VO2(B)/carbon cloth self-supporting material as well as preparation method and application thereof

A self-supporting, VO2 technology, applied in the field of nanomaterials and electrochemistry, can solve the problems of increasing VO2 polarization, reducing the electronic conductivity of active materials, degrading the electrochemical performance of electrode materials, etc., achieving excellent cycle stability and facilitating marketization Promotional, easy-to-magnify effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] VO 2 (B) The preparation method of carbon cloth self-supporting material, it comprises the steps:

[0029] 1) 0.3638g vanadium pentoxide (V 2 o 5 ) and 0.7564g oxalic acid (C 2 h 2 o 4 2H 2 O) add 12mL of distilled water, and react under the condition of heating in a water bath at 75° C. to obtain a blue clear solution;

[0030] 2) Add 3mL of 30% H 2 o 2 solution, stir well;

[0031] 3) Add 65mL of absolute ethanol and stir evenly to obtain a precursor solution;

[0032]4) Transfer the precursor solution obtained in step 3) to the reactor, and put it into carbon cloth for hydrothermal reaction. The hydrothermal temperature is 180°C, and the hydrothermal time is 100 minutes;

[0033] 5) The obtained active material was washed several times with pure water, and then dried in a vacuum oven at 60°C to finally obtain VO 2 (B) / Carbon cloth self-supporting material.

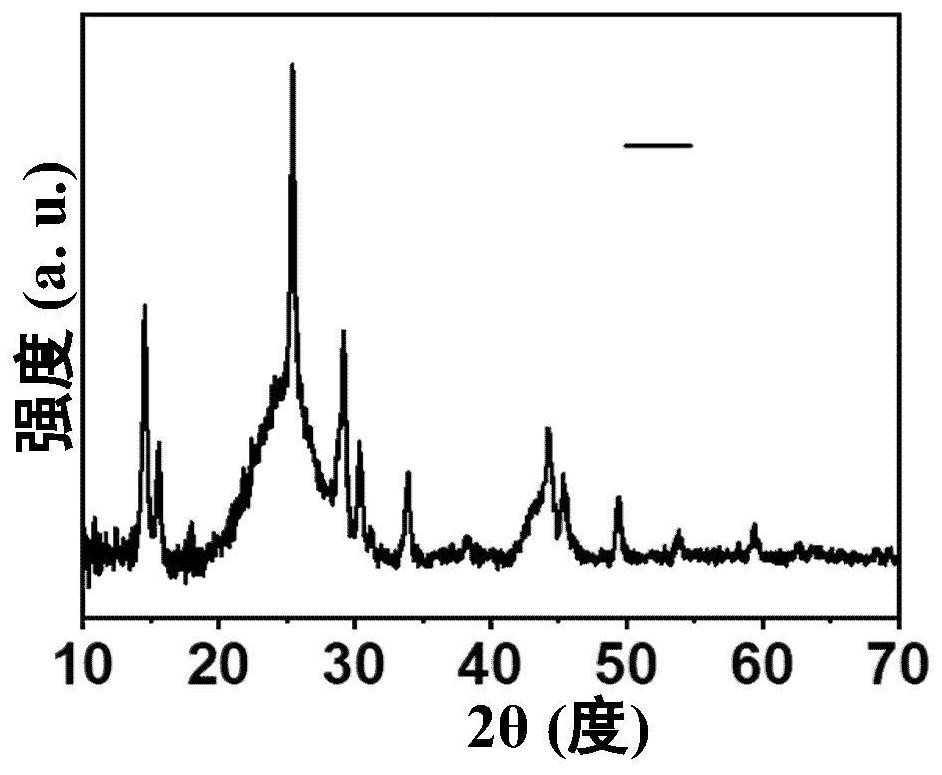

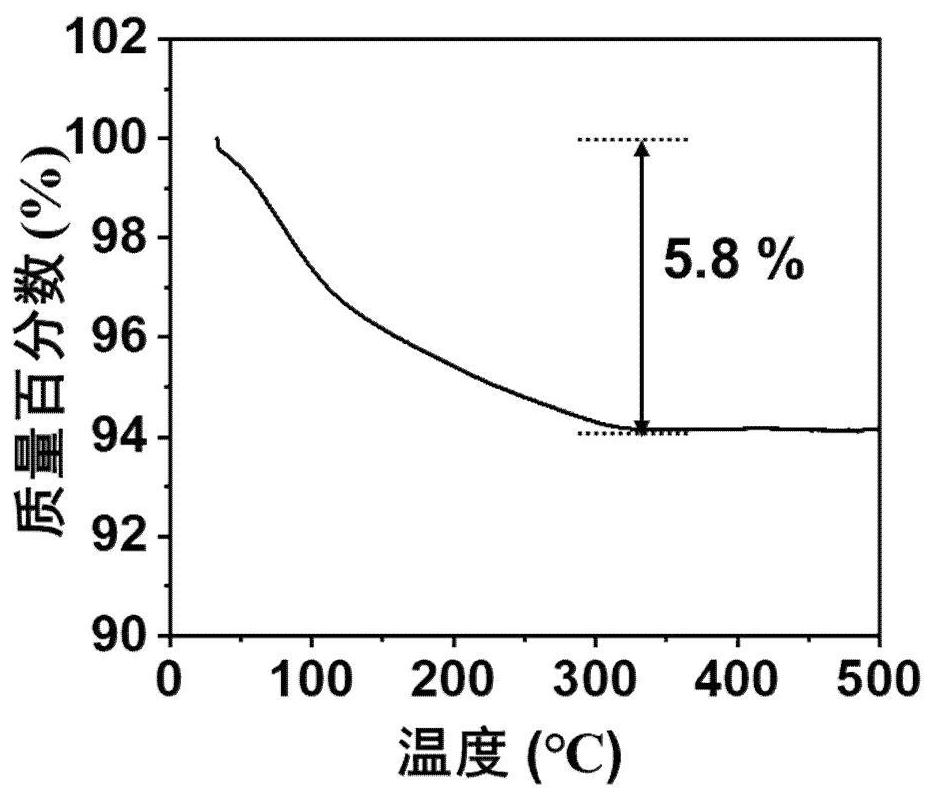

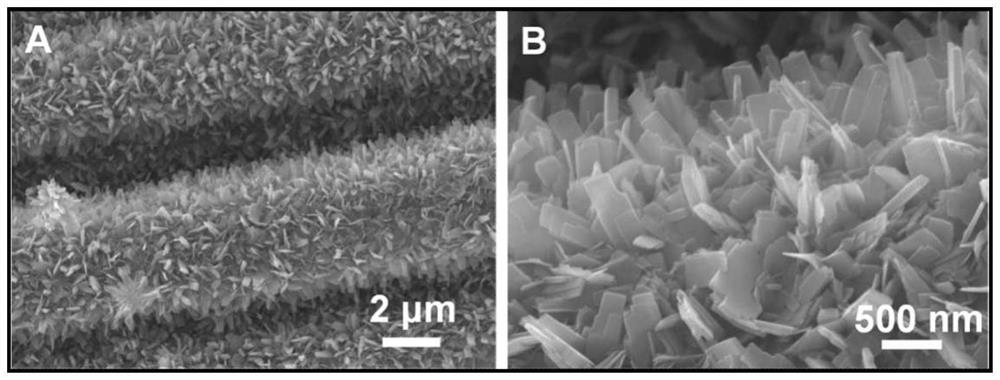

[0034] With the product VO of the present invention 2 (B) / Carbon cloth self-supporting material ...

Embodiment 2

[0039] VO 2 (B) The preparation method of carbon cloth self-supporting material, it comprises the steps:

[0040] 1) 0.3638g vanadium pentoxide (V 2 o 5 ) and 0.7564g oxalic acid (C 2 h 2 o 4 2H 2 O) adding 12mL of distilled water, reacting under the condition of heating in a water bath at 70°C to obtain a blue clear solution;

[0041] 2) Add 3mL of 30% H 2 o 2 solution, stir well;

[0042] 3) Add 65mL of absolute ethanol and stir evenly to obtain a precursor solution;

[0043] 4) Transfer the precursor solution obtained in step 3) to a reaction kettle, and put carbon cloth into it for hydrothermal reaction. The hydrothermal temperature is 170°C, and the hydrothermal time is 90 minutes;

[0044] 5) The obtained active material was washed several times with pure water, and then dried in a vacuum oven at 70°C to finally obtain VO 2 (B) / Carbon cloth self-supporting material.

[0045] VO obtained in this example 2 (B) / carbon cloth self-supporting material as an examp...

Embodiment 3

[0047] VO 2 (B) The preparation method of carbon cloth self-supporting material, it comprises the steps:

[0048] 1) 0.3638g vanadium pentoxide (V 2 o 5 ) and 0.7564g oxalic acid (C 2 h 2 o 4 2H 2 O) adding 12mL of distilled water, reacting under the condition of heating in a water bath at 80°C to obtain a blue clear solution;

[0049] 2) Add 3mL of 30% H 2 o 2 solution, stir well;

[0050] 3) Add 65mL of absolute ethanol and stir evenly to obtain a precursor solution;

[0051] 4) Transfer the precursor solution obtained in step 3) to a reaction kettle, and put carbon cloth into it for hydrothermal reaction. The hydrothermal temperature is 190°C, and the hydrothermal time is 80 minutes;

[0052] 5) The obtained active material was washed several times with pure water, and then dried in a vacuum oven at 80°C to finally obtain VO 2 (B) / Carbon cloth self-supporting material.

[0053] VO obtained in this example 2 (B) / carbon cloth self-supporting material as an examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com