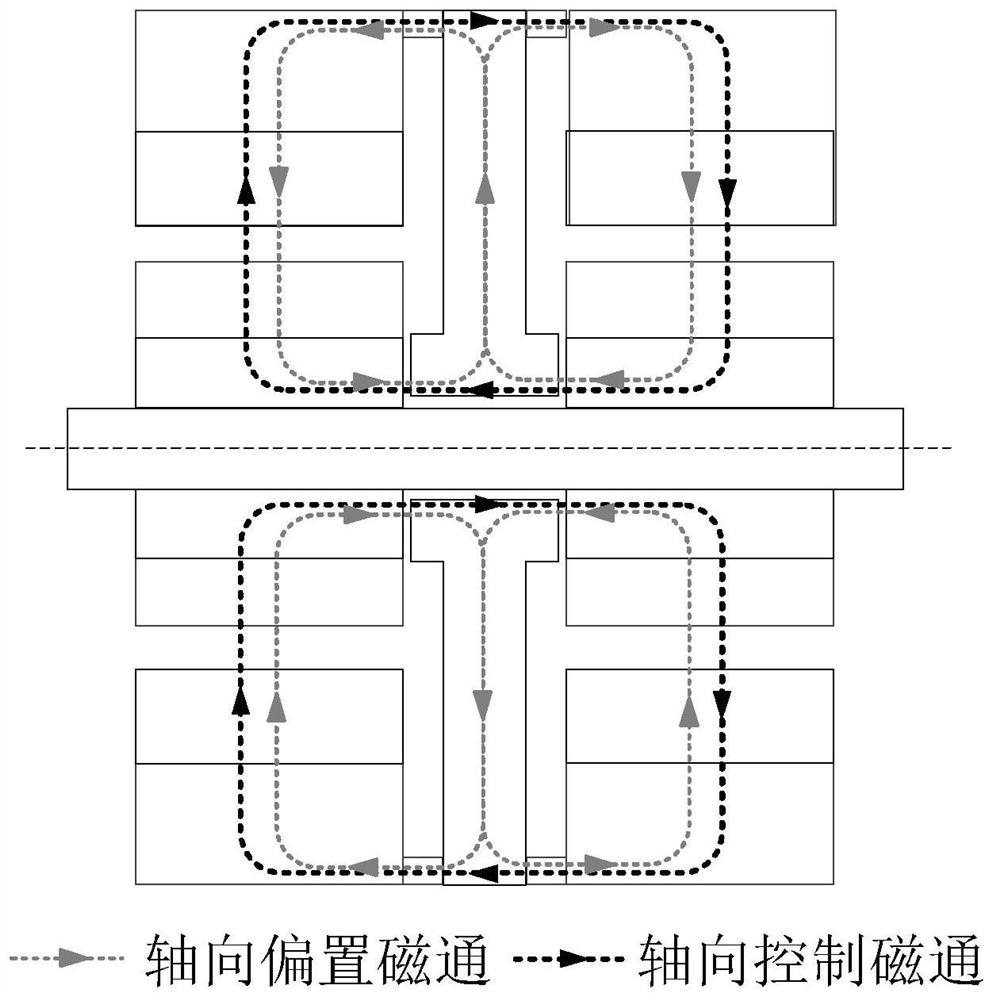

[0022] Such as figure 1 As shown, the plan view of the axial flux five-degree-of-freedom magnetic levitation motor proposed by the present invention includes a first bearingless switched reluctance motor, a second bearingless switched reluctance motor, an axial disc 14, and a first permanent magnet ring 1 , the second permanent magnet ring 16, the first axial control winding 2, the second axial control winding 15; the first bearingless switched reluctance motor has the same structure as the second bearingless switched reluctance motor, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com